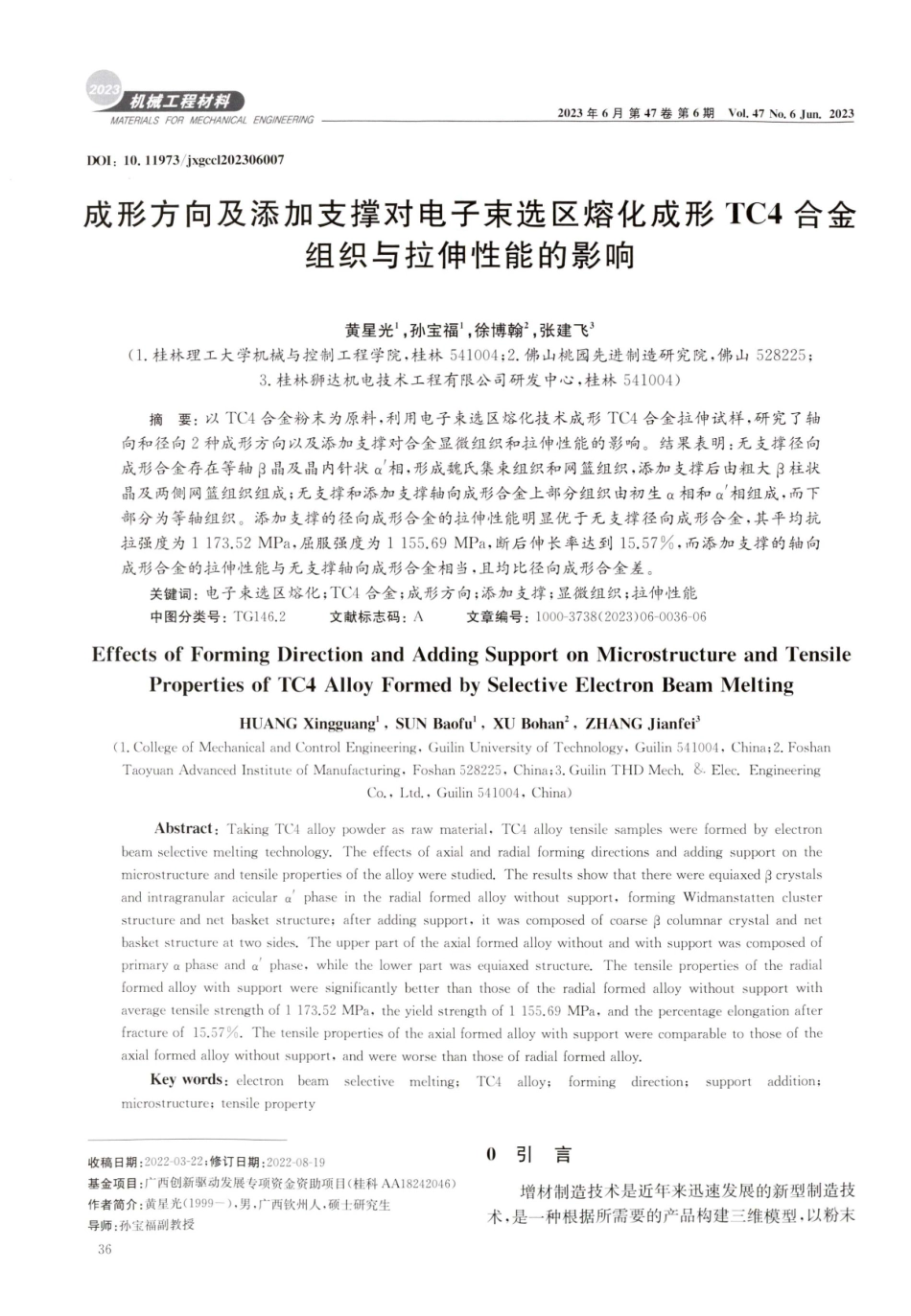

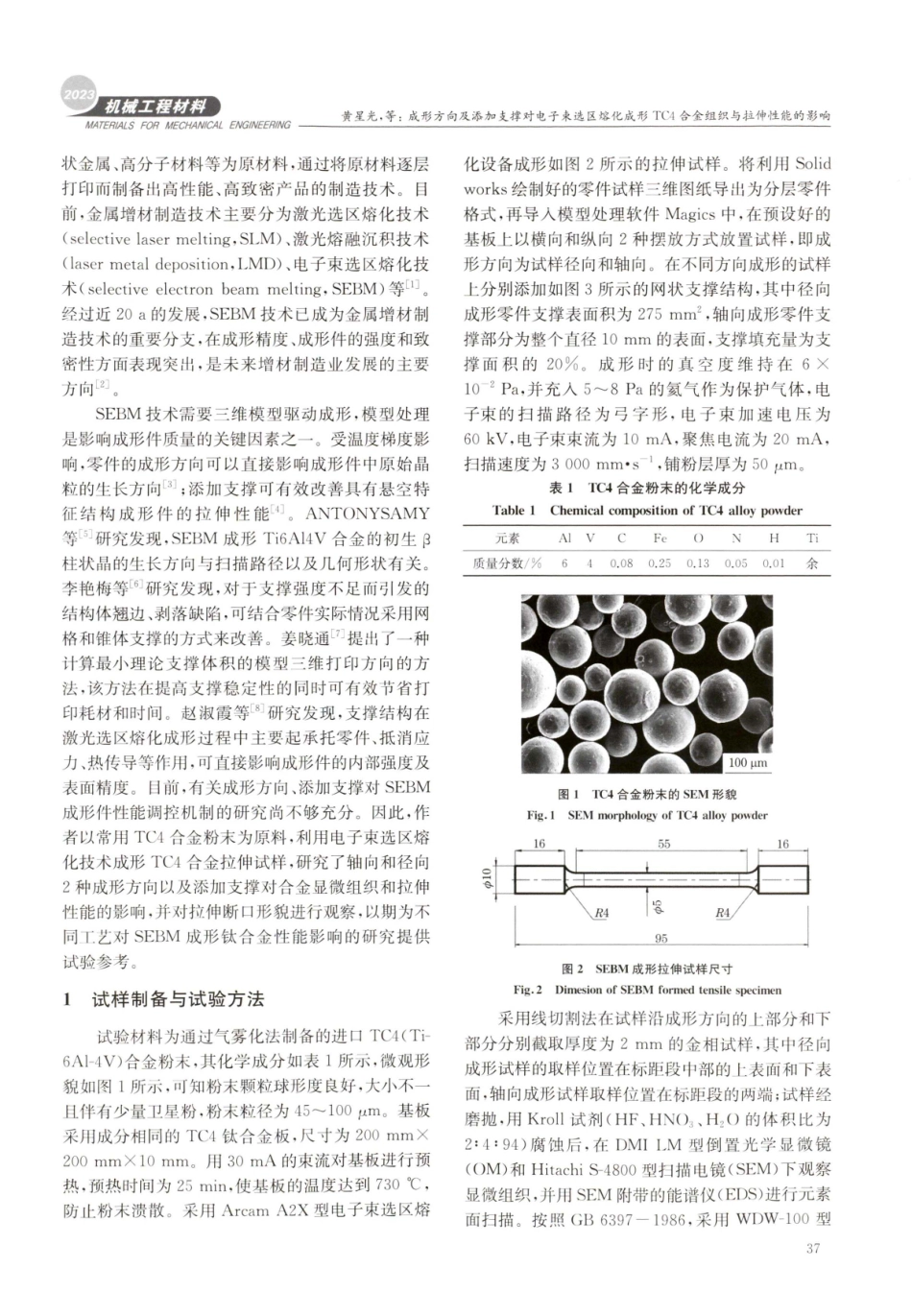

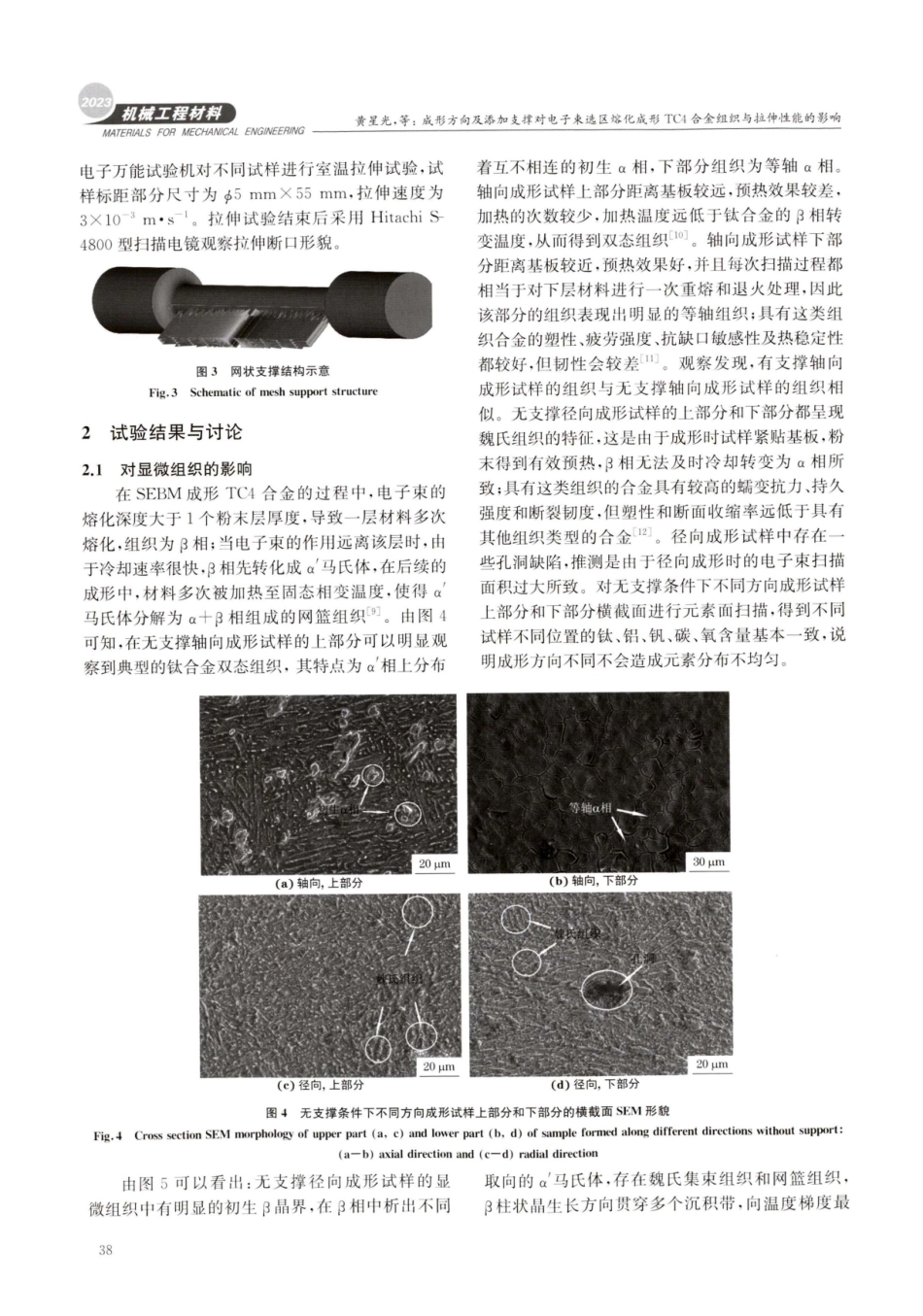

36MATERIALSFORMECHANICALENGINEERINGVol.47No.6Jun.20232023年6月第47卷第6期2023机械工程材料D0I:10.11973/jxgccl202306007成形方向及添加支撑对电子束选区熔化成形TC4合金组织与拉伸性能的影响黄星光,孙宝福,徐博翰?,张建飞3(1.桂林理工大学机械与控制工程学院,桂林541004;2.佛山桃园先进制造研究院,佛山528225;3.桂林狮达机电技术工程有限公司研发中心,桂林541004)摘要:以TC4合金粉末为原料,利用电子束选区熔化技术成形TC4合金拉伸试样,研究了轴向和径向2种成形方向以及添加支撑对合金显微组织和拉伸性能的影响。结果表明:无支撑径向成形合金存在等轴β晶及晶内针状α相,形成魏氏集束组织和网篮组织,添加支撑后由粗大β柱状晶及两侧网篮组织组成;无支撑和添加支撑轴向成形合金上部分组织由初生α相和α相组成,而下部分为等轴组织。添加支撑的径向成形合金的拉伸性能明显优于无支撑径向成形合金,其平均抗拉强度为1173.52MPa,屈服强度为1155.69MPa,断后伸长率达到15.57%,而添加支撑的轴向成形合金的拉伸性能与无支撑轴向成形合金相当,且均比径向成形合金差。关键词:电子束选区熔化;TC4合金;成形方向;添加支撑;显微组织;拉伸性能中图分类号:TG146.2文献标志码:A文章编号:1000-3738(2023)06-0036-06EffectsofFormingDirectionandAddingSupportonMicrostructureandTensilePropertiesofTC4AlloyFormedbySelectiveElectronBeamMeltingHUANGXingguang',SUNBaofu',XUBohan’,ZHANGJianfei?(1.CollegeofMechanicalandControlEngineering,GuilinUniversityofTechnology,Guilin541004,China;2.FoshanTaoyuanAdvancedInstituteofManufacturing,Foshan528225,China;3.GuilinTHDMech.&.Elec.EngineeringCo.,Ltd.,Guilin541004,China)Abstract:TakingTC4alloypowderasrawmaterial,TC4alloytensilesampleswereformedbyelectronbeamselectivemeltingtechnology.Theeffectsofaxialandradialformingdirectionsandaddingsupportonthemicrostructureandtensilepropertiesofthealloywerestudied.Theresultsshowthattherewereequiaxedβcrystalsandintragranularacicularα'phaseintheradialformedalloywithoutsupport,formingWidmanstattenclusterstructureandnetbasketstructure;afteraddingsupport,itwascomposedofcoarseβcolumnarcrystalandnetbasketstructureattwosides.Theupperpartoftheaxialformedalloywithoutandwithsuppor...