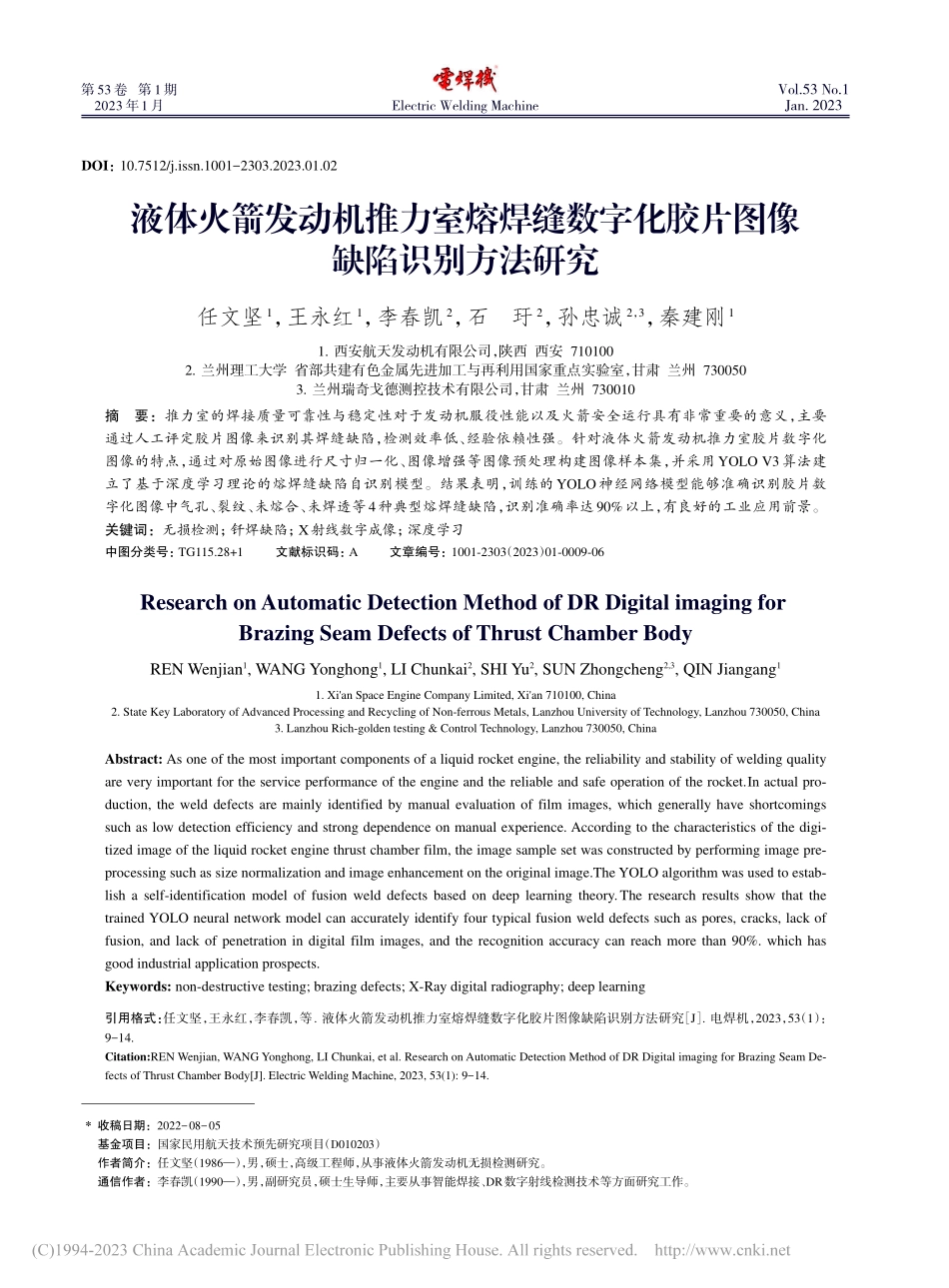

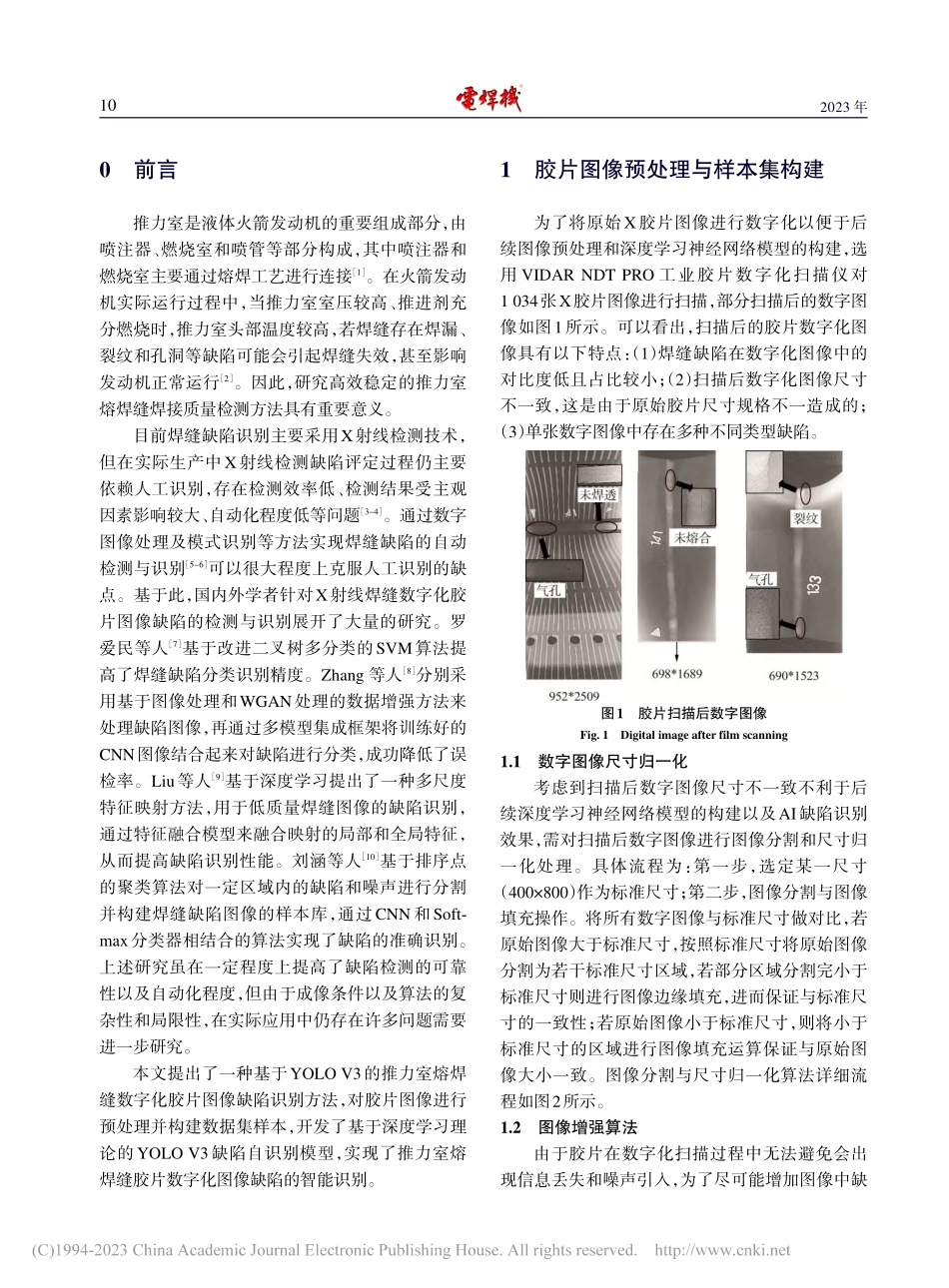

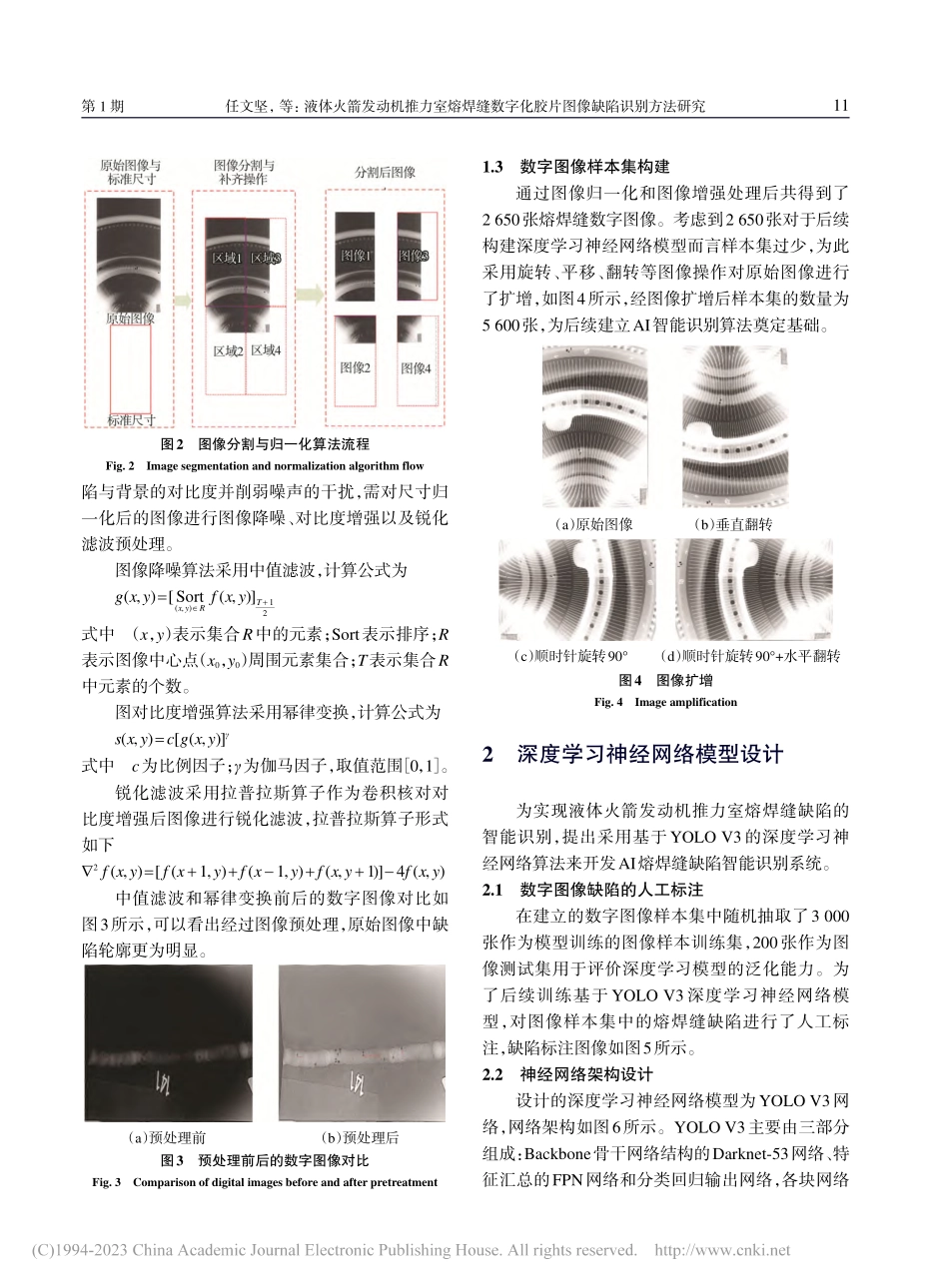

ElectricWeldingMachineVol.53No.1Jan.2023第53卷第1期2023年1月液体火箭发动机推力室熔焊缝数字化胶片图像缺陷识别方法研究任文坚1,王永红1,李春凯2,石玗2,孙忠诚2,3,秦建刚11.西安航天发动机有限公司,陕西西安7101002.兰州理工大学省部共建有色金属先进加工与再利用国家重点实验室,甘肃兰州7300503.兰州瑞奇戈德测控技术有限公司,甘肃兰州730010摘要:推力室的焊接质量可靠性与稳定性对于发动机服役性能以及火箭安全运行具有非常重要的意义,主要通过人工评定胶片图像来识别其焊缝缺陷,检测效率低、经验依赖性强。针对液体火箭发动机推力室胶片数字化图像的特点,通过对原始图像进行尺寸归一化、图像增强等图像预处理构建图像样本集,并采用YOLOV3算法建立了基于深度学习理论的熔焊缝缺陷自识别模型。结果表明,训练的YOLO神经网络模型能够准确识别胶片数字化图像中气孔、裂纹、未熔合、未焊透等4种典型熔焊缝缺陷,识别准确率达90%以上,有良好的工业应用前景。关键词:无损检测;钎焊缺陷;X射线数字成像;深度学习中图分类号:TG115.28+1文献标识码:A文章编号:1001-2303(2023)01-0009-06ResearchonAutomaticDetectionMethodofDRDigitalimagingforBrazingSeamDefectsofThrustChamberBodyRENWenjian1,WANGYonghong1,LIChunkai2,SHIYu2,SUNZhongcheng2,3,QINJiangang11.Xi'anSpaceEngineCompanyLimited,Xi'an710100,China2.StateKeyLaboratoryofAdvancedProcessingandRecyclingofNon-ferrousMetals,LanzhouUniversityofTechnology,Lanzhou730050,China3.LanzhouRich-goldentesting&ControlTechnology,Lanzhou730050,ChinaAbstract:Asoneofthemostimportantcomponentsofaliquidrocketengine,thereliabilityandstabilityofweldingqualityareveryimportantfortheserviceperformanceoftheengineandthereliableandsafeoperationoftherocket.Inactualpro‐duction,thewelddefectsaremainlyidentifiedbymanualevaluationoffilmimages,whichgenerallyhaveshortcomingssuchaslowdetectionefficiencyandstrongdependenceonmanualexperience.Accordingtothecharacteristicsofthedigi‐tizedimageoftheliquidrocketenginethrustchamberfilm,theimagesamplesetwasconstructedbyperformingimagepre‐processingsuchassizenormalizationandimageenhancementontheoriginalimage.TheYOLOalgorithmwasusedtoestab‐lishaself-identificationmodeloffu...