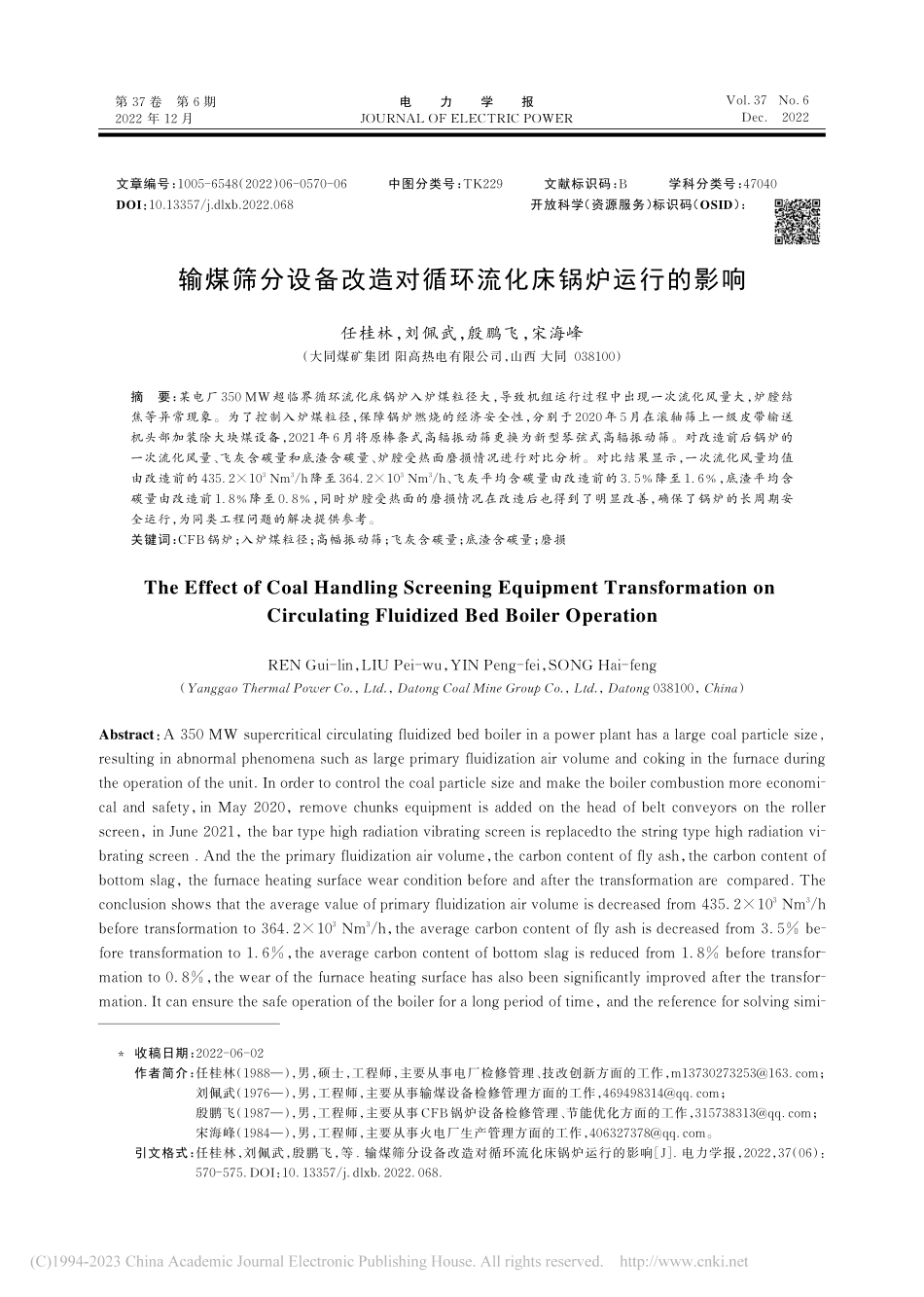

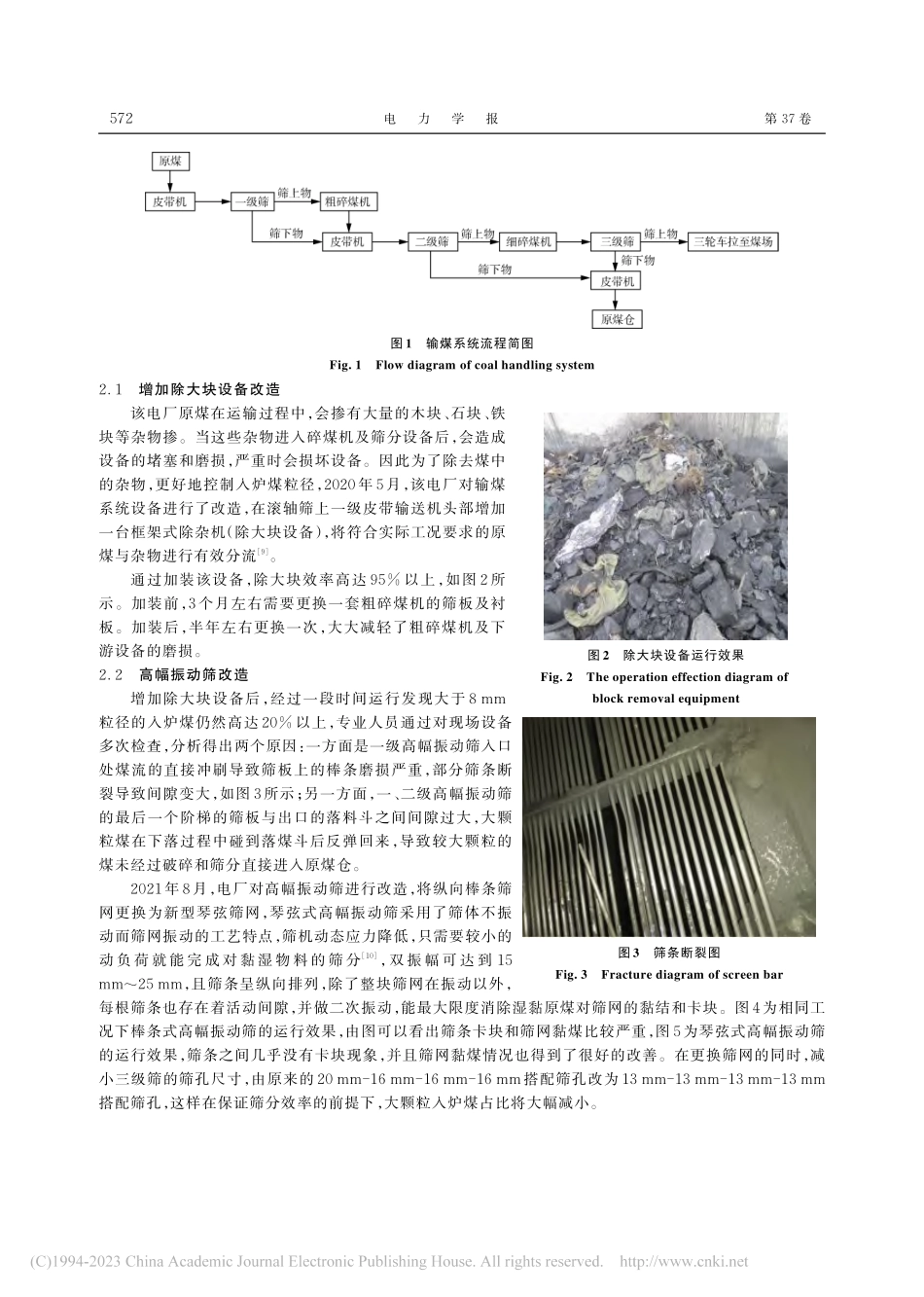

第37卷第6期2022年12月Vol.37No.6Dec.2022电力学报JOURNALOFELECTRICPOWER文章编号:1005-6548(2022)06-0570-06中图分类号:TK229文献标识码:B学科分类号:47040DOI:10.13357/j.dlxb.2022.068开放科学(资源服务)标识码(OSID):输煤筛分设备改造对循环流化床锅炉运行的影响任桂林,刘佩武,殷鹏飞,宋海峰(大同煤矿集团阳高热电有限公司,山西大同038100)摘要:某电厂350MW超临界循环流化床锅炉入炉煤粒径大,导致机组运行过程中出现一次流化风量大,炉膛结焦等异常现象。为了控制入炉煤粒径,保障锅炉燃烧的经济安全性,分别于2020年5月在滚轴筛上一级皮带输送机头部加装除大块煤设备,2021年6月将原棒条式高辐振动筛更换为新型琴弦式高辐振动筛。对改造前后锅炉的一次流化风量、飞灰含碳量和底渣含碳量、炉膛受热面磨损情况进行对比分析。对比结果显示,一次流化风量均值由改造前的435.2×103Nm3/h降至364.2×103Nm3/h、飞灰平均含碳量由改造前的3.5%降至1.6%,底渣平均含碳量由改造前1.8%降至0.8%,同时炉膛受热面的磨损情况在改造后也得到了明显改善,确保了锅炉的长周期安全运行,为同类工程问题的解决提供参考。关键词:CFB锅炉;入炉煤粒径;高幅振动筛;飞灰含碳量;底渣含碳量;磨损TheEffectofCoalHandlingScreeningEquipmentTransformationonCirculatingFluidizedBedBoilerOperationRENGui-lin,LIUPei-wu,YINPeng-fei,SONGHai-feng(YanggaoThermalPowerCo.,Ltd.,DatongCoalMineGroupCo.,Ltd.,Datong038100,China)Abstract:A350MWsupercriticalcirculatingfluidizedbedboilerinapowerplanthasalargecoalparticlesize,resultinginabnormalphenomenasuchaslargeprimaryfluidizationairvolumeandcokinginthefurnaceduringtheoperationoftheunit.Inordertocontrolthecoalparticlesizeandmaketheboilercombustionmoreeconomi⁃calandsafety,inMay2020,removechunksequipmentisaddedontheheadofbeltconveyorsontherollerscreen,inJune2021,thebartypehighradiationvibratingscreenisreplacedtothestringtypehighradiationvi⁃bratingscreen.Andthetheprimaryfluidizationairvolume,thecarboncontentofflyash,thecarboncontentofbottomslag,thefurnaceheatingsurfacewearconditionbeforeandafterthetransformationarecompared.Theconclusionshowsthattheaveragevalueofprimaryfluidizationairvolumeisdecreasedf...