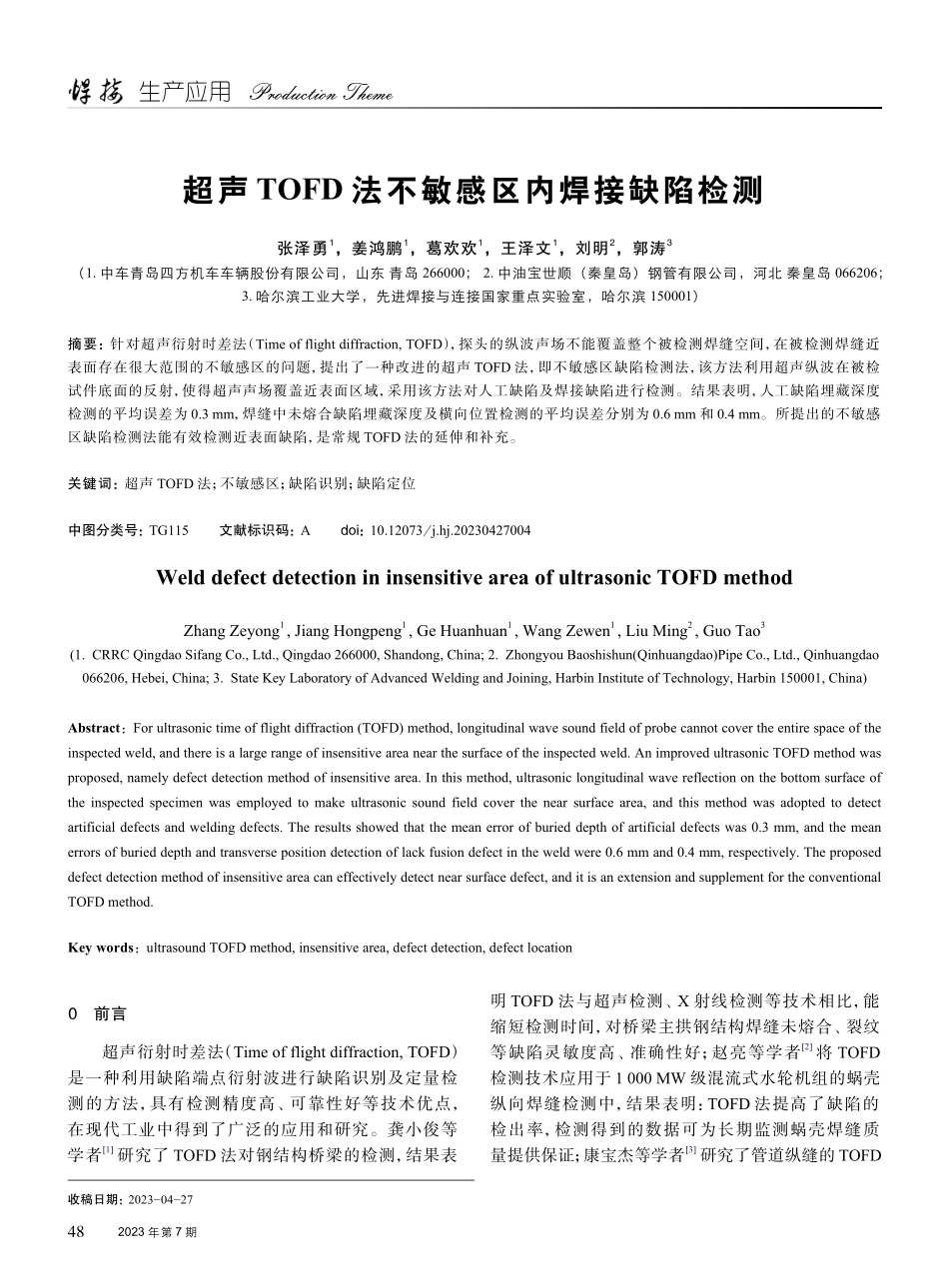

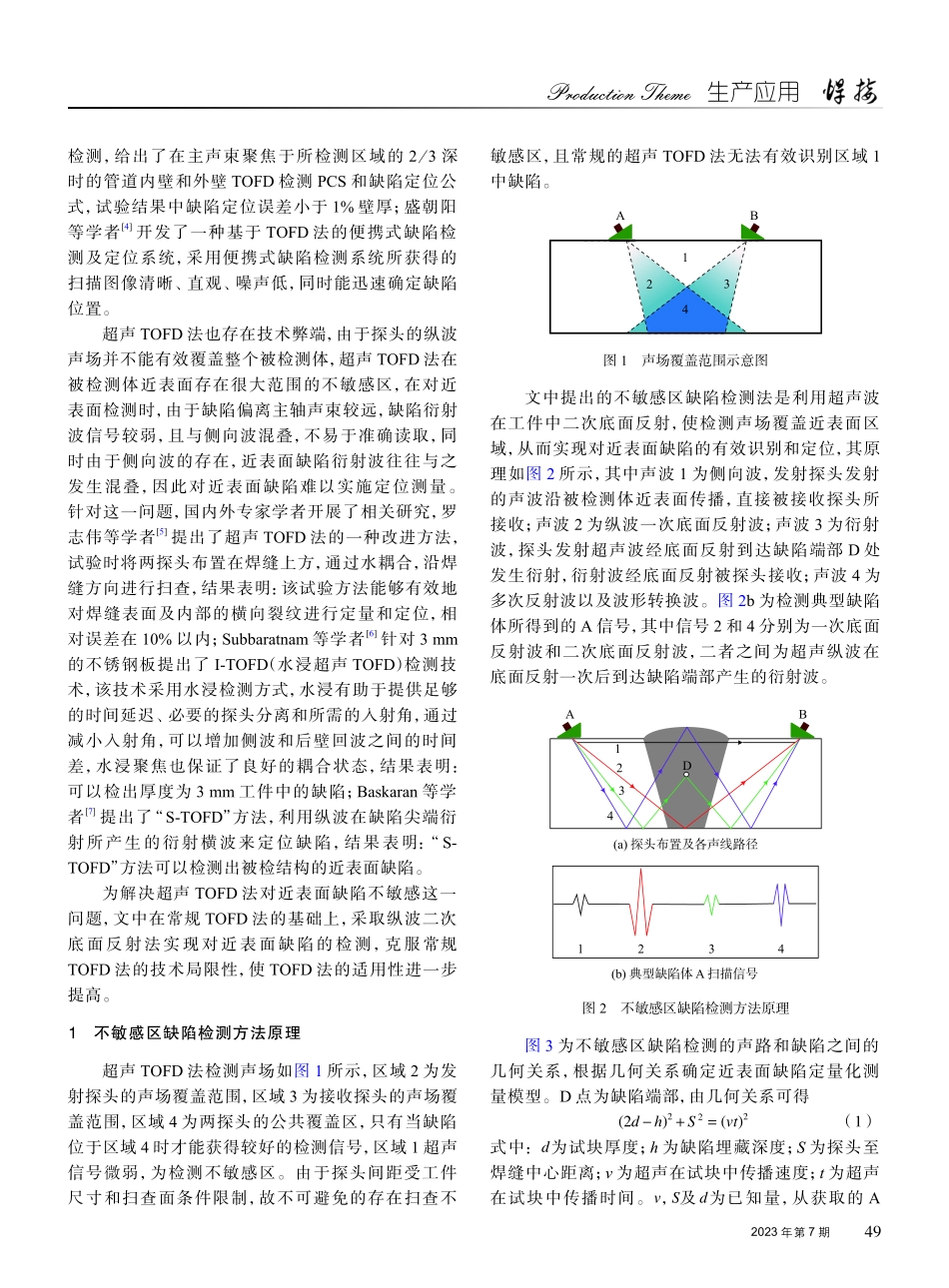

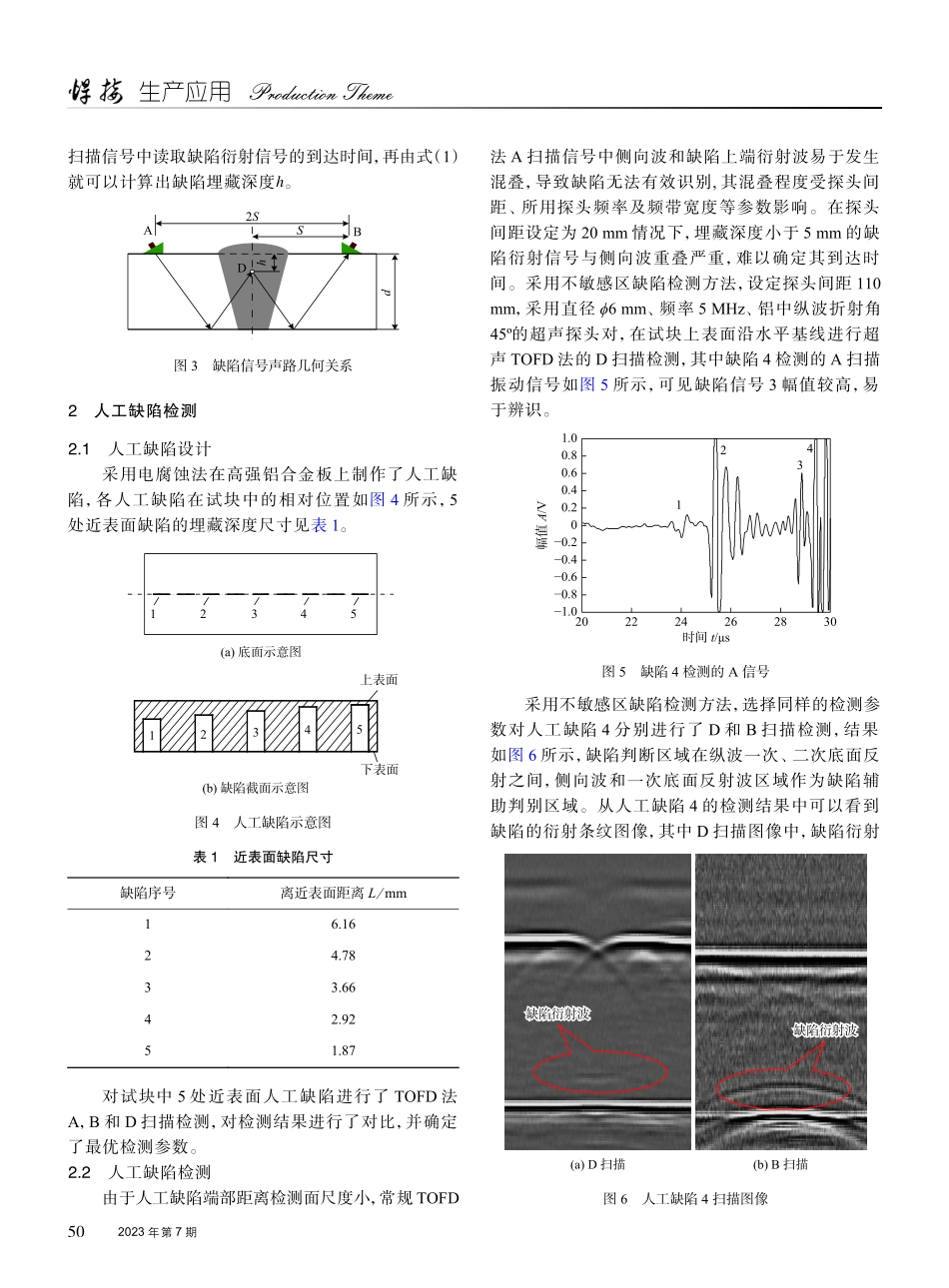

超声TOFD法不敏感区内焊接缺陷检测张泽勇1,姜鸿鹏1,葛欢欢1,王泽文1,刘明2,郭涛3(1.中车青岛四方机车车辆股份有限公司,山东青岛266000;2.中油宝世顺(秦皇岛)钢管有限公司,河北秦皇岛066206;3.哈尔滨工业大学,先进焊接与连接国家重点实验室,哈尔滨150001)摘要:针对超声衍射时差法(Timeofflightdiffraction,TOFD),探头的纵波声场不能覆盖整个被检测焊缝空间,在被检测焊缝近表面存在很大范围的不敏感区的问题,提出了一种改进的超声TOFD法,即不敏感区缺陷检测法,该方法利用超声纵波在被检试件底面的反射,使得超声声场覆盖近表面区域,采用该方法对人工缺陷及焊接缺陷进行检测。结果表明,人工缺陷埋藏深度检测的平均误差为0.3mm,焊缝中未熔合缺陷埋藏深度及横向位置检测的平均误差分别为0.6mm和0.4mm。所提出的不敏感区缺陷检测法能有效检测近表面缺陷,是常规TOFD法的延伸和补充。关键词:超声TOFD法;不敏感区;缺陷识别;缺陷定位中图分类号:TG115文献标识码:Adoi:10.12073/j.hj.20230427004WelddefectdetectionininsensitiveareaofultrasonicTOFDmethodZhangZeyong1,JiangHongpeng1,GeHuanhuan1,WangZewen1,LiuMing2,GuoTao3(1.CRRCQingdaoSifangCo.,Ltd.,Qingdao266000,Shandong,China;2.ZhongyouBaoshishun(Qinhuangdao)PipeCo.,Ltd.,Qinhuangdao066206,Hebei,China;3.StateKeyLaboratoryofAdvancedWeldingandJoining,HarbinInstituteofTechnology,Harbin150001,China)Abstract:Forultrasonictimeofflightdiffraction(TOFD)method,longitudinalwavesoundfieldofprobecannotcovertheentirespaceoftheinspectedweld,andthereisalargerangeofinsensitiveareanearthesurfaceoftheinspectedweld.AnimprovedultrasonicTOFDmethodwasproposed,namelydefectdetectionmethodofinsensitivearea.Inthismethod,ultrasoniclongitudinalwavereflectiononthebottomsurfaceoftheinspectedspecimenwasemployedtomakeultrasonicsoundfieldcoverthenearsurfacearea,andthismethodwasadoptedtodetectartificialdefectsandweldingdefects.Theresultsshowedthatthemeanerrorofburieddepthofartificialdefectswas0.3mm,andthemeanerrorsofburieddepthandtransversepositiondetectionoflackfusiondefectintheweldwere0.6mmand0.4mm,respectively.Theproposeddefectdetectionmethodofinsensitiveareacaneffectivelydetectnearsurfacedefect,a...