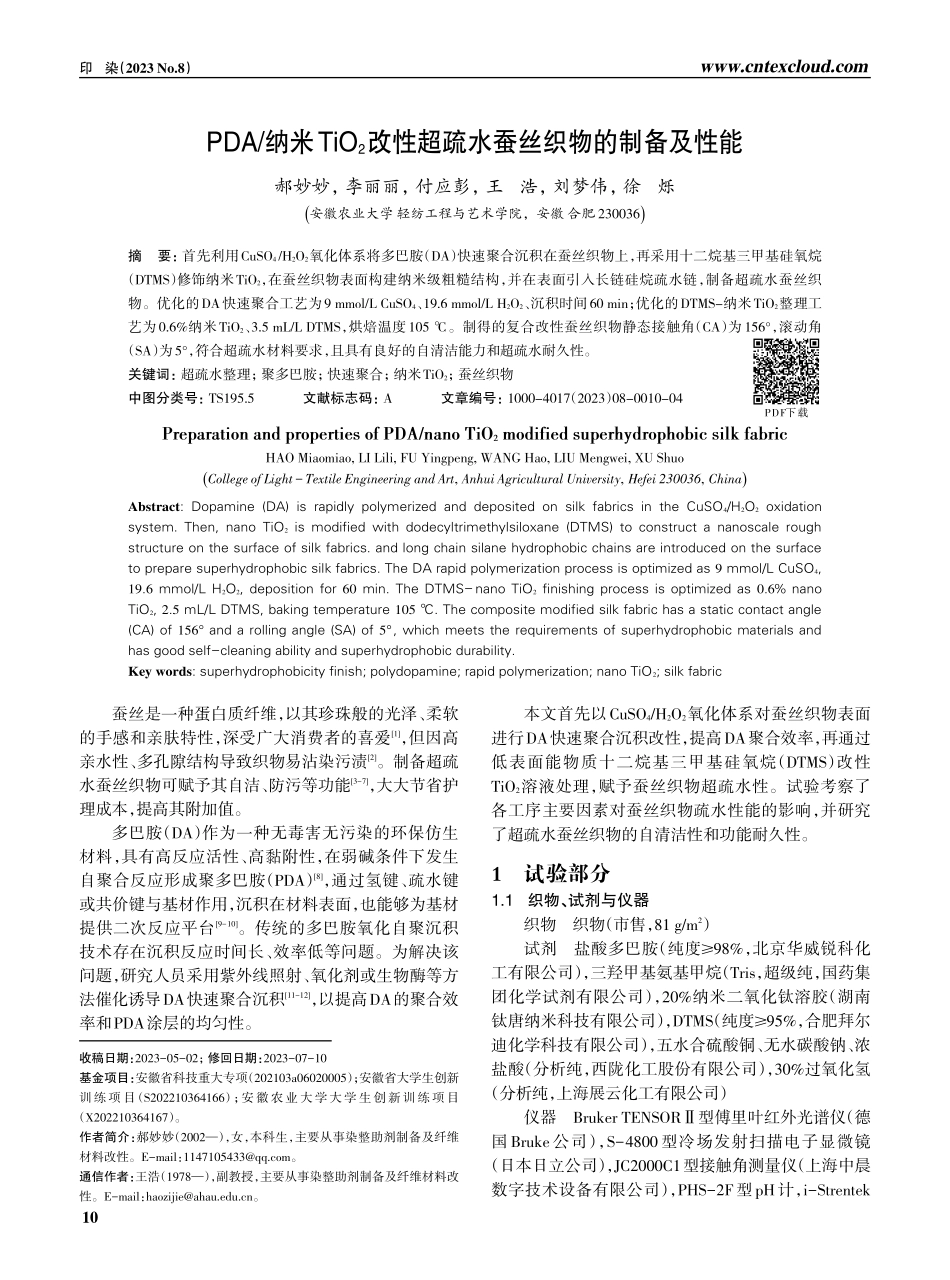

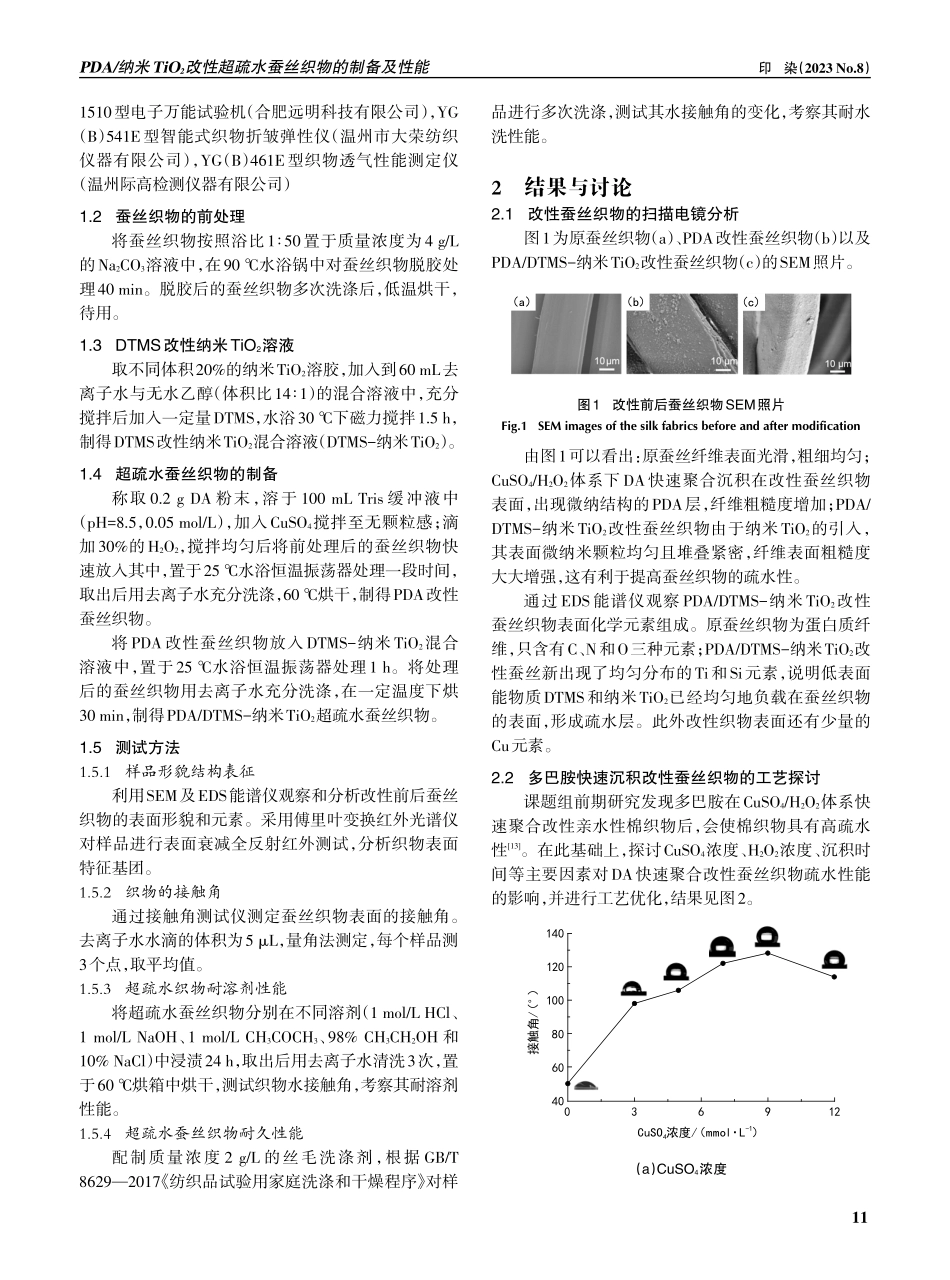

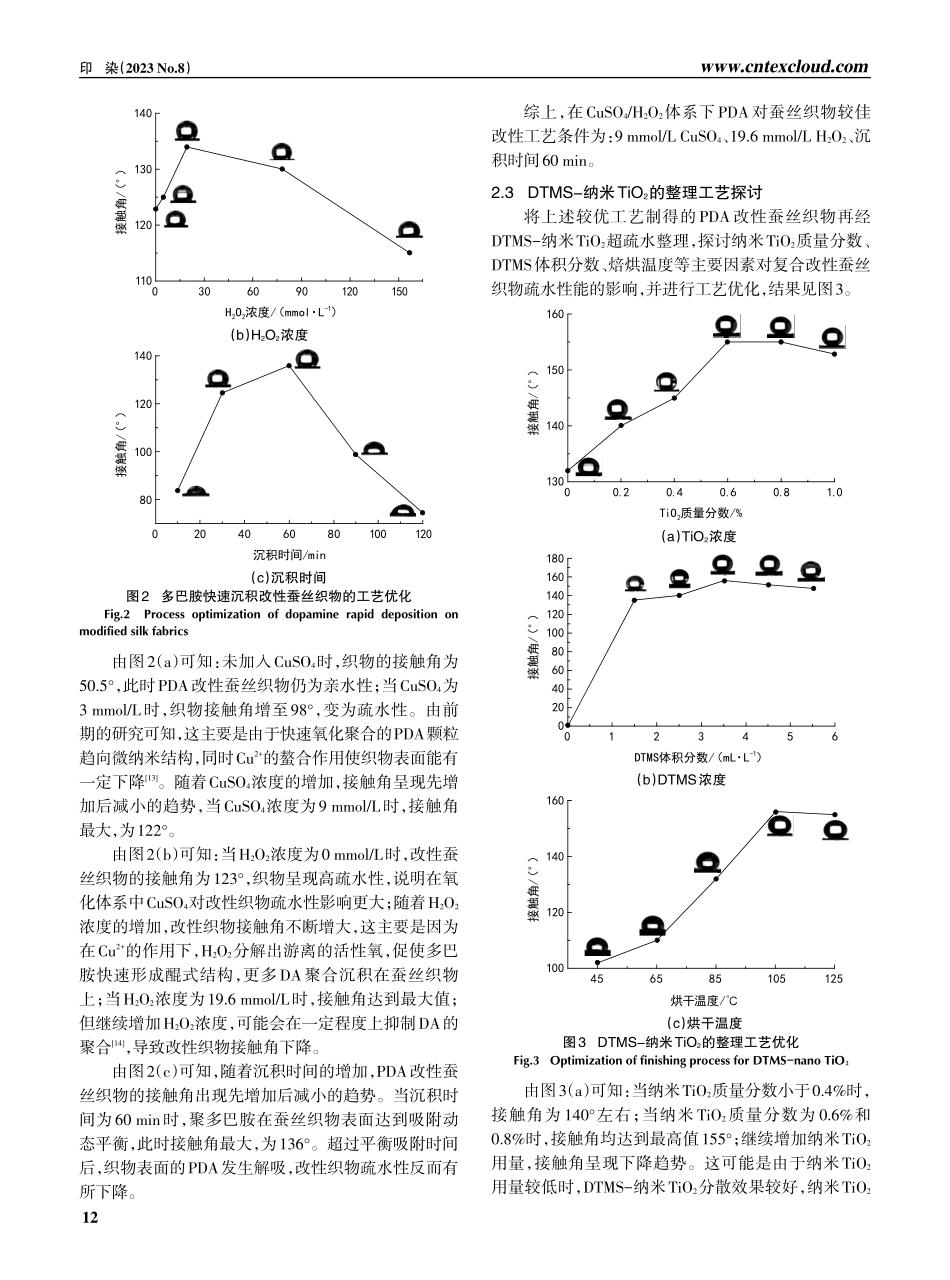

印染(2023No.8)www.cntexcloud.comPDA/纳米TiO2改性超疏水蚕丝织物的制备及性能郝妙妙,李丽丽,付应彭,王浩,刘梦伟,徐烁()安徽农业大学轻纺工程与艺术学院,安徽合肥230036摘要:首先利用CuSO4/H2O2氧化体系将多巴胺(DA)快速聚合沉积在蚕丝织物上,再采用十二烷基三甲基硅氧烷(DTMS)修饰纳米TiO2,在蚕丝织物表面构建纳米级粗糙结构,并在表面引入长链硅烷疏水链,制备超疏水蚕丝织物。优化的DA快速聚合工艺为9mmol/LCuSO4、19.6mmol/LH2O2、沉积时间60min;优化的DTMS-纳米TiO2整理工艺为0.6%纳米TiO2、3.5mL/LDTMS,烘焙温度105℃。制得的复合改性蚕丝织物静态接触角(CA)为156°,滚动角(SA)为5°,符合超疏水材料要求,且具有良好的自清洁能力和超疏水耐久性。关键词:超疏水整理;聚多巴胺;快速聚合;纳米TiO2;蚕丝织物中图分类号:TS195.5文献标志码:A文章编号:1000-4017(2023)08-0010-04PreparationandpropertiesofPDA/nanoTiO2modifiedsuperhydrophobicsilkfabricHAOMiaomiao,LILili,FUYingpeng,WANGHao,LIUMengwei,XUShuo()CollegeofLight-TextileEngineeringandArt,AnhuiAgriculturalUniversity,Hefei230036,ChinaAbstract:Dopamine(DA)israpidlypolymerizedanddepositedonsilkfabricsintheCuSO4/H2O2oxidationsystem.Then,nanoTiO2ismodifiedwithdodecyltrimethylsiloxane(DTMS)toconstructananoscaleroughstructureonthesurfaceofsilkfabrics.andlongchainsilanehydrophobicchainsareintroducedonthesurfacetopreparesuperhydrophobicsilkfabrics.TheDArapidpolymerizationprocessisoptimizedas9mmol/LCuSO4,19.6mmol/LH2O2,depositionfor60min.TheDTMS-nanoTiO2finishingprocessisoptimizedas0.6%nanoTiO2,2.5mL/LDTMS,bakingtemperature105℃.Thecompositemodifiedsilkfabrichasastaticcontactangle(CA)of156°andarollingangle(SA)of5°,whichmeetstherequirementsofsuperhydrophobicmaterialsandhasgoodself-cleaningabilityandsuperhydrophobicdurability.Keywords:superhydrophobicityfinish;polydopamine;rapidpolymerization;nanoTiO2;silkfabric蚕丝是一种蛋白质纤维,以其珍珠般的光泽、柔软的手感和亲肤特性,深受广大消费者的喜爱[1],但因高亲水性、多孔隙结构导致织物易沾染污渍[2]。制备超疏水蚕丝织物可赋予其自洁、防污等功能[3-7],大大节省护理成本,提高其附加值。多巴胺(DA)作为一种无毒害...