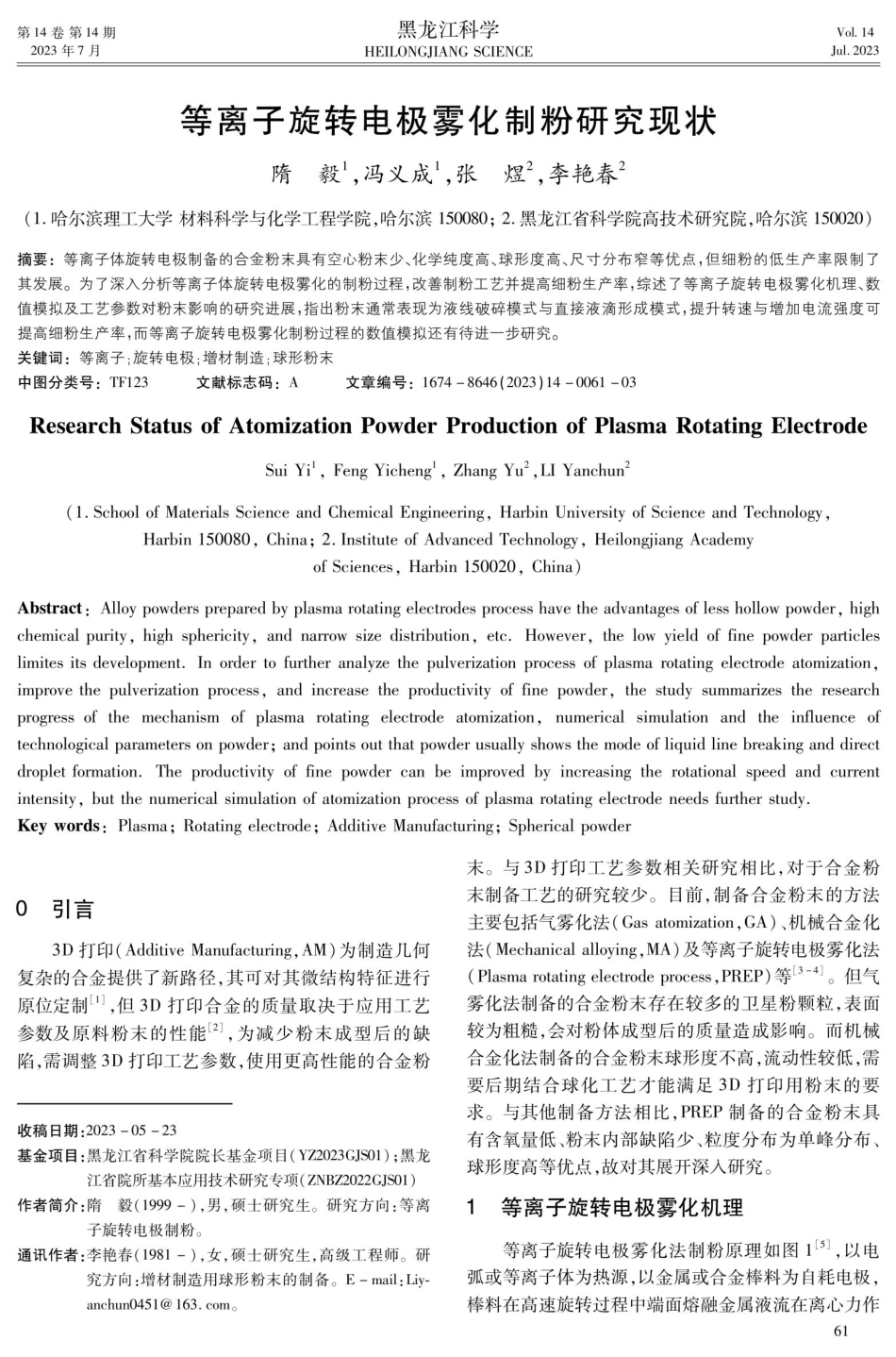

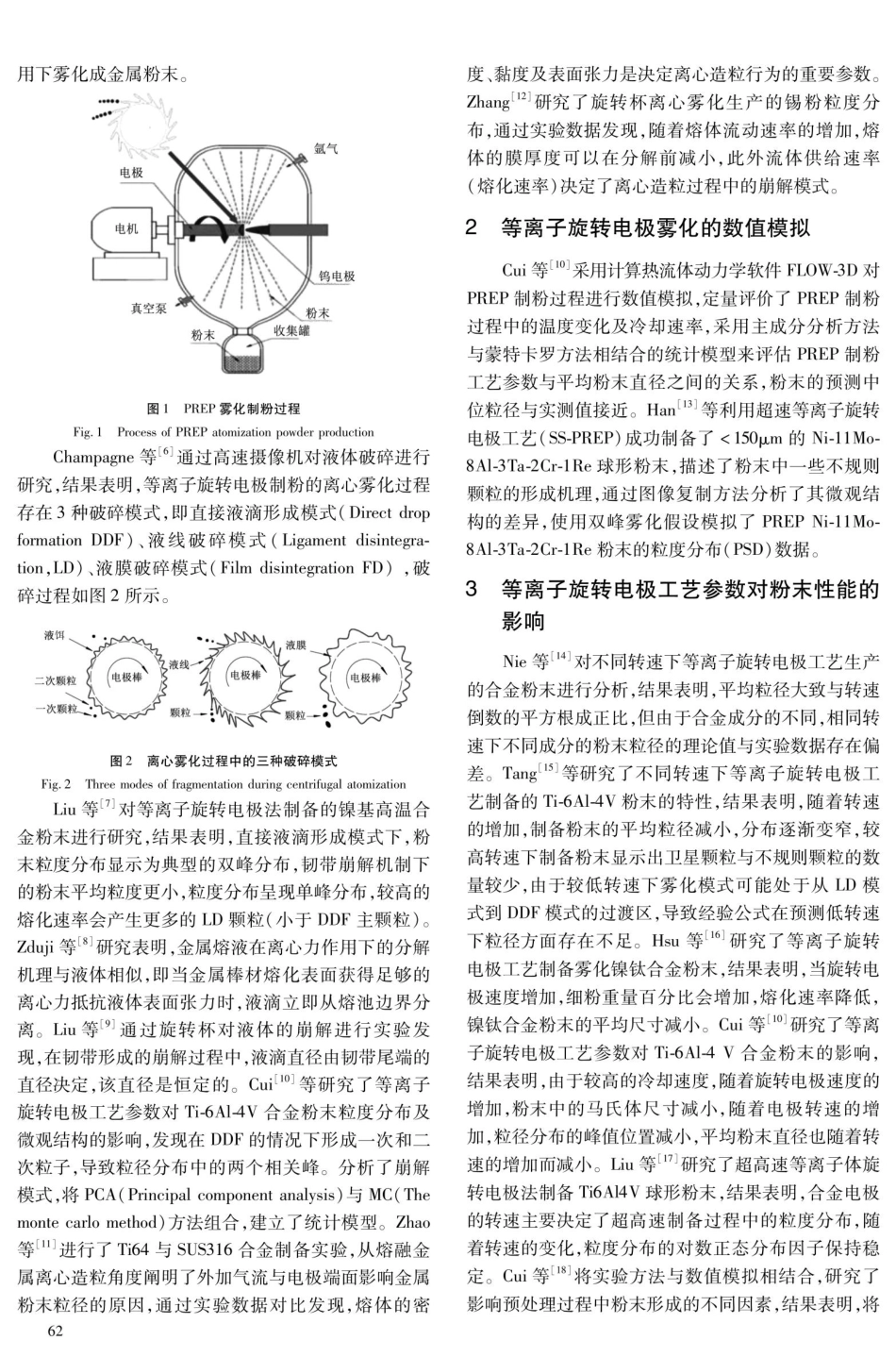

第14卷第14期2023年7月黑龙江科学HEILONGJIANGSCIENCEVol.14Jul.2023等离子旋转电极雾化制粉研究现状末。与3D打印工艺参数相关研究相比,对于合金粉隋毅',冯义成,张煜?,李艳春?(1.哈尔滨理工大学材料科学与化学工程学院,哈尔滨150080;2.黑龙江省科学院高技术研究院,哈尔滨150020)摘要:等离子体旋转电极制备的合金粉末具有空心粉末少、化学纯度高、球形度高、尺寸分布窄等优点,但细粉的低生产率限制了其发展。为了深入分析等离子体旋转电极雾化的制粉过程,改善制粉工艺并提高细粉生产率,综述了等离子旋转电极雾化机理、数值模拟及工艺参数对粉末影响的研究进展,指出粉末通常表现为液线破碎模式与直接液滴形成模式,提升转速与增加电流强度可提高细粉生产率,而等离子旋转电极雾化制粉过程的数值模拟还有待进一步研究。关键词:等离子,旋转电极;增材制造;球形粉末中图分类号:TF123ResearchStatusofAtomizationPowderProductionofPlasmaRotatingElectrode(1.SchoolofMaterialsScienceandChemicalEngineering,HarbinUniversityofScienceandTechnology,Abstract:Alloypowderspreparedbyplasmarotatingelectrodesprocesshavetheadvantagesoflesshollowpowder,highchemicalpurity,highsphericity,andnarrowsizedistribution,etc.However,thelowyieldoffinepowderparticleslimitesitsdevelopment.Inordertofurtheranalyzethepulverizationprocessofplasmarotatingelectrodeatomization,improvethepulverizationprocess,andincreasetheproductivityoffinepowder,thestudysummarizestheresearchprogressofthemechanismofplasmarotatingelectrodeatomization,numericalsimulationandtheinfluenceoftechnologicalparametersonpowder;andpointsoutthatpowderusuallyshowsthemodeofliquidlinebreakinganddirectdropletformation.Theproductivityoffinepowdercanbeimprovedbyincreasingtherotationalspeedandcurrentintensity,butthenumericalsimulationofatomizationprocessofplasmarotatingelectrodeneedsfurtherstudy.Keywords:Plasma;Rotatingelectrode;AdditiveManufacturing;Sphericalpowder0引言3D打印(AdditiveManufacturing,AM)为制造几何复杂的合金提供了新路径,其可对其微结构特征进行原位定制["],但3D打印合金的质量取决于应用工艺参数及原料粉末的性能[2],为减少粉末成型后的缺陷,需调整3D打印工艺参数,使用更高性能的合金粉收...