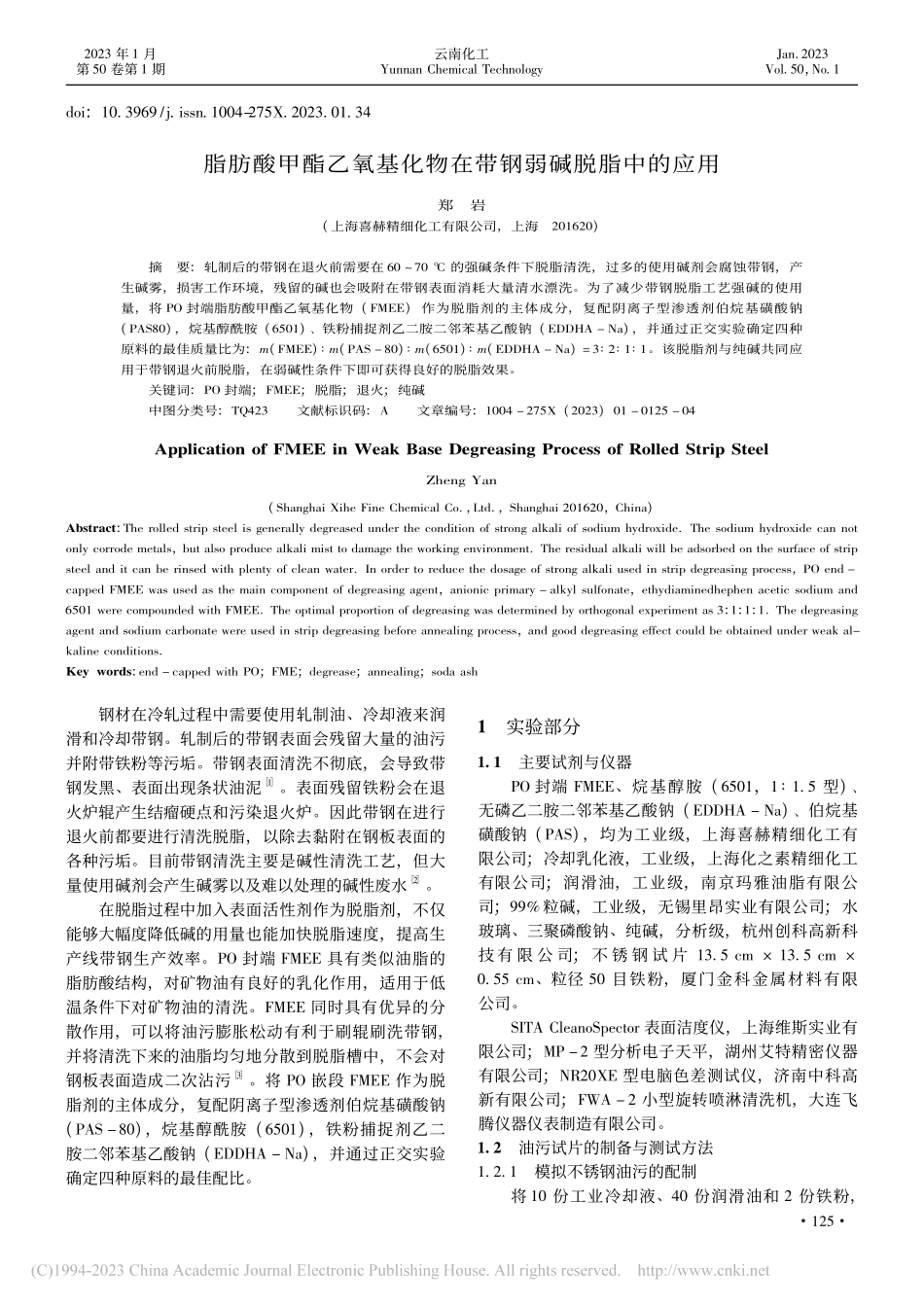

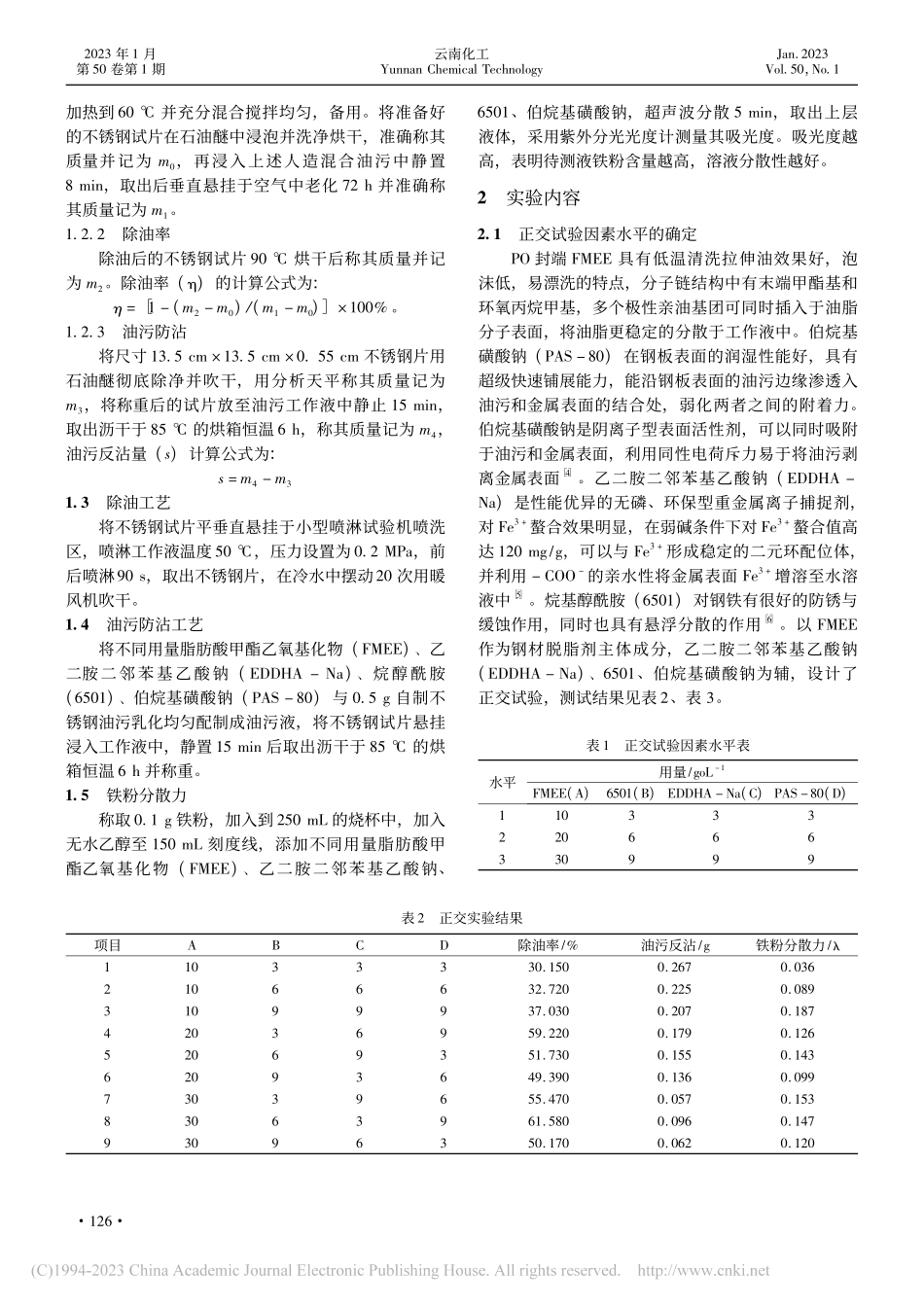

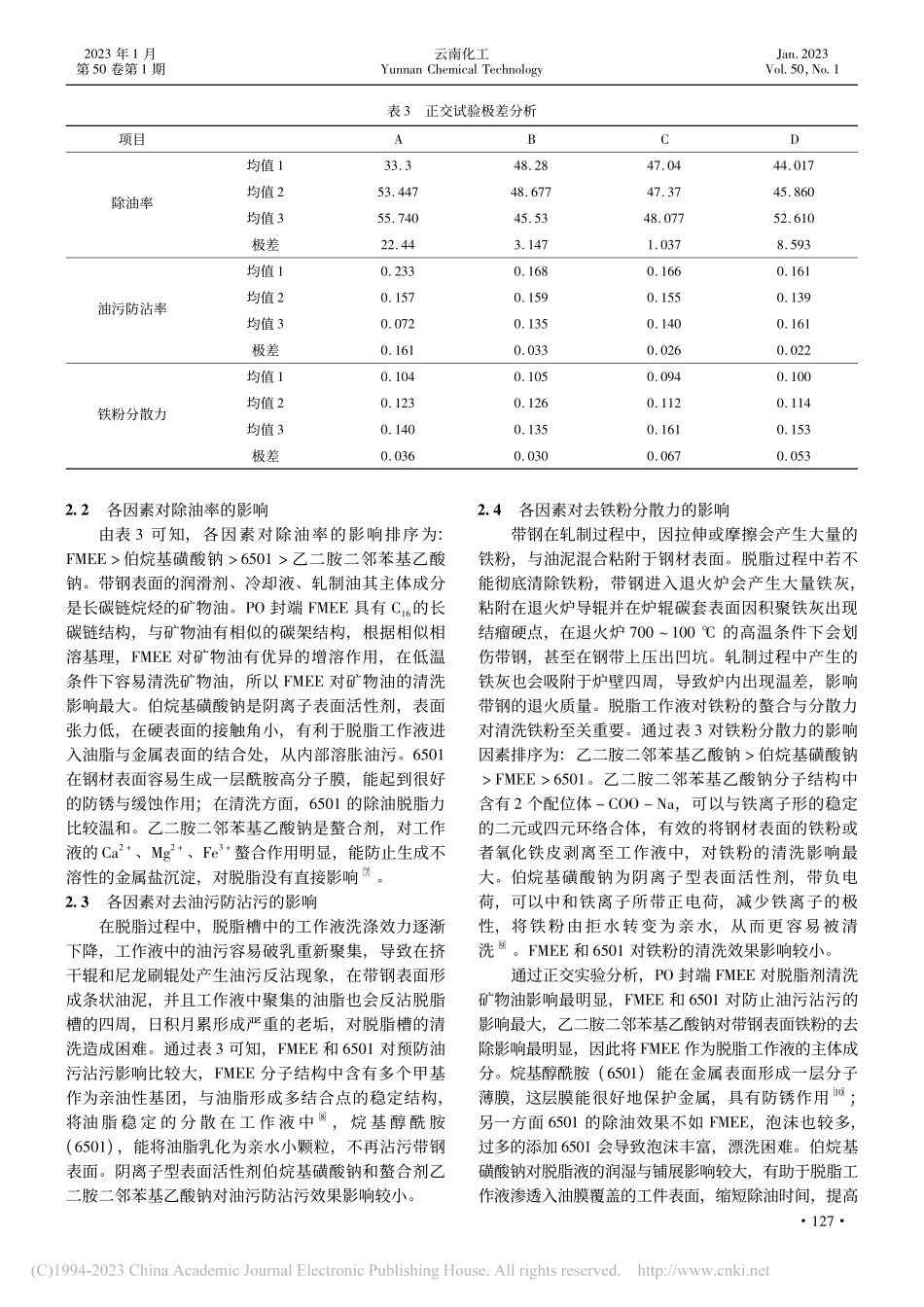

2023年1月云南化工Jan.2023第50卷第1期YunnanChemicalTechnologyVol.50,No.1doi:10.3969/j.issn.1004-275X.2023.01.34脂肪酸甲酯乙氧基化物在带钢弱碱脱脂中的应用郑岩(上海喜赫精细化工有限公司,上海201620)摘要:轧制后的带钢在退火前需要在60~70℃的强碱条件下脱脂清洗,过多的使用碱剂会腐蚀带钢,产生碱雾,损害工作环境,残留的碱也会吸附在带钢表面消耗大量清水漂洗。为了减少带钢脱脂工艺强碱的使用量,将PO封端脂肪酸甲酯乙氧基化物(FMEE)作为脱脂剂的主体成分,复配阴离子型渗透剂伯烷基磺酸钠(PAS80),烷基醇酰胺(6501)、铁粉捕捉剂乙二胺二邻苯基乙酸钠(EDDHA-Na),并通过正交实验确定四种原料的最佳质量比为:m(FMEE)∶m(PAS-80)∶m(6501)∶m(EDDHA-Na)=3∶2∶1∶1。该脱脂剂与纯碱共同应用于带钢退火前脱脂,在弱碱性条件下即可获得良好的脱脂效果。关键词:PO封端;FMEE;脱脂;退火;纯碱中图分类号:TQ423文献标识码:A文章编号:1004-275X(2023)01-0125-04ApplicationofFMEEinWeakBaseDegreasingProcessofRolledStripSteelZhengYan(ShanghaiXiheFineChemicalCo.,Ltd.,Shanghai201620,China)Abstract:Therolledstripsteelisgenerallydegreasedundertheconditionofstrongalkaliofsodiumhydroxide.Thesodiumhydroxidecannotonlycorrodemetals,butalsoproducealkalimisttodamagetheworkingenvironment.Theresidualalkaliwillbeadsorbedonthesurfaceofstripsteelanditcanberinsedwithplentyofcleanwater.Inordertoreducethedosageofstrongalkaliusedinstripdegreasingprocess,POend-cappedFMEEwasusedasthemaincomponentofdegreasingagent,anionicprimary-alkylsulfonate,ethydiaminedhephenaceticsodiumand6501werecompoundedwithFMEE.Theoptimalproportionofdegreasingwasdeterminedbyorthogonalexperimentas3:1:1:1.Thedegreasingagentandsodiumcarbonatewereusedinstripdegreasingbeforeannealingprocess,andgooddegreasingeffectcouldbeobtainedunderweakal-kalineconditions.Keywords:end-cappedwithPO;FME;degrease;annealing;sodaash钢材在冷轧过程中需要使用轧制油、冷却液来润滑和冷却带钢。轧制后的带钢表面会残留大量的油污并附带铁粉等污垢。带钢表面清洗不彻底,会导致带钢发黑、表面出现条状油泥[1]。表面残留铁粉会在退火炉辊产生结瘤硬点和污染退火炉。因此带钢在进行退火前都要进行清洗脱脂...