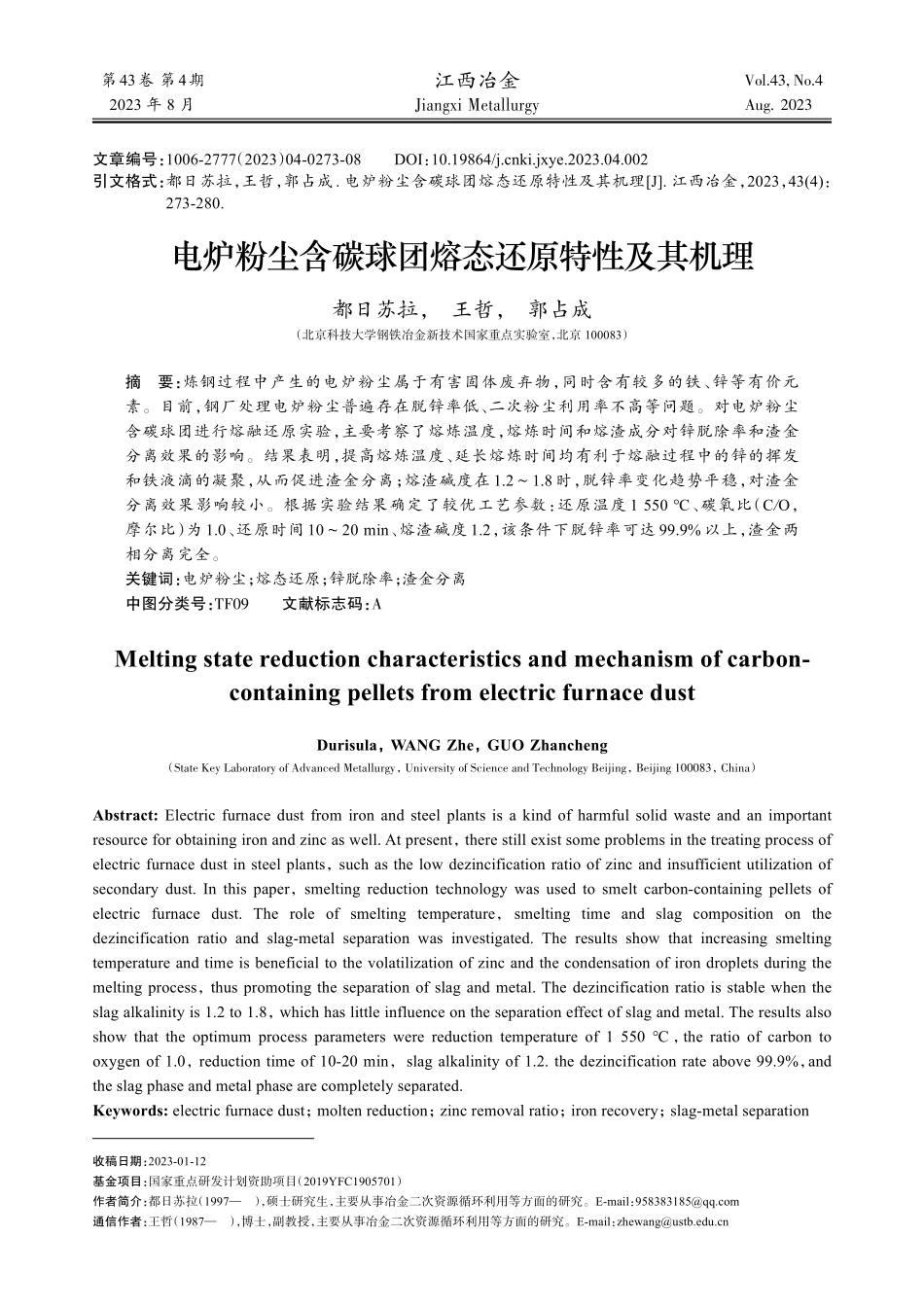

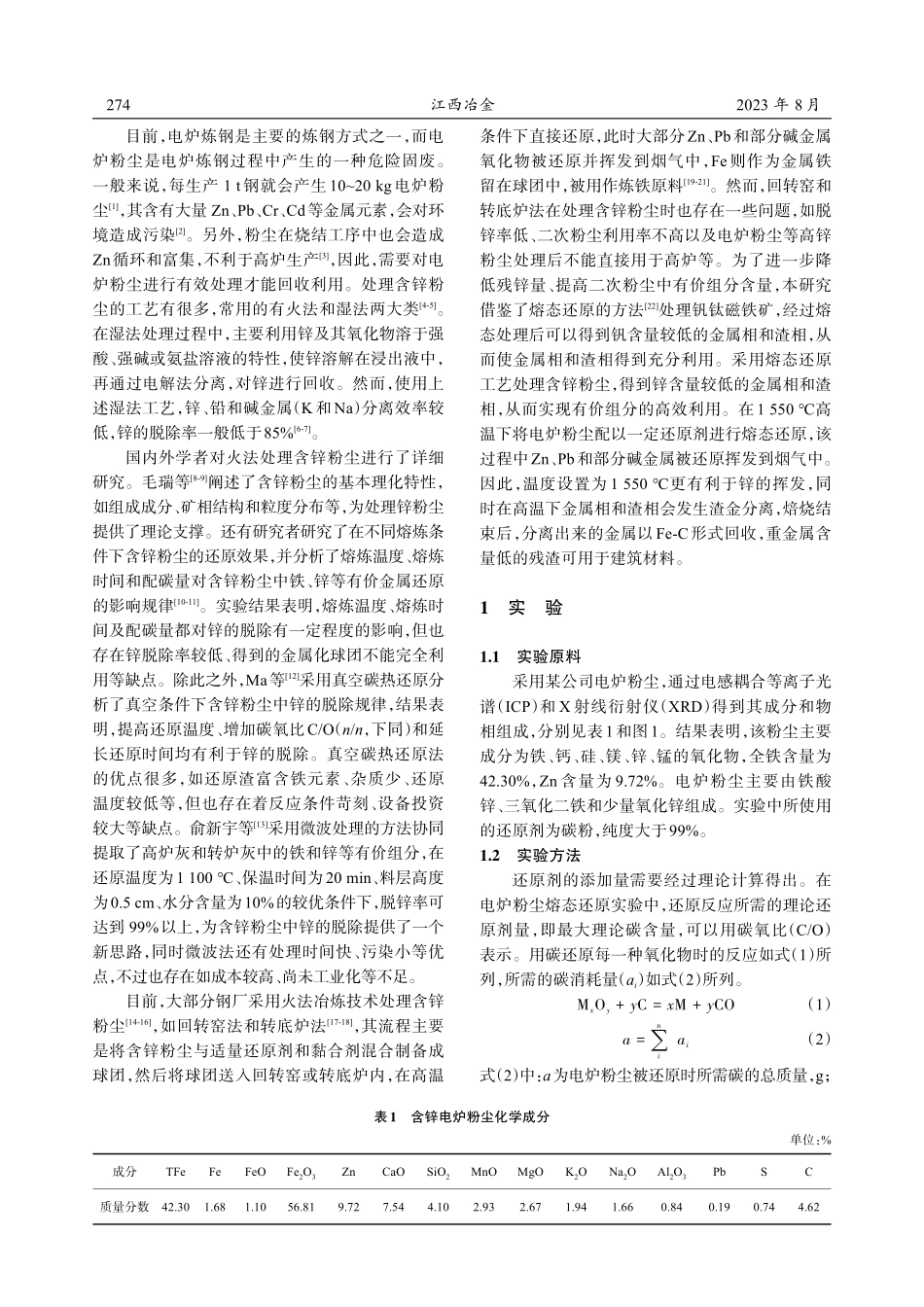

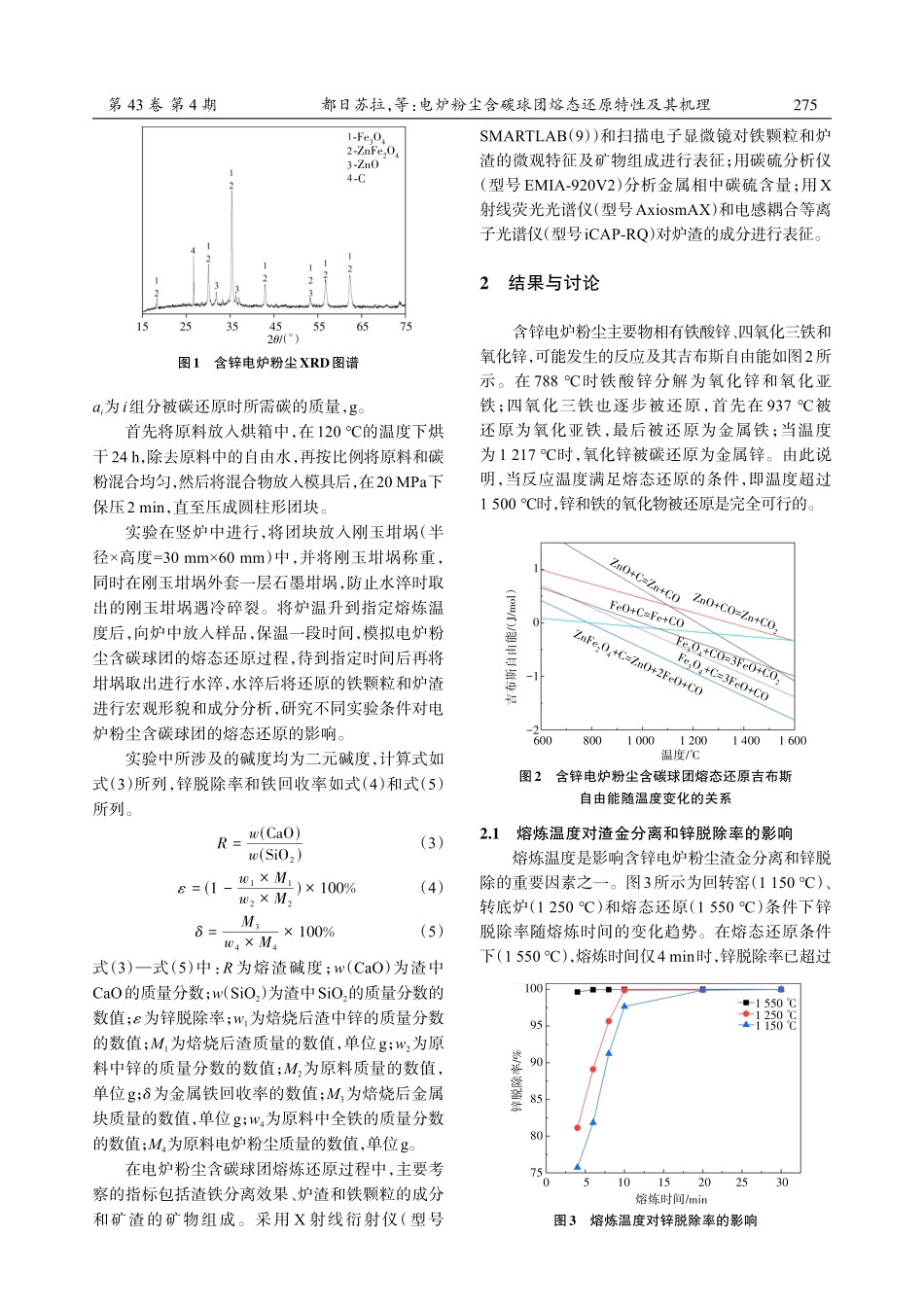

第43卷第4期2023年8月江西冶金JiangxiMetallurgyVol.43,No.4Aug.2023电炉粉尘含碳球团熔态还原特性及其机理都日苏拉,王哲,郭占成(北京科技大学钢铁冶金新技术国家重点实验室,北京100083)摘要:炼钢过程中产生的电炉粉尘属于有害固体废弃物,同时含有较多的铁、锌等有价元素。目前,钢厂处理电炉粉尘普遍存在脱锌率低、二次粉尘利用率不高等问题。对电炉粉尘含碳球团进行熔融还原实验,主要考察了熔炼温度,熔炼时间和熔渣成分对锌脱除率和渣金分离效果的影响。结果表明,提高熔炼温度、延长熔炼时间均有利于熔融过程中的锌的挥发和铁液滴的凝聚,从而促进渣金分离;熔渣碱度在1.2~1.8时,脱锌率变化趋势平稳,对渣金分离效果影响较小。根据实验结果确定了较优工艺参数:还原温度1550℃、碳氧比(C/O,摩尔比)为1.0、还原时间10~20min、熔渣碱度1.2,该条件下脱锌率可达99.9%以上,渣金两相分离完全。关键词:电炉粉尘;熔态还原;锌脱除率;渣金分离中图分类号:TF09文献标志码:AMeltingstatereductioncharacteristicsandmechanismofcarbon-containingpelletsfromelectricfurnacedustDurisula,WANGZhe,GUOZhancheng(StateKeyLaboratoryofAdvancedMetallurgy,UniversityofScienceandTechnologyBeijing,Beijing100083,China)Abstract:Electricfurnacedustfromironandsteelplantsisakindofharmfulsolidwasteandanimportantresourceforobtainingironandzincaswell.Atpresent,therestillexistsomeproblemsinthetreatingprocessofelectricfurnacedustinsteelplants,suchasthelowdezincificationratioofzincandinsufficientutilizationofsecondarydust.Inthispaper,smeltingreductiontechnologywasusedtosmeltcarbon-containingpelletsofelectricfurnacedust.Theroleofsmeltingtemperature,smeltingtimeandslagcompositiononthedezincificationratioandslag-metalseparationwasinvestigated.Theresultsshowthatincreasingsmeltingtemperatureandtimeisbeneficialtothevolatilizationofzincandthecondensationofirondropletsduringthemeltingprocess,thuspromotingtheseparationofslagandmetal.Thedezincificationratioisstablewhentheslagalkalinityis1.2to1.8,whichhaslittleinfluenceontheseparationeffectofslagandmetal.Theresultsalsoshowthattheoptimumprocessparameterswerereductiontemperatureof1550℃,theratioofcarbont...