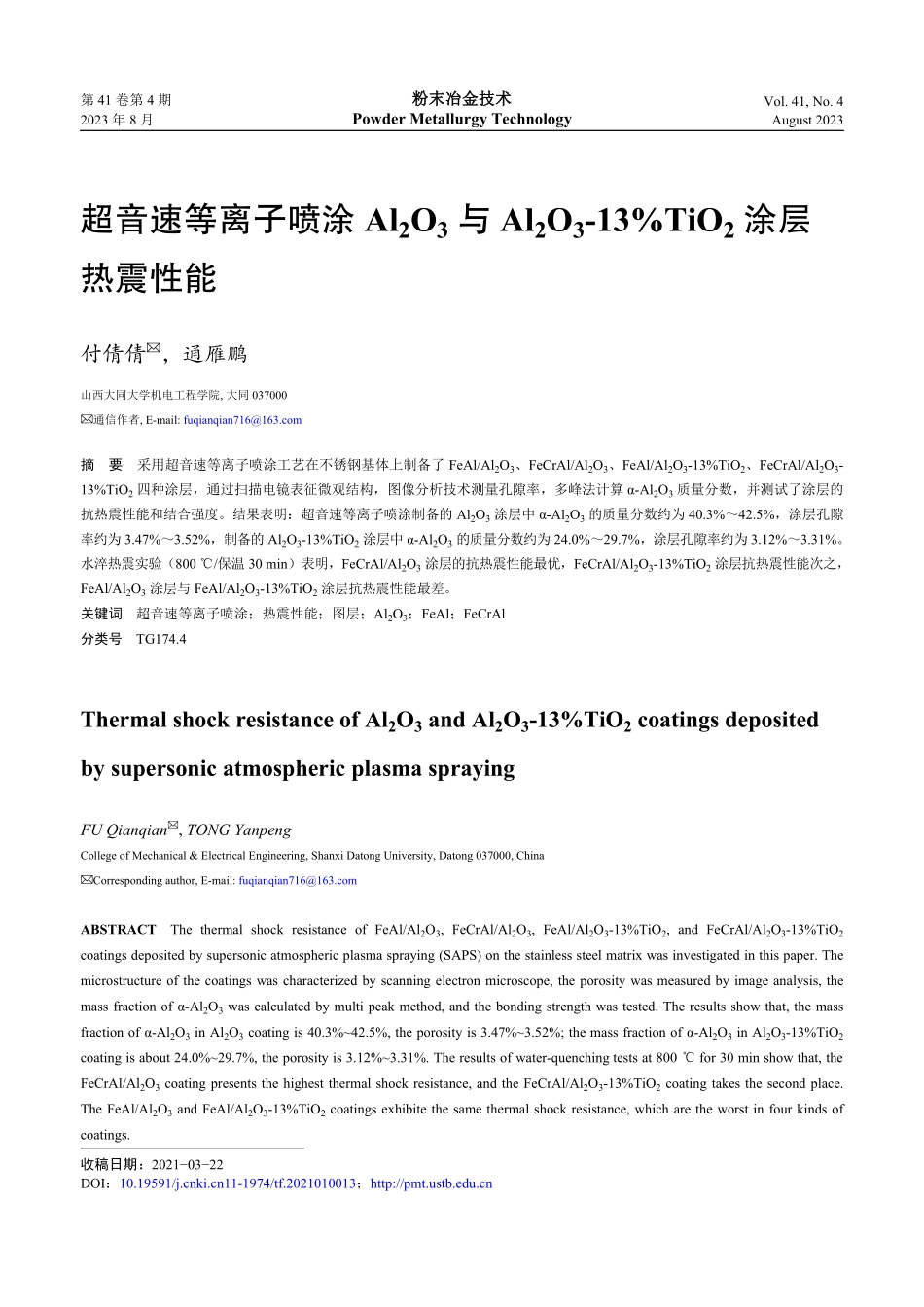

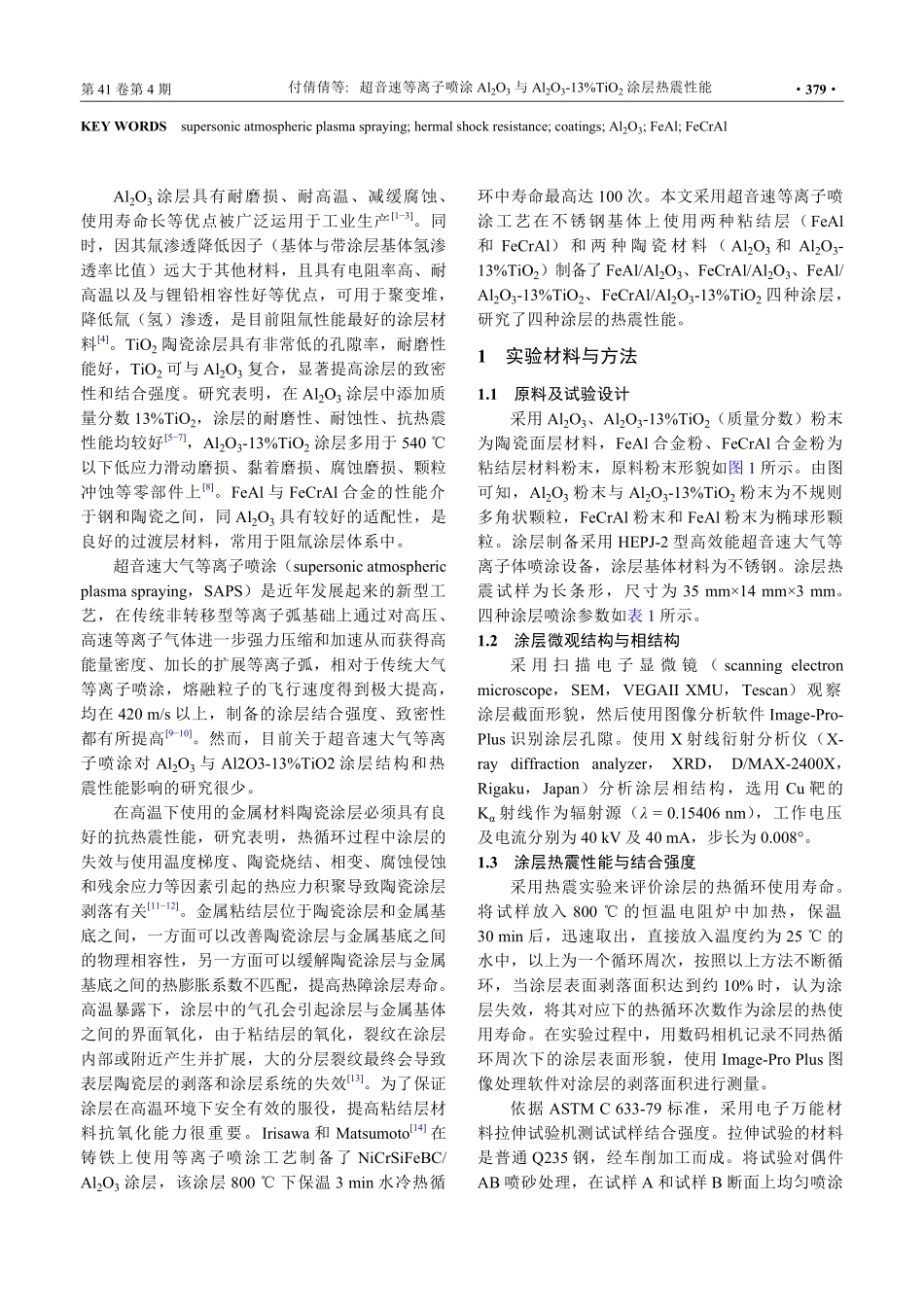

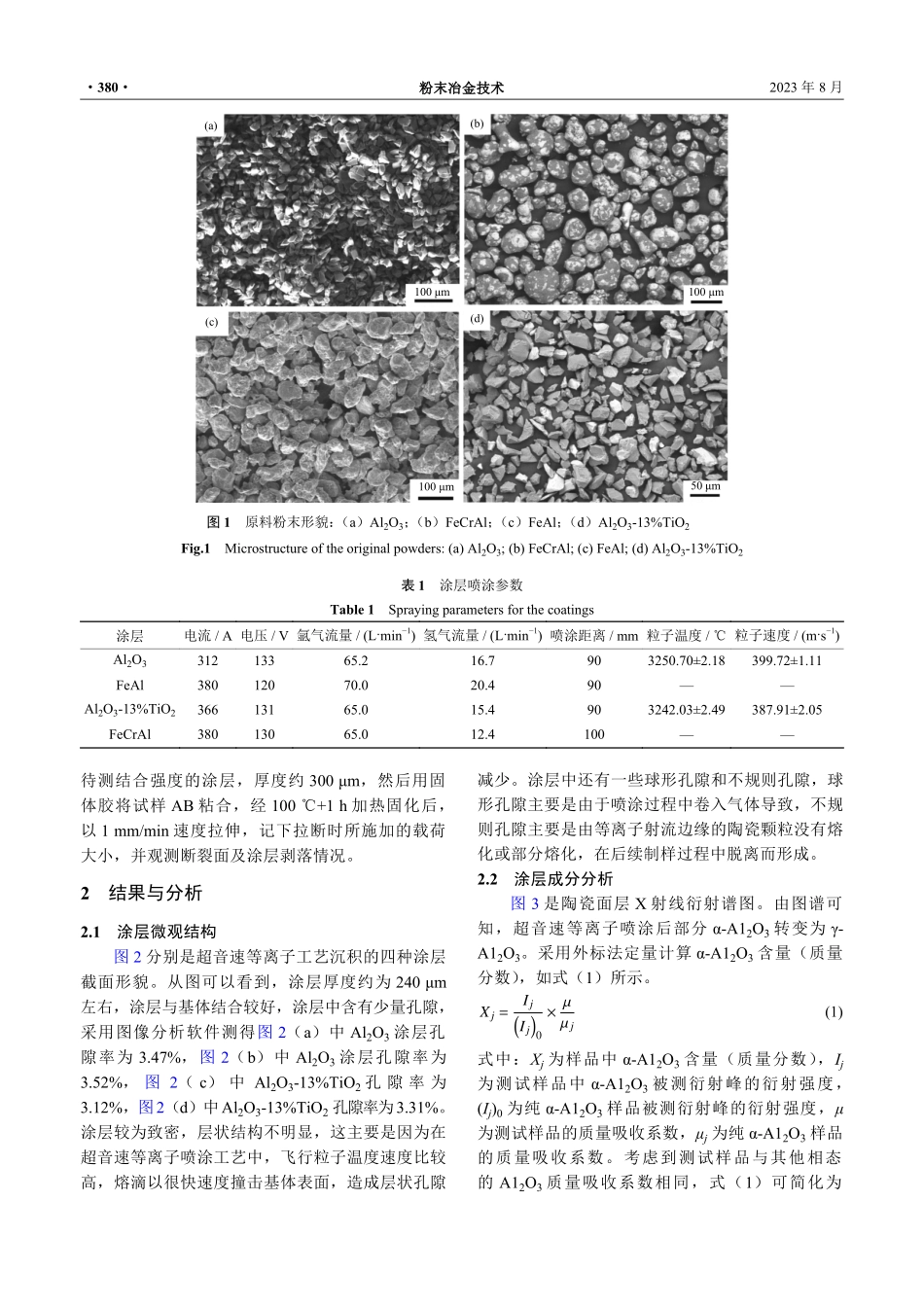

超音速等离子喷涂Al2O3与Al2O3-13%TiO2涂层热震性能付倩倩✉,通雁鹏山西大同大学机电工程学院,大同037000✉通信作者,E-mail:fuqianqian716@163.com摘要采用超音速等离子喷涂工艺在不锈钢基体上制备了FeAl/Al2O3、FeCrAl/Al2O3、FeAl/Al2O3-13%TiO2、FeCrAl/Al2O3-13%TiO2四种涂层,通过扫描电镜表征微观结构,图像分析技术测量孔隙率,多峰法计算α-Al2O3质量分数,并测试了涂层的抗热震性能和结合强度。结果表明:超音速等离子喷涂制备的Al2O3涂层中α-Al2O3的质量分数约为40.3%~42.5%,涂层孔隙率约为3.47%~3.52%,制备的Al2O3-13%TiO2涂层中α-Al2O3的质量分数约为24.0%~29.7%,涂层孔隙率约为3.12%~3.31%。水淬热震实验(800℃/保温30min)表明,FeCrAl/Al2O3涂层的抗热震性能最优,FeCrAl/Al2O3-13%TiO2涂层抗热震性能次之,FeAl/Al2O3涂层与FeAl/Al2O3-13%TiO2涂层抗热震性能最差。关键词超音速等离子喷涂;热震性能;图层;Al2O3;FeAl;FeCrAl分类号TG174.4ThermalshockresistanceofAl2O3andAl2O3-13%TiO2coatingsdepositedbysupersonicatmosphericplasmasprayingFUQianqian✉,TONGYanpengCollegeofMechanical&ElectricalEngineering,ShanxiDatongUniversity,Datong037000,China✉Correspondingauthor,E-mail:fuqianqian716@163.comABSTRACTThethermalshockresistanceofFeAl/Al2O3,FeCrAl/Al2O3,FeAl/Al2O3-13%TiO2,andFeCrAl/Al2O3-13%TiO2coatingsdepositedbysupersonicatmosphericplasmaspraying(SAPS)onthestainlesssteelmatrixwasinvestigatedinthispaper.Themicrostructureofthecoatingswascharacterizedbyscanningelectronmicroscope,theporositywasmeasuredbyimageanalysis,themassfractionofα-Al2O3wascalculatedbymultipeakmethod,andthebondingstrengthwastested.Theresultsshowthat,themassfractionofα-Al2O3inAl2O3coatingis40.3%~42.5%,theporosityis3.47%~3.52%;themassfractionofα-Al2O3inAl2O3-13%TiO2coatingisabout24.0%~29.7%,theporosityis3.12%~3.31%.Theresultsofwater-quenchingtestsat800℃for30minshowthat,theFeCrAl/Al2O3coatingpresentsthehighestthermalshockresistance,andtheFeCrAl/Al2O3-13%TiO2coatingtakesthesecondplace.TheFeAl/Al2O3andFeAl/Al2O3-13%TiO2coatingsexhibitethesamethermalshockresistance,whicharetheworstinfourkindsofcoatings.收稿日期:2021−03−22DOI:10.19591/j.cnk...