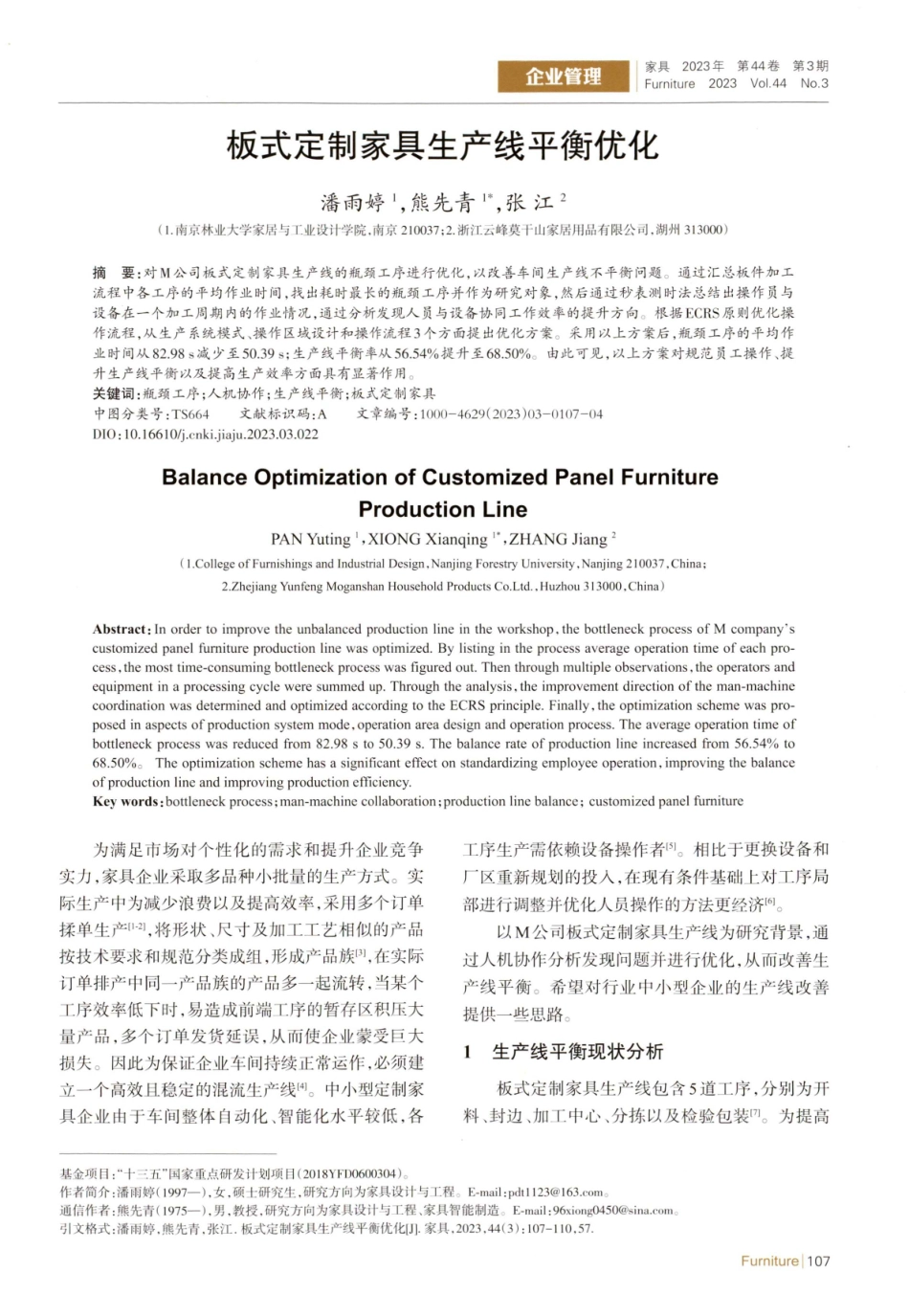

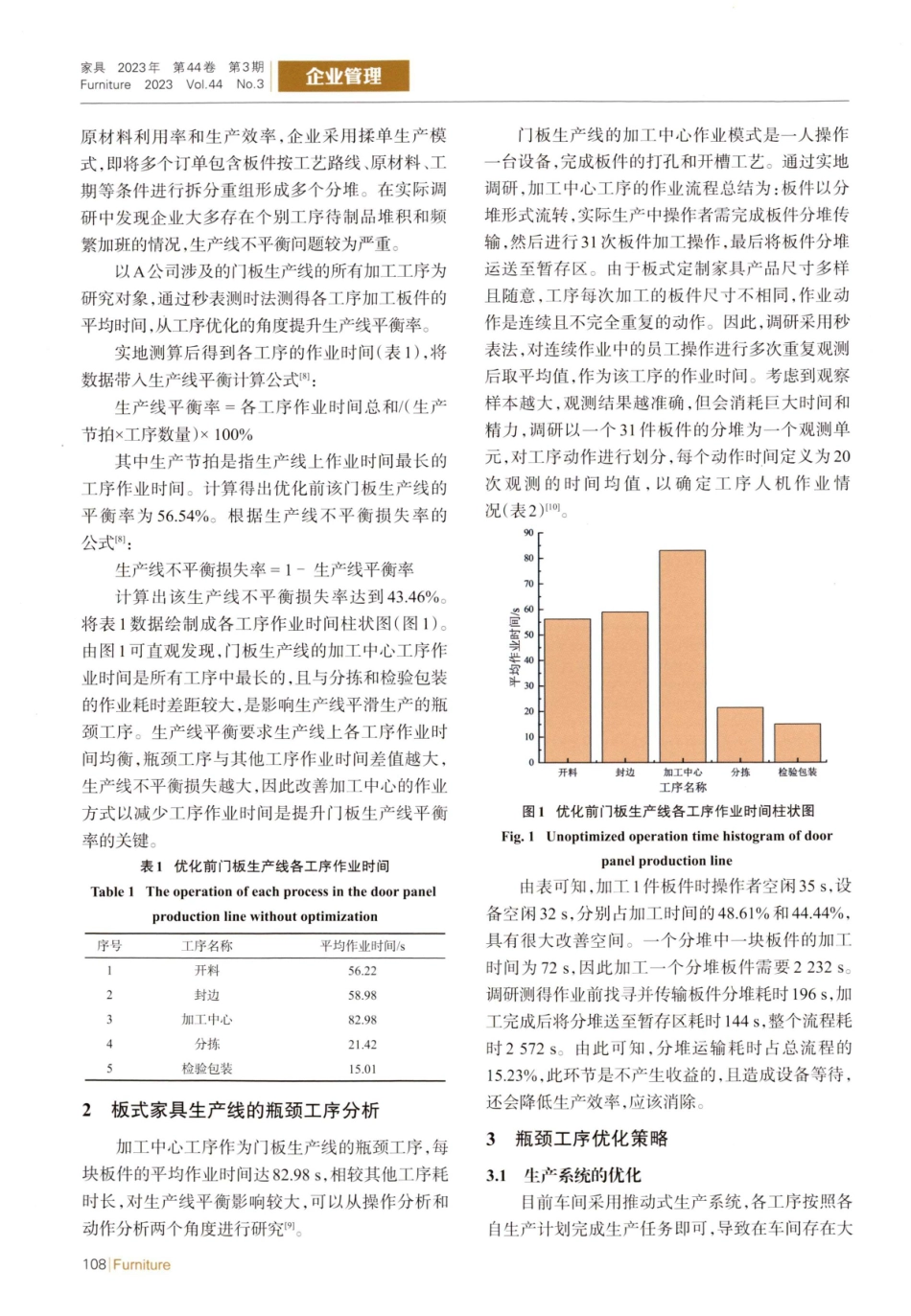

Furniture107企业管理家具2023年第44卷第3期Furniture2023Vol.44No.3第44卷第3期板式定制家具生产线平衡优化潘雨婷1,熊先青1,张江?(1.南京林业大学家居与工业设计学院,南京210037;2.浙江云峰莫干山家居用品有限公司,湖州313000)摘要:对M公司板式定制家具生产线的瓶颈工序进行优化,以改善车间生产线不平衡问题。通过汇总板件加工流程中各工序的平均作业时间,找出耗时最长的瓶颈工序并作为研究对象,然后通过秒表测时法总结出操作员与设备在一个加工周期内的作业情况,通过分析发现人员与设备协同工作效率的提升方向。根据ECRS原则优化操作流程,从生产系统模式、操作区域设计和操作流程3个方面提出优化方案。采用以上方案后,瓶颈工序的平均作业时间从82.98s减少至50.39s;生产线平衡率从56.54%提升至68.50%。由此可见,以上方案对规范员工操作、提升生产线平衡以及提高生产效率方面具有显著作用。关键词:瓶颈工序;人机协作;生产线平衡;板式定制家具中图分类号:TS664文献标识码:A文章编号:1000-4629(2023)03-0107-04DI10:10.16610/j.cnki.jiaju.2023.03.022BalanceOptimizationofCustomizedPanelFurnitureProductionLinePANYuting',XIONGXianqing*,ZHANGJiang(1.CollegeofFurnishingsandIndustrialDesign,NanjingForestryUniversity,Nanjing210037,China;2.ZhejiangYunfengMoganshanHouseholdProductsCo.Ltd.,Huzhou313000,China)Abstract:Inordertoimprovetheunbalancedproductionlineintheworkshop,thebottleneckprocessofMcompany'scustomizedpanelfurnitureproductionlinewasoptimized.Bylistingintheprocessaverageoperationtimeofeachpro-cess,themosttime-consumingbottleneckprocesswasfiguredout.Thenthroughmultipleobservations,theoperatorsandequipmentinaprocessingcycleweresummedup.Throughtheanalysis,theimprovementdirectionoftheman-machinecoordinationwasdeterminedandoptimizedaccordingtotheECRSprinciple.Finally,theoptimizationschemewaspro-posedinaspectsofproductionsystemmode,operationareadesignandoperationprocess.Theaverageoperationtimeofbottleneckprocesswasreducedfrom82.98sto50.39s.Thebalancerateofproductionlineincreasedfrom56.54%to68.50%。Theoptimizationschemehasasignificanteffectonstandardizingemployeeoperation,improvingthebalanceofproductionlineandimprovingproduc...