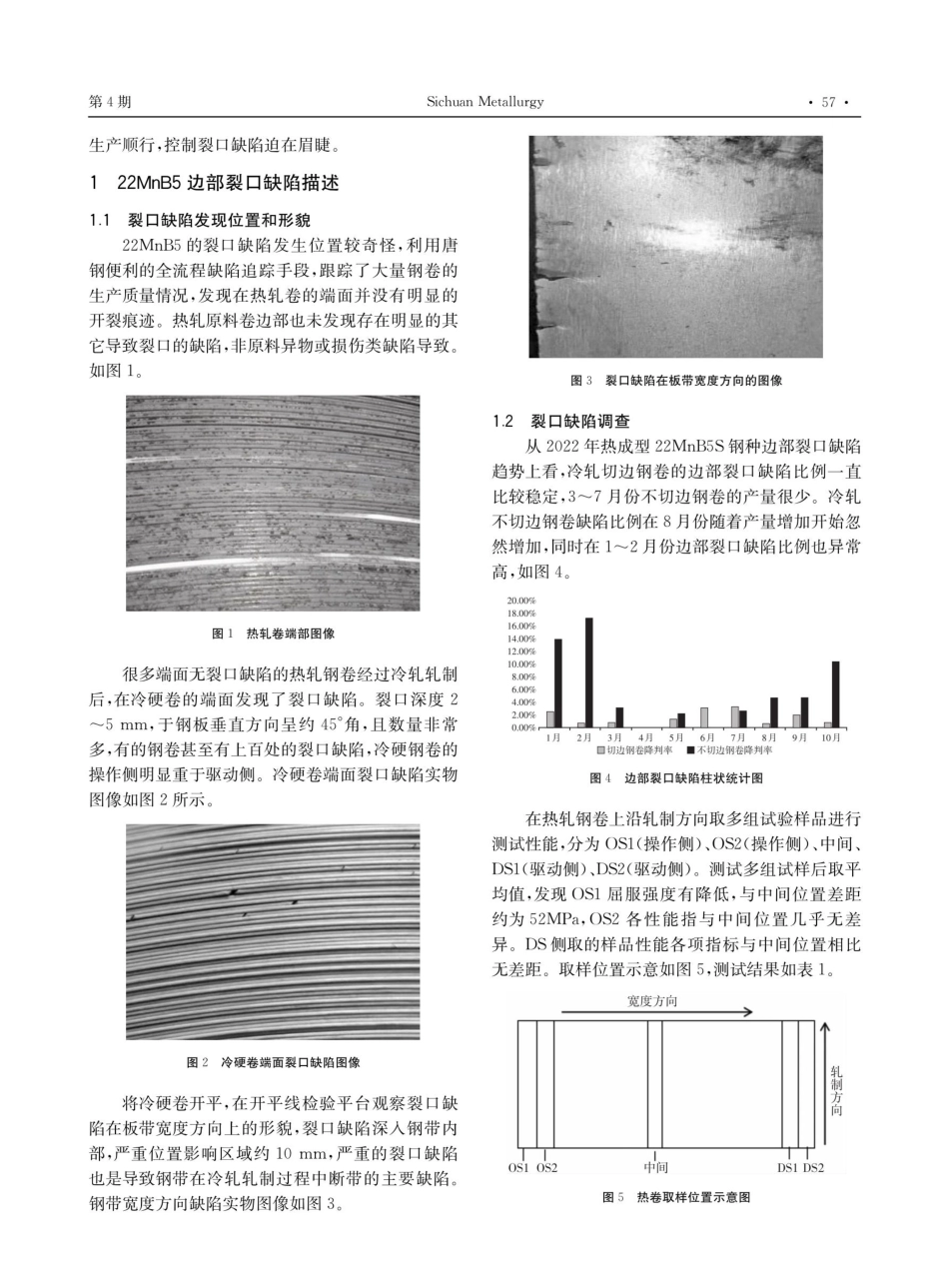

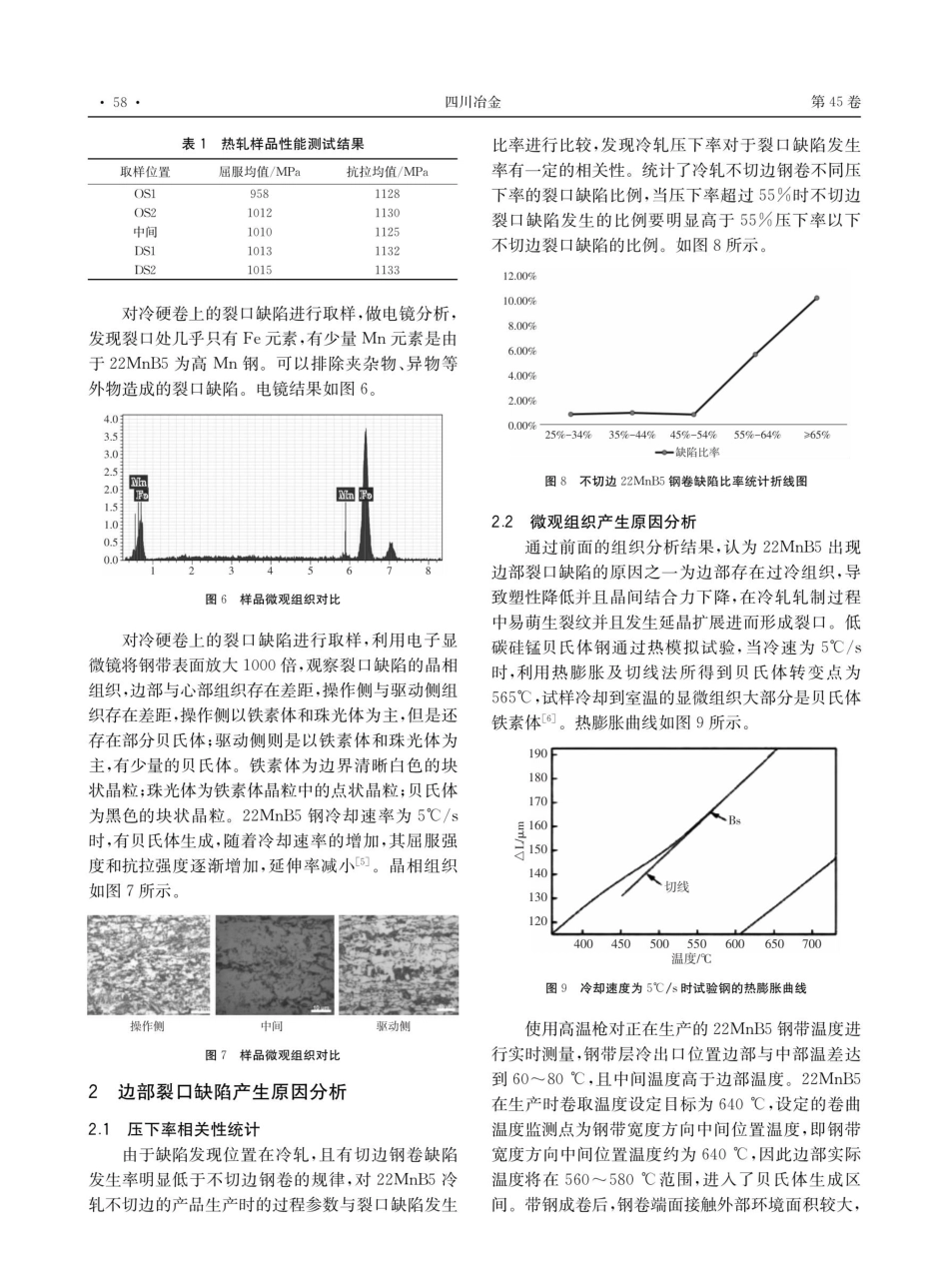

第45卷第4期2023年8月四川冶金SichuanMetallurgyVol.45No.4Aug.,2023文章编号:1001—5108(2023)04—0056—0522MnB5冷轧边部裂口缺陷分析及控制白玉朋,张帅,史建伟,王占国,栗建辉(唐山钢铁集团有限责任公司质量管理部,河北唐山063000)摘要:文章对22MnB5钢种冷轧边部裂口缺陷的宏观形貌及特殊特性进行了详细描述。利用电子显微镜观察分析了缺陷的微观组织,钢带裂口较多的一侧充斥着大量的贝氏体;边部的晶相组织与钢带中间位置有很大的区别,推断出导致裂口产生的根本原因是钢带宽度方向上组织不均,组织不均导致在冷轧加工过程中钢带受力不均,从而使钢带边部撕裂,产生边部裂口缺陷。利用便利的信息化条件对冷、热轧的生产过程进行了还原,通过数据收集和分析找出缺陷产生的可能原因。再通过生产试验对冷轧压下率进行了调整,对热轧层冷冷却过程包括层冷水温度、超快冷喷嘴等进行了综合调整。经过冷轧、热轧联动调整后,大大降低了缺陷发生的概率,保证了冷轧产线生产过程的稳定。关键词:22MnB5;组织均匀性;贝氏体;层冷冷却;压下率;边部裂口中图分类号:TG335.5Analysisandcontrolofedgecrackdefectsin22MnB5coldrollingBAIYupeng,ZHANGShuai,SHIJianwei,WANGZhanguo,LIJianhui(TangshanIronandSteelGroupCo.LTD,Tangshan063000,Hebei,China)Abstract:Thearticleprovidesadetaileddescriptionofthemacroscopicmorphologyandspecialcharacteristicsofcoldrollededgecrackdefectsin22MnB5steel.Themicrostructureofdefectswasobservedandanalyzedbyelectronmi-croscope.Thesidewithmorecracksinthesteelstripwasfilledwithalargeamountofbainite;Thereisasignificantdifferencebetweenthecrystalphasestructureattheedgesandthemiddlepositionofthesteelstrip.Itisinferredthatthefundamentalreasonfortheoccurrenceofcracksistheunevenstructureinthewidthdirectionofthesteelstrip,whichleadstounevenstressonthesteelstripduringcoldrollingprocessing,resultinginedgetearingandedgecrackdefects.Utilizingconvenientinformationtechnology,theproductionprocessesofcoldandhotrollingwererestored,andpossiblecausesofdefectswereidentifiedthroughdatacollectionandanalysis.Furtheradjust-mentsweremadetothecoldrollingreductionratethroughproductionexperiments,andcomprehensiveadjustmentsweremadetothecoldrollinglayerc...