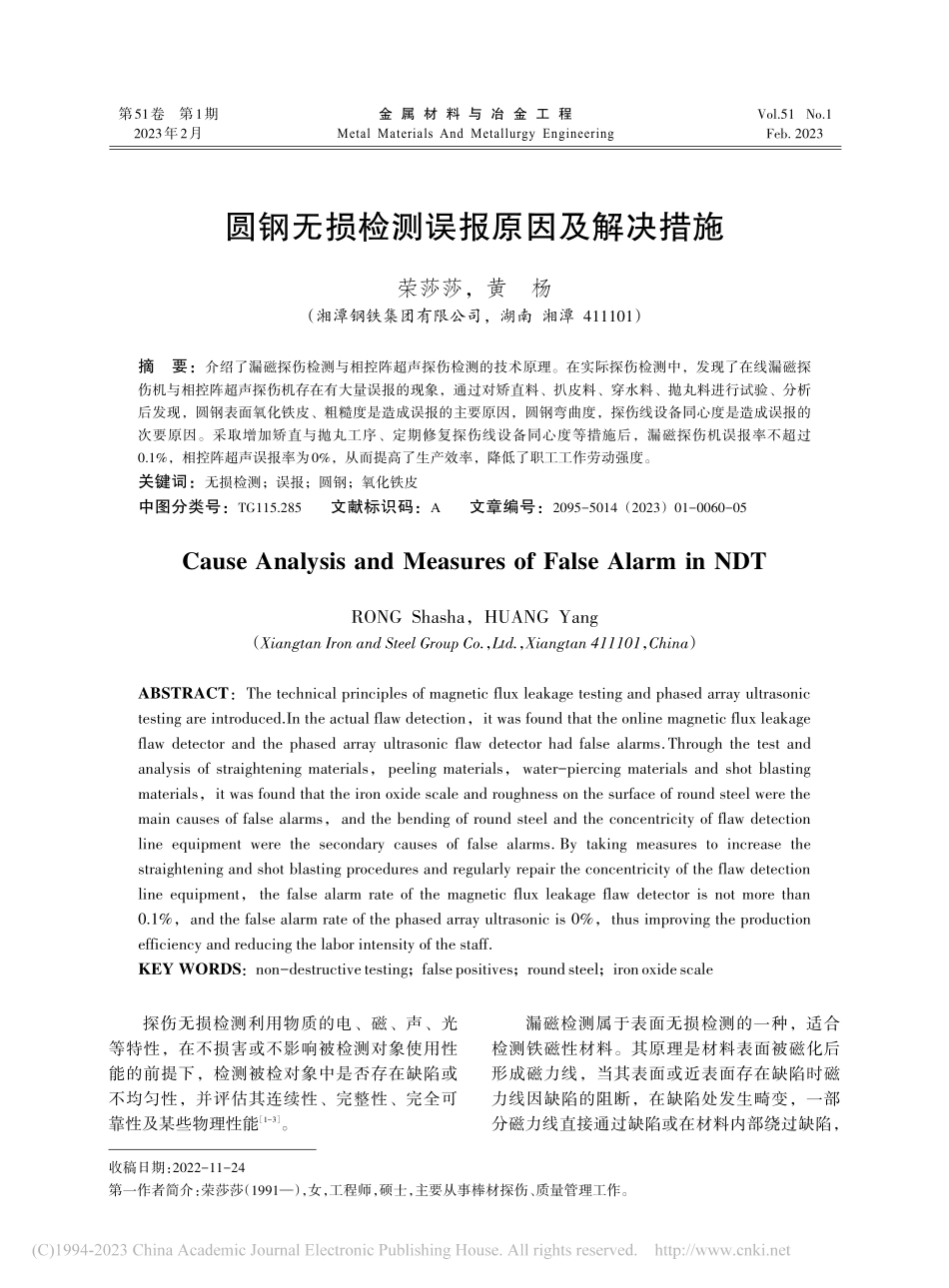

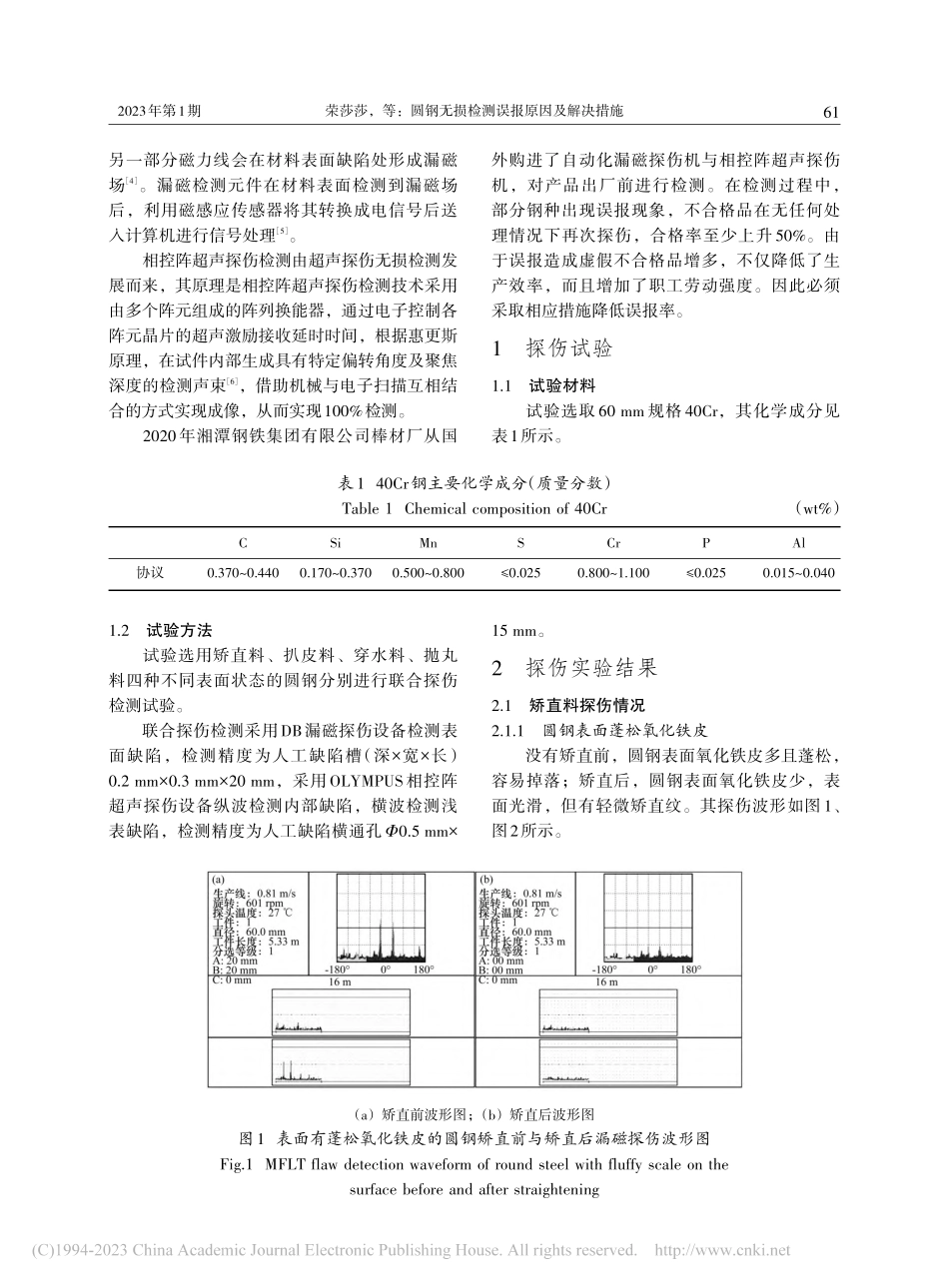

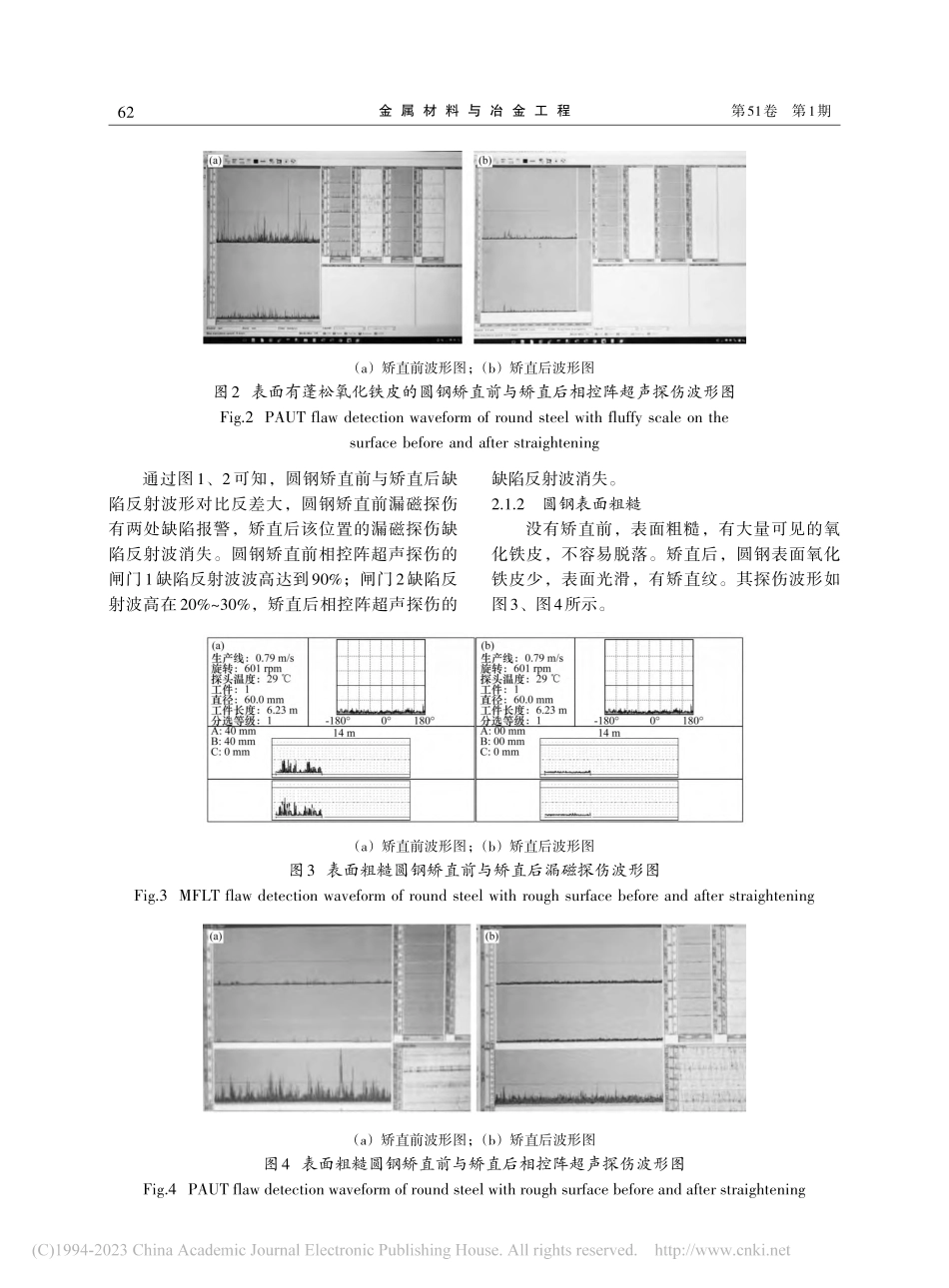

金属材料与冶金工程第51卷第1期圆钢无损检测误报原因及解决措施荣莎莎,黄杨(湘潭钢铁集团有限公司,湖南湘潭411101)摘要:介绍了漏磁探伤检测与相控阵超声探伤检测的技术原理。在实际探伤检测中,发现了在线漏磁探伤机与相控阵超声探伤机存在有大量误报的现象,通过对矫直料、扒皮料、穿水料、抛丸料进行试验、分析后发现,圆钢表面氧化铁皮、粗糙度是造成误报的主要原因,圆钢弯曲度,探伤线设备同心度是造成误报的次要原因。采取增加矫直与抛丸工序、定期修复探伤线设备同心度等措施后,漏磁探伤机误报率不超过0.1%,相控阵超声误报率为0%,从而提高了生产效率,降低了职工工作劳动强度。关键词:无损检测;误报;圆钢;氧化铁皮中图分类号:TG115.285文献标识码:A文章编号:2095-5014(2023)01-0060-05CauseAnalysisandMeasuresofFalseAlarminNDTRONGShasha,HUANGYang(XiangtanIronandSteelGroupCo.,Ltd.,Xiangtan411101,China)ABSTRACT:Thetechnicalprinciplesofmagneticfluxleakagetestingandphasedarrayultrasonictestingareintroduced.Intheactualflawdetection,itwasfoundthattheonlinemagneticfluxleakageflawdetectorandthephasedarrayultrasonicflawdetectorhadfalsealarms.Throughthetestandanalysisofstraighteningmaterials,peelingmaterials,water-piercingmaterialsandshotblastingmaterials,itwasfoundthattheironoxidescaleandroughnessonthesurfaceofroundsteelwerethemaincausesoffalsealarms,andthebendingofroundsteelandtheconcentricityofflawdetectionlineequipmentwerethesecondarycausesoffalsealarms.Bytakingmeasurestoincreasethestraighteningandshotblastingproceduresandregularlyrepairtheconcentricityoftheflawdetectionlineequipment,thefalsealarmrateofthemagneticfluxleakageflawdetectorisnotmorethan0.1%,andthefalsealarmrateofthephasedarrayultrasonicis0%,thusimprovingtheproductionefficiencyandreducingthelaborintensityofthestaff.KEYWORDS:non-destructivetesting;falsepositives;roundsteel;ironoxidescale收稿日期:2022-11-24第一作者简介:荣莎莎(1991—),女,工程师,硕士,主要从事棒材探伤、质量管理工作。金属材料与冶金工程MetalMaterialsAndMetallurgyEngineering第51卷第1期2023年2月Vol.51No.1Feb.2023探伤无损检测利用物质的电、磁、声、光等特性,...