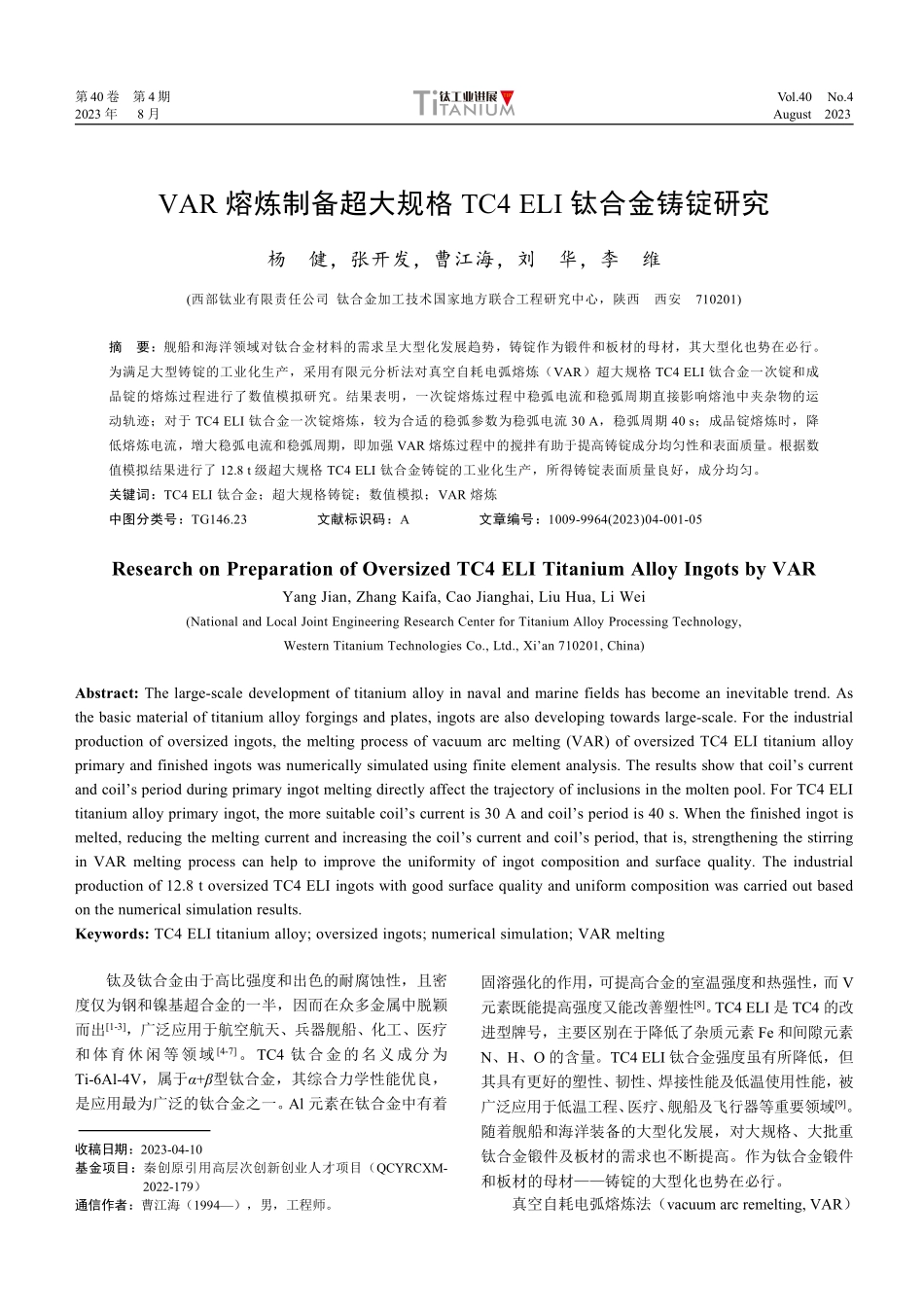

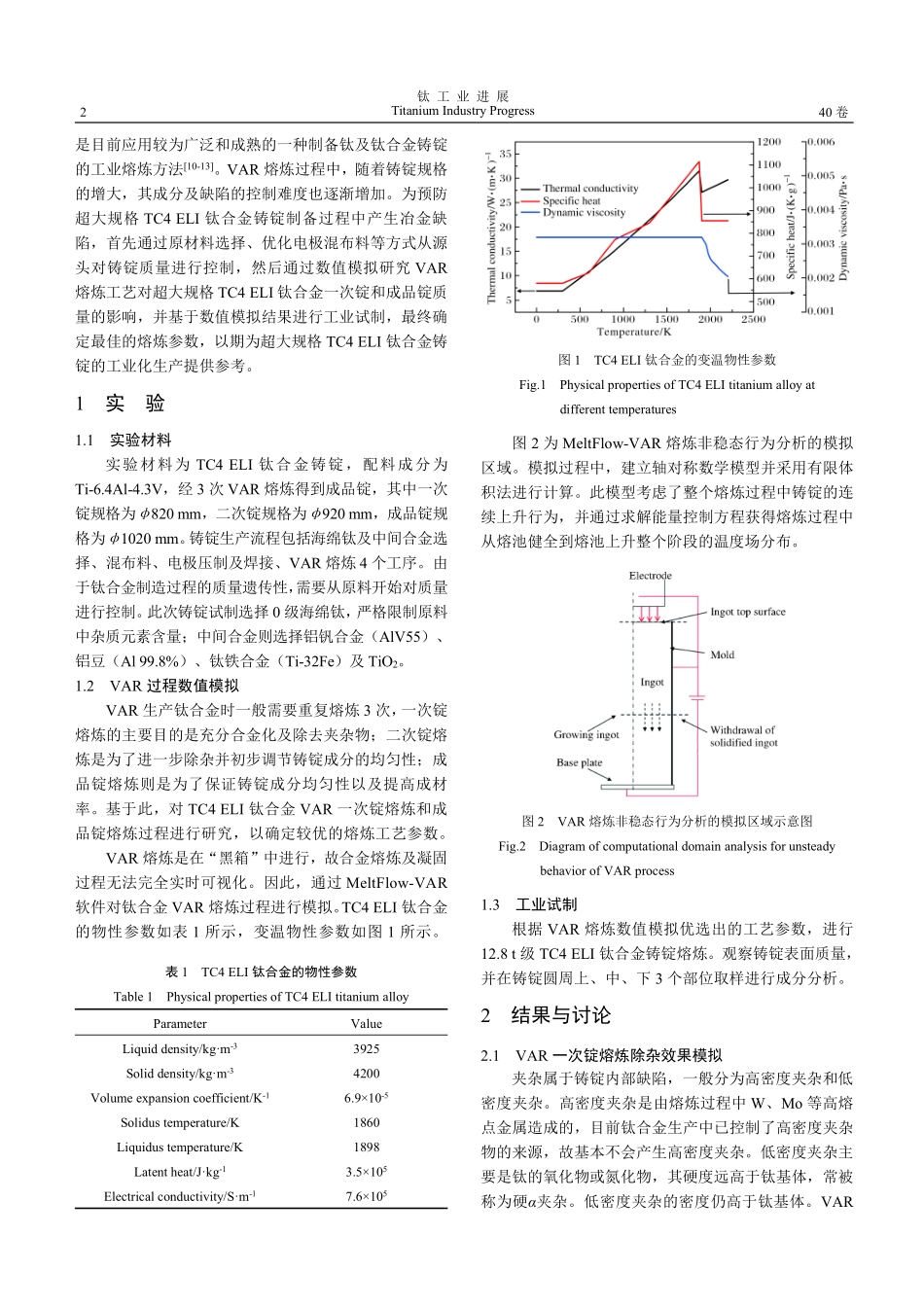

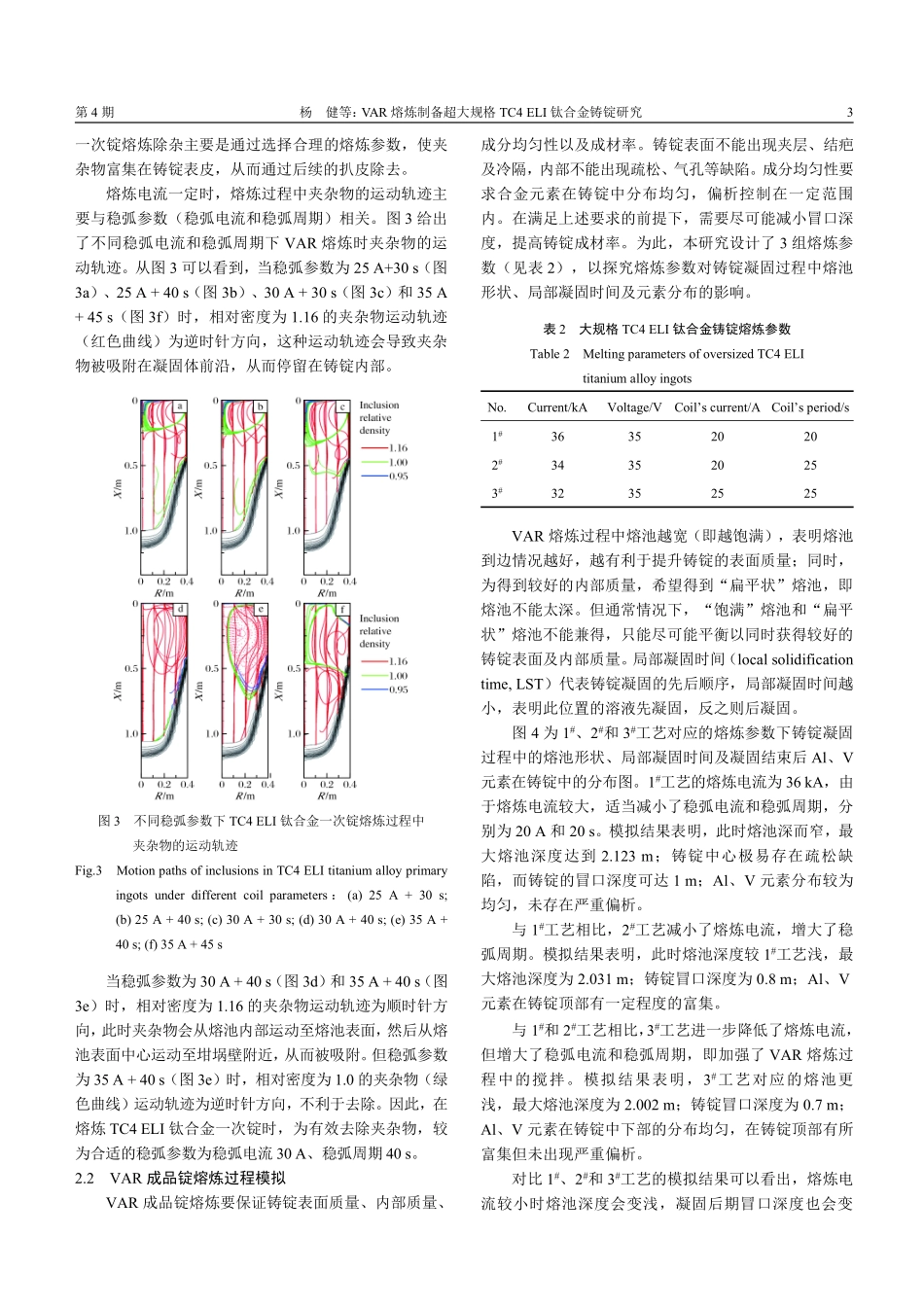

第40卷第4期Vol.40No.42023年8月August2023VAR熔炼制备超大规格TC4ELI钛合金铸锭研究杨健,张开发,曹江海,刘华,李维(西部钛业有限责任公司钛合金加工技术国家地方联合工程研究中心,陕西西安710201)摘要:舰船和海洋领域对钛合金材料的需求呈大型化发展趋势,铸锭作为锻件和板材的母材,其大型化也势在必行。为满足大型铸锭的工业化生产,采用有限元分析法对真空自耗电弧熔炼(VAR)超大规格TC4ELI钛合金一次锭和成品锭的熔炼过程进行了数值模拟研究。结果表明,一次锭熔炼过程中稳弧电流和稳弧周期直接影响熔池中夹杂物的运动轨迹;对于TC4ELI钛合金一次锭熔炼,较为合适的稳弧参数为稳弧电流30A,稳弧周期40s;成品锭熔炼时,降低熔炼电流,增大稳弧电流和稳弧周期,即加强VAR熔炼过程中的搅拌有助于提高铸锭成分均匀性和表面质量。根据数值模拟结果进行了12.8t级超大规格TC4ELI钛合金铸锭的工业化生产,所得铸锭表面质量良好,成分均匀。关键词:TC4ELI钛合金;超大规格铸锭;数值模拟;VAR熔炼中图分类号:TG146.23文献标识码:A文章编号:1009-9964(2023)04-001-05ResearchonPreparationofOversizedTC4ELITitaniumAlloyIngotsbyVARYangJian,ZhangKaifa,CaoJianghai,LiuHua,LiWei(NationalandLocalJointEngineeringResearchCenterforTitaniumAlloyProcessingTechnology,WesternTitaniumTechnologiesCo.,Ltd.,Xi’an710201,China)Abstract:Thelarge-scaledevelopmentoftitaniumalloyinnavalandmarinefieldshasbecomeaninevitabletrend.Asthebasicmaterialoftitaniumalloyforgingsandplates,ingotsarealsodevelopingtowardslarge-scale.Fortheindustrialproductionofoversizedingots,themeltingprocessofvacuumarcmelting(VAR)ofoversizedTC4ELItitaniumalloyprimaryandfinishedingotswasnumericallysimulatedusingfiniteelementanalysis.Theresultsshowthatcoil’scurrentandcoil’speriodduringprimaryingotmeltingdirectlyaffectthetrajectoryofinclusionsinthemoltenpool.ForTC4ELItitaniumalloyprimaryingot,themoresuitablecoil’scurrentis30Aandcoil’speriodis40s.Whenthefinishedingotismelted,reducingthemeltingcurrentandincreasingthecoil’scurrentandcoil’speriod,thatis,strengtheningthestirringinVARmeltingprocesscanhelptoimprovetheuniformityofingotcompositionandsurfacequality.Theindustrialproductionof12.8tover...