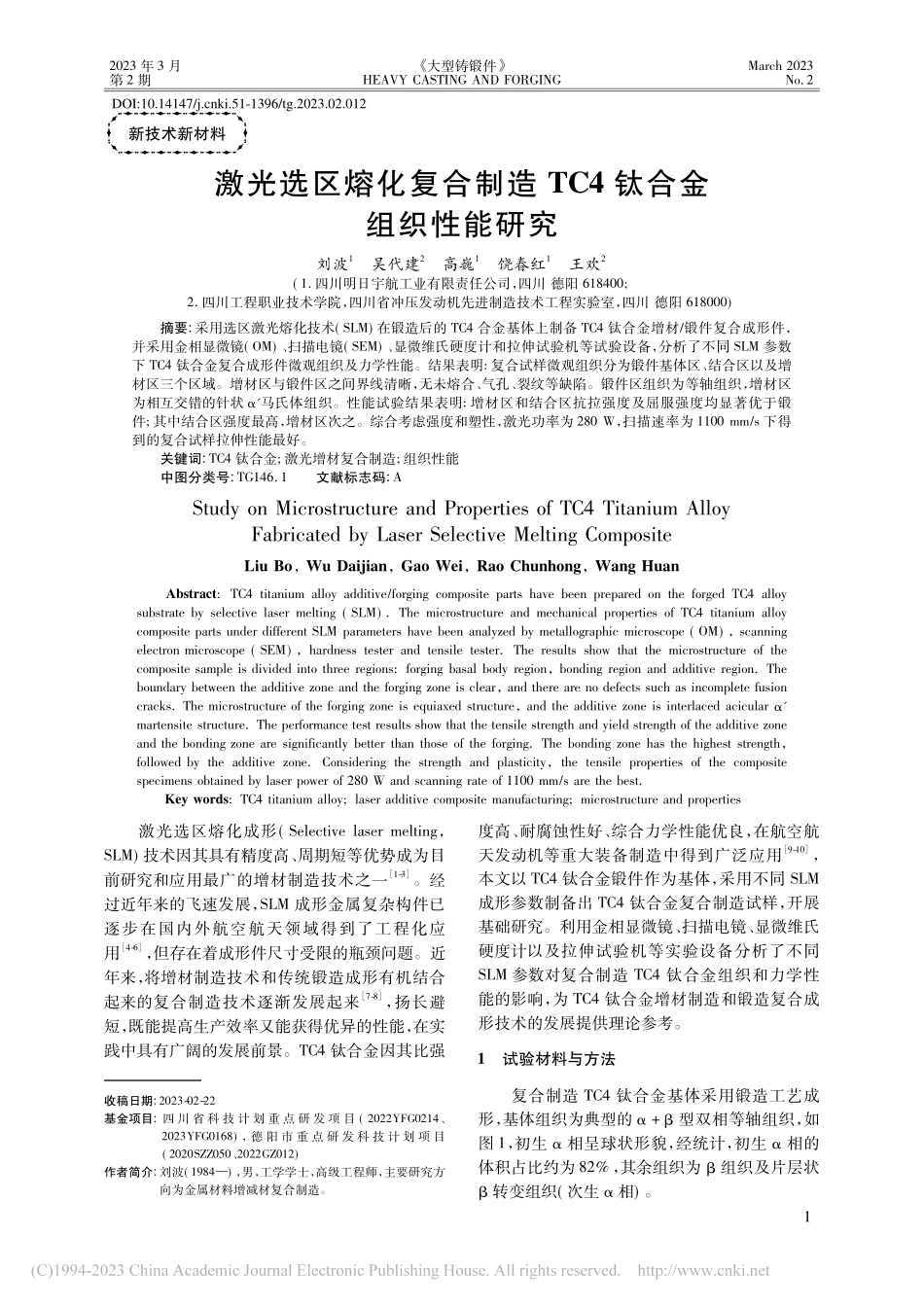

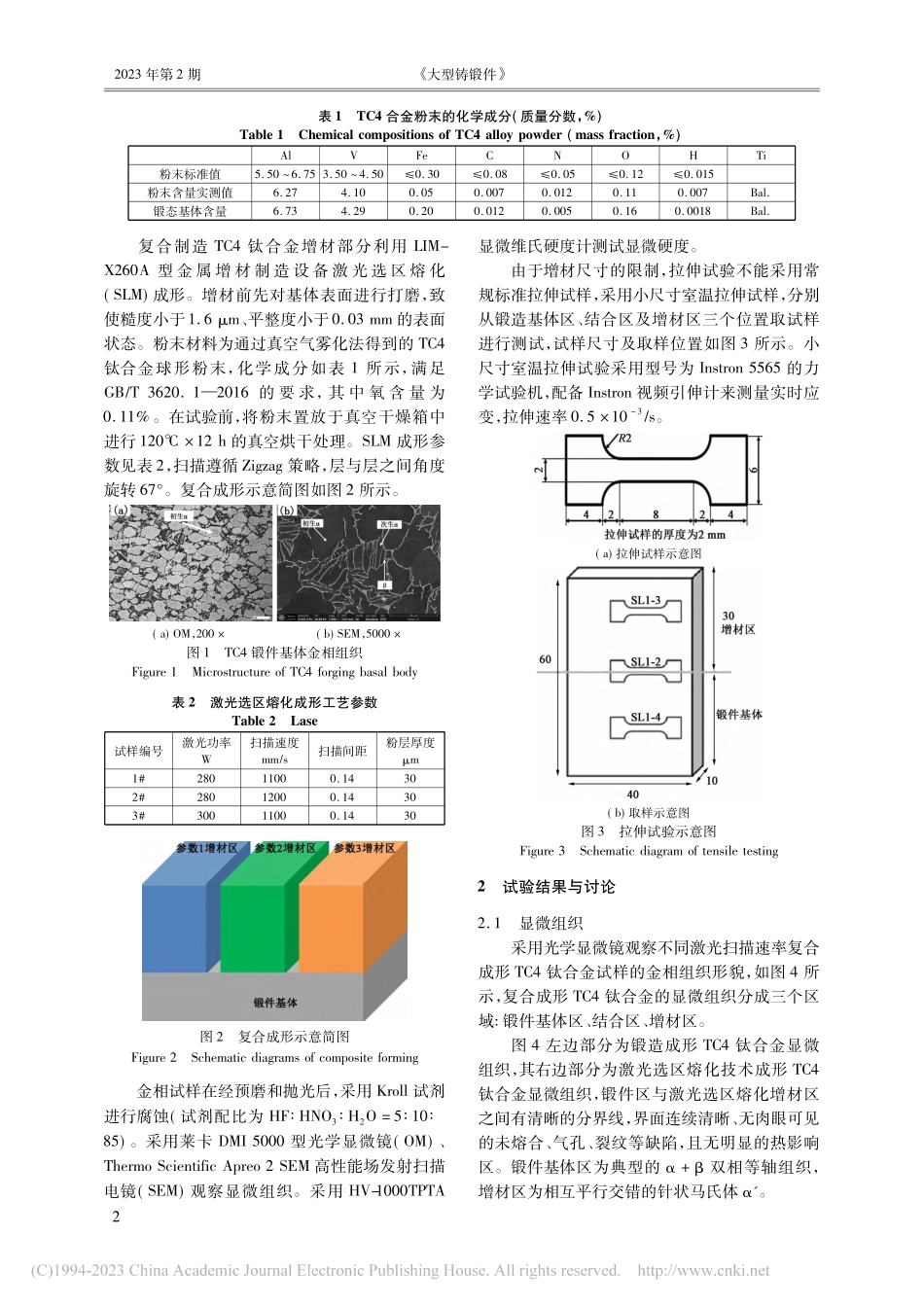

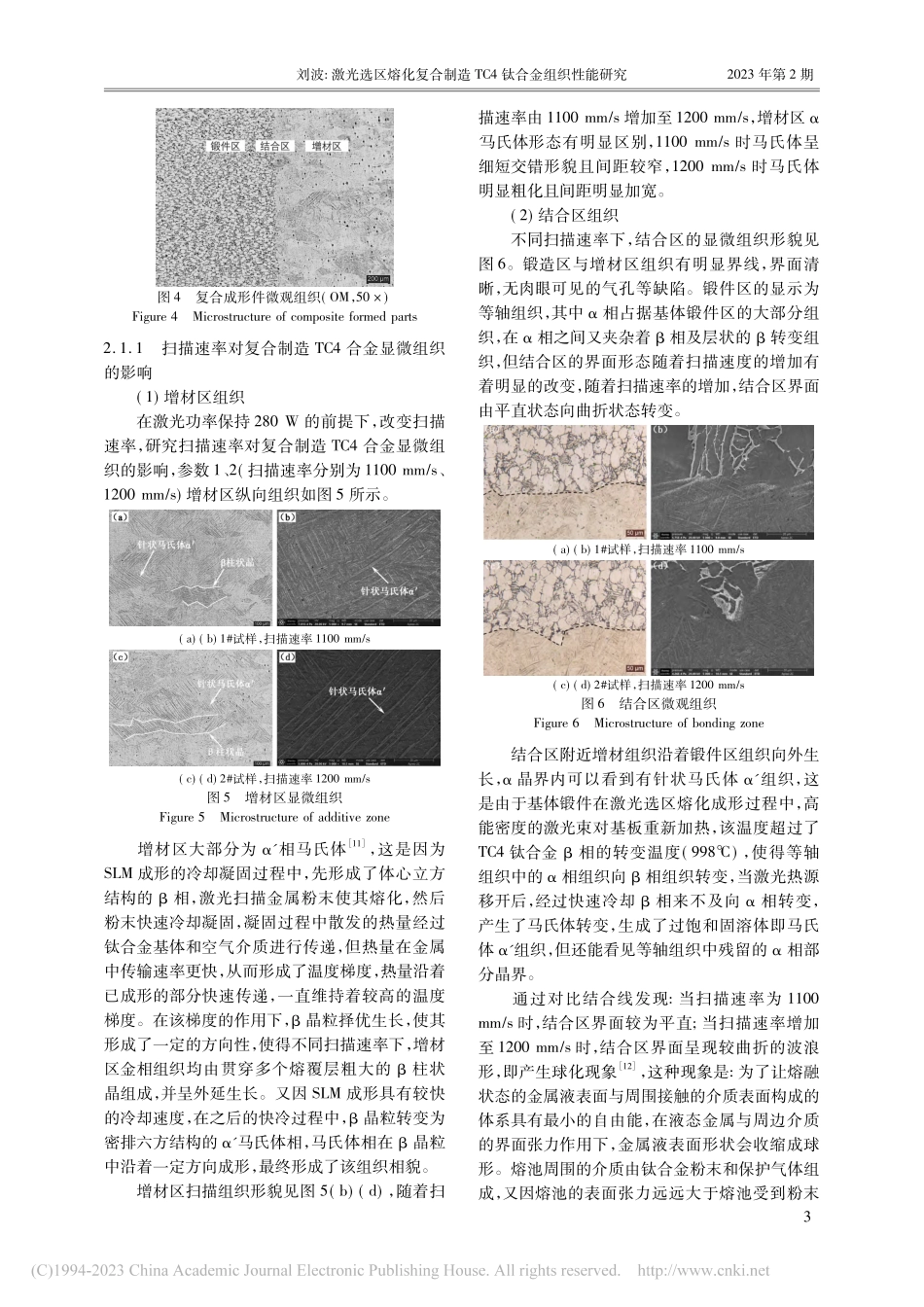

2023年3月第2期《大型铸锻件》HEAVYCASTINGANDFORGINGMarch2023No.2櫂櫂櫂櫂櫂櫂櫂櫂櫂櫂櫂櫂櫂櫂櫂櫂殬殬殬殬新技术新材料激光选区熔化复合制造TC4钛合金组织性能研究刘波1吴代建2高巍1饶春红1王欢2(1.四川明日宇航工业有限责任公司,四川德阳618400;2.四川工程职业技术学院,四川省冲压发动机先进制造技术工程实验室,四川德阳618000)摘要:采用选区激光熔化技术(SLM)在锻造后的TC4合金基体上制备TC4钛合金增材锻件复合成形件,并采用金相显微镜(OM)、扫描电镜(SEM)、显微维氏硬度计和拉伸试验机等试验设备,分析了不同SLM参数下TC4钛合金复合成形件微观组织及力学性能。结果表明:复合试样微观组织分为锻件基体区、结合区以及增材区三个区域。增材区与锻件区之间界线清晰,无未熔合、气孔、裂纹等缺陷。锻件区组织为等轴组织,增材区为相互交错的针状α'马氏体组织。性能试验结果表明:增材区和结合区抗拉强度及屈服强度均显著优于锻件;其中结合区强度最高,增材区次之。综合考虑强度和塑性,激光功率为280W,扫描速率为1100mms下得到的复合试样拉伸性能最好。关键词:TC4钛合金;激光增材复合制造;组织性能中图分类号:TG146.1文献标志码:AStudyonMicrostructureandPropertiesofTC4TitaniumAlloyFabricatedbyLaserSelectiveMeltingCompositeLiuBo,WuDaijian,GaoWei,RaoChunhong,WangHuanAbstract:TC4titaniumalloyadditiveforgingcompositepartshavebeenpreparedontheforgedTC4alloysubstratebyselectivelasermelting(SLM).ThemicrostructureandmechanicalpropertiesofTC4titaniumalloycompositepartsunderdifferentSLMparametershavebeenanalyzedbymetallographicmicroscope(OM),scanningelectronmicroscope(SEM),hardnesstesterandtensiletester.Theresultsshowthatthemicrostructureofthecompositesampleisdividedintothreeregions:forgingbasalbodyregion,bondingregionandadditiveregion.Theboundarybetweentheadditivezoneandtheforgingzoneisclear,andtherearenodefectssuchasincompletefusioncracks.Themicrostructureoftheforgingzoneisequiaxedstructure,andtheadditivezoneisinterlacedacicularα'martensitestructure.Theperformancetestresultsshowthatthetensilestrengthandyieldstrengthoftheadditivezoneandthebondingzonearesignificantlybetterthanthoseoftheforging.Thebondingzonehasthehigheststren...