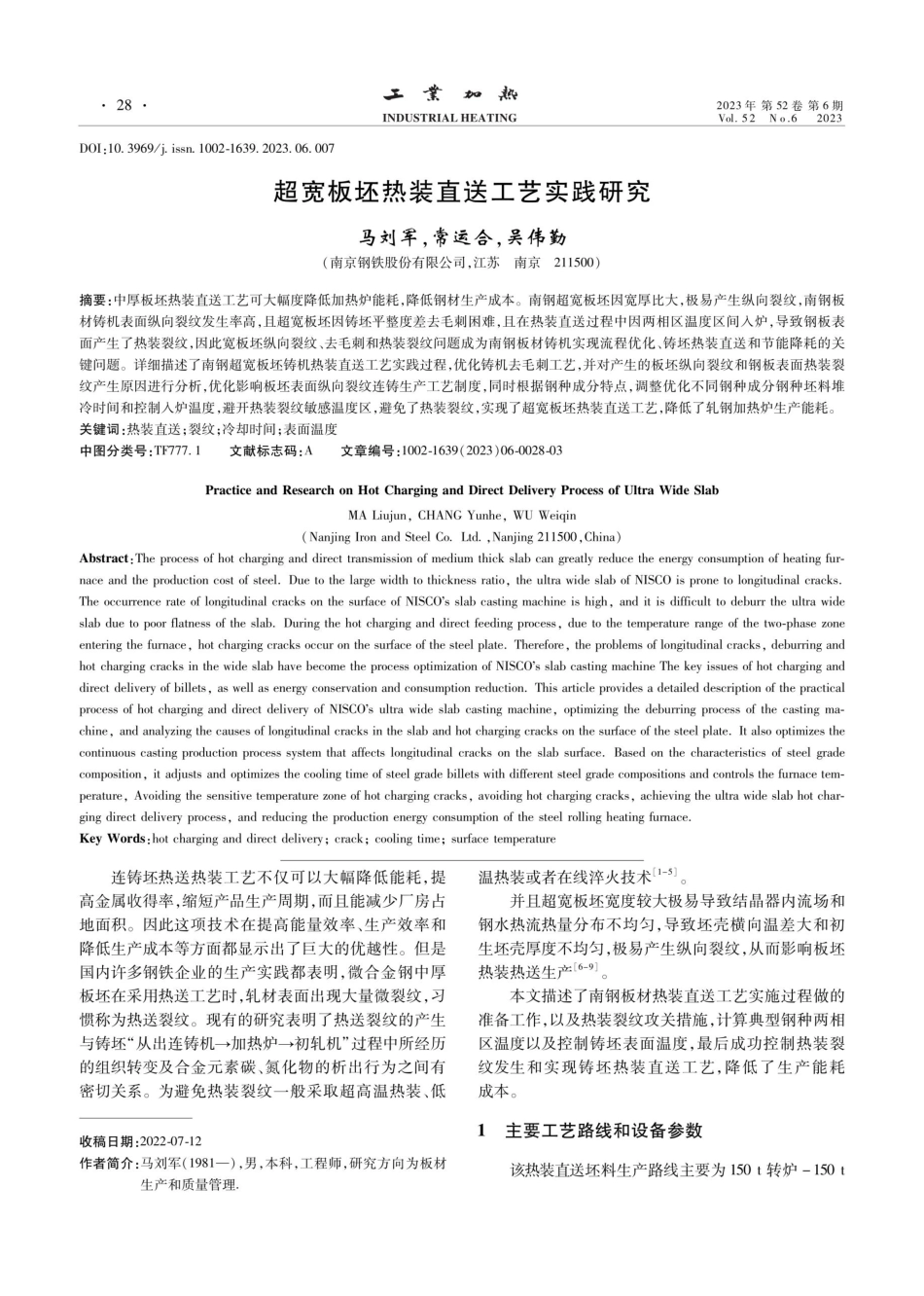

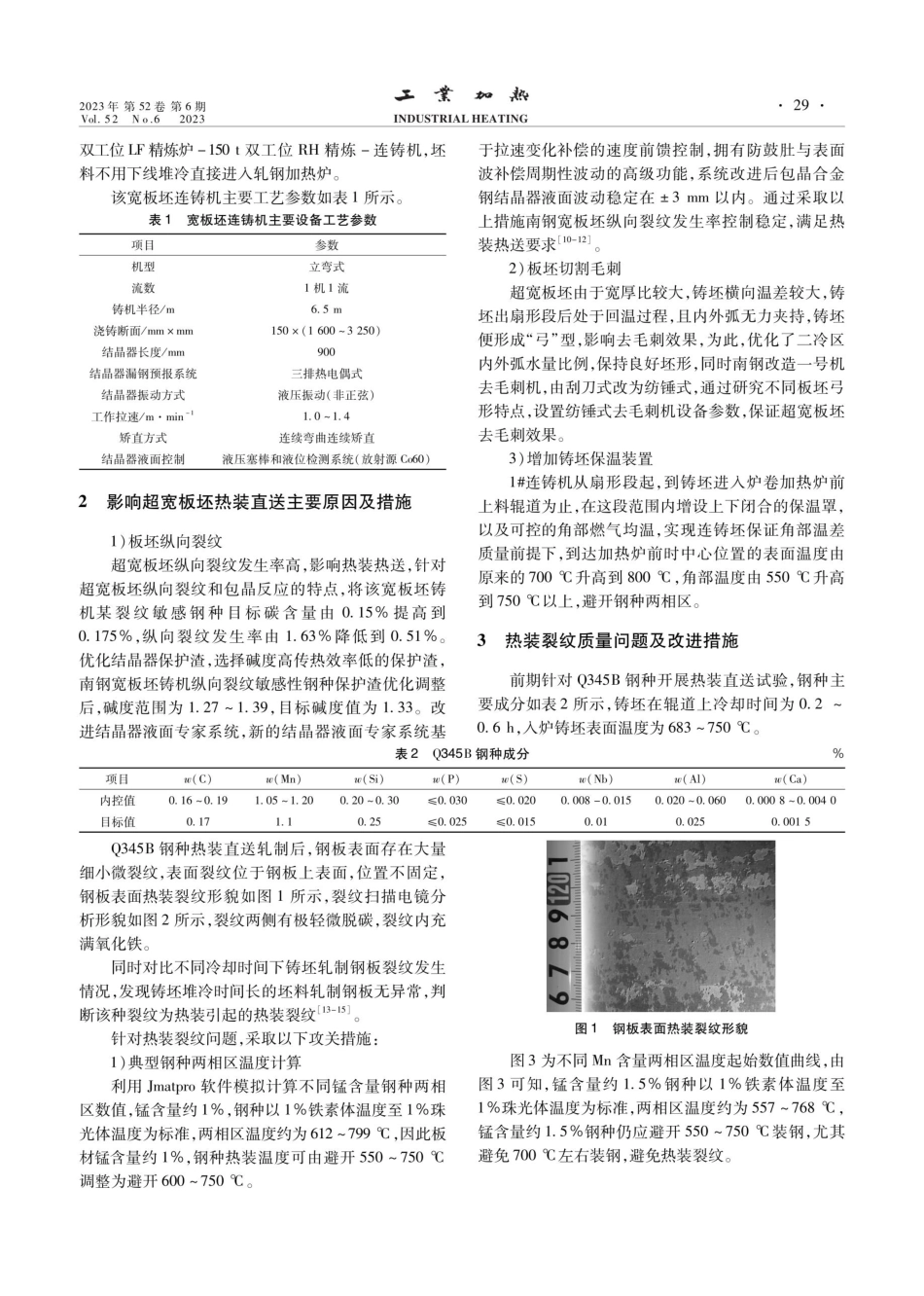

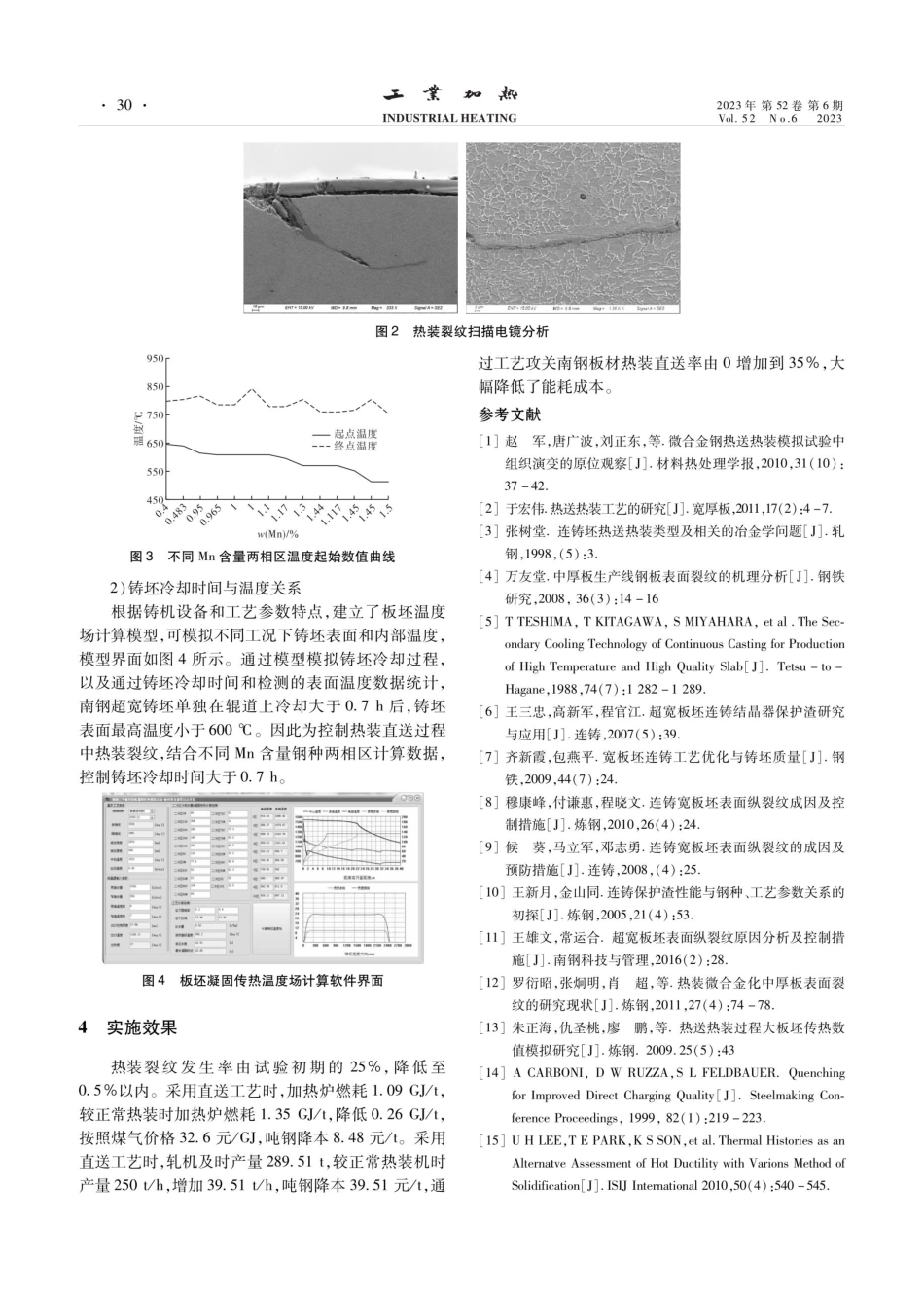

工業加熟.28·INDUSTRIALHEATINGD01:10.3969/j.issn.1002-1639.2023.06.007超宽板坏热装直送工艺实践研究马刘军,常运合,吴伟勤(南京钢铁股份有限公司,江苏南京211500)摘要:中厚板坏热装直送工艺可大幅度降低加热炉能耗,降低钢材生产成本。南钢超宽板坏因宽厚比大,极易产生纵向裂纹,南钢板材铸机表面纵向裂纹发生率高,且超宽板坏因铸坏平整度差去毛刺困难,且在热装直送过程中因两相区温度区间入炉,导致钢板表面产生了热装裂纹,因此宽板坏纵向裂纹、去毛刺和热装裂纹问题成为南钢板材铸机实现流程优化、铸坏热装直送和节能降耗的关键问题。详细描述了南钢超宽板坏铸机热装直送工艺实践过程,优化铸机去毛刺工艺,并对产生的板坏纵向裂纹和钢板表面热装裂纹产生原因进行分析,优化影响板坏表面纵向裂纹连铸生产工艺制度,同时根据钢种成分特点,调整优化不同钢种成分钢种坏料堆冷时间和控制入炉温度,避开热装裂纹敏感温度区,避免了热装裂纹,实现了超宽板坏热装直送工艺,降低了轧钢加热炉生产能耗。关键词:热装直送;裂纹;冷却时间;表面温度中图分类号:TF777.1Abstract:Theprocessofhotcharginganddirecttransmissionofmediumthickslabcangreatlyreducetheenergyconsumptionofheatingfur-naceandtheproductioncostofsteel.Duetothelargewidthtothicknessratio,theultrawideslabofNISCOispronetolongitudinalcracks.TheoccurrencerateoflongitudinalcracksonthesurfaceofNISCO'sslabcastingmachineishigh,anditisdifficulttodeburrtheultrawideslabduetopoorflatnessoftheslab.Duringthehotcharginganddirectfeedingprocess,duetothetemperaturerangeofthetwo-phasezoneenteringthefurnace,hotchargingcracksoccuronthesurfaceofthesteelplate.Therefore,theproblemsoflongitudinalcracks,deburringandhotchargingcracksinthewideslabhavebecometheprocessoptimizationofNISCO'sslabcastingmachineThekeyissuesofhotcharginganddirectdeliveryofbillets,aswellasenergyconservationandconsumptionreduction.ThisarticleprovidesadetaileddescriptionofthepracticalprocessofhotcharginganddirectdeliveryofNISCO'sultrawideslabcastingmachine,optimizingthedeburringprocessofthecastingma-chine,andanalyzingthecausesoflongitudinalcracksintheslabandhotchargingcracksonthesurfaceofthesteelplate.Italsooptimizesthecontinuo...