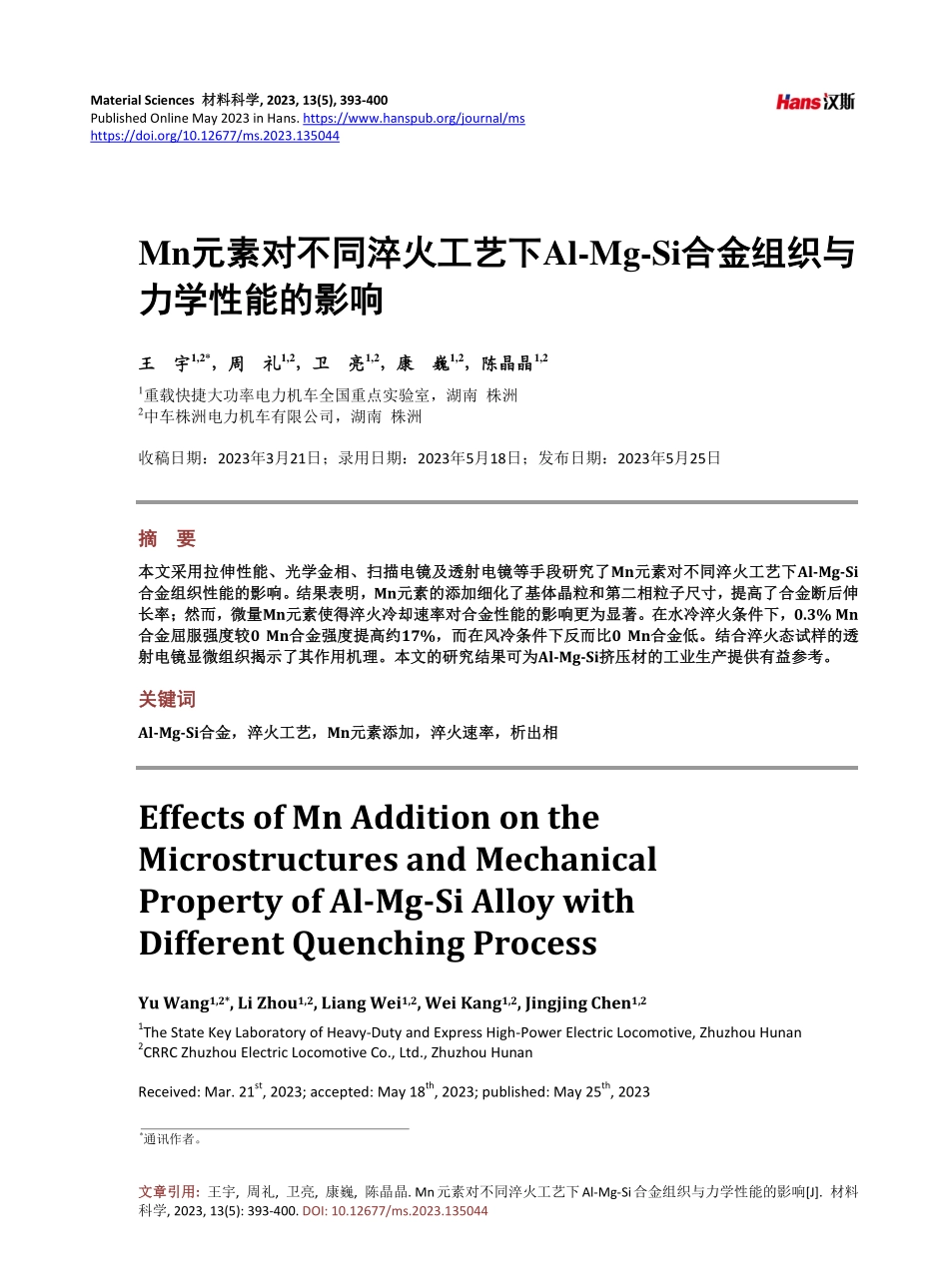

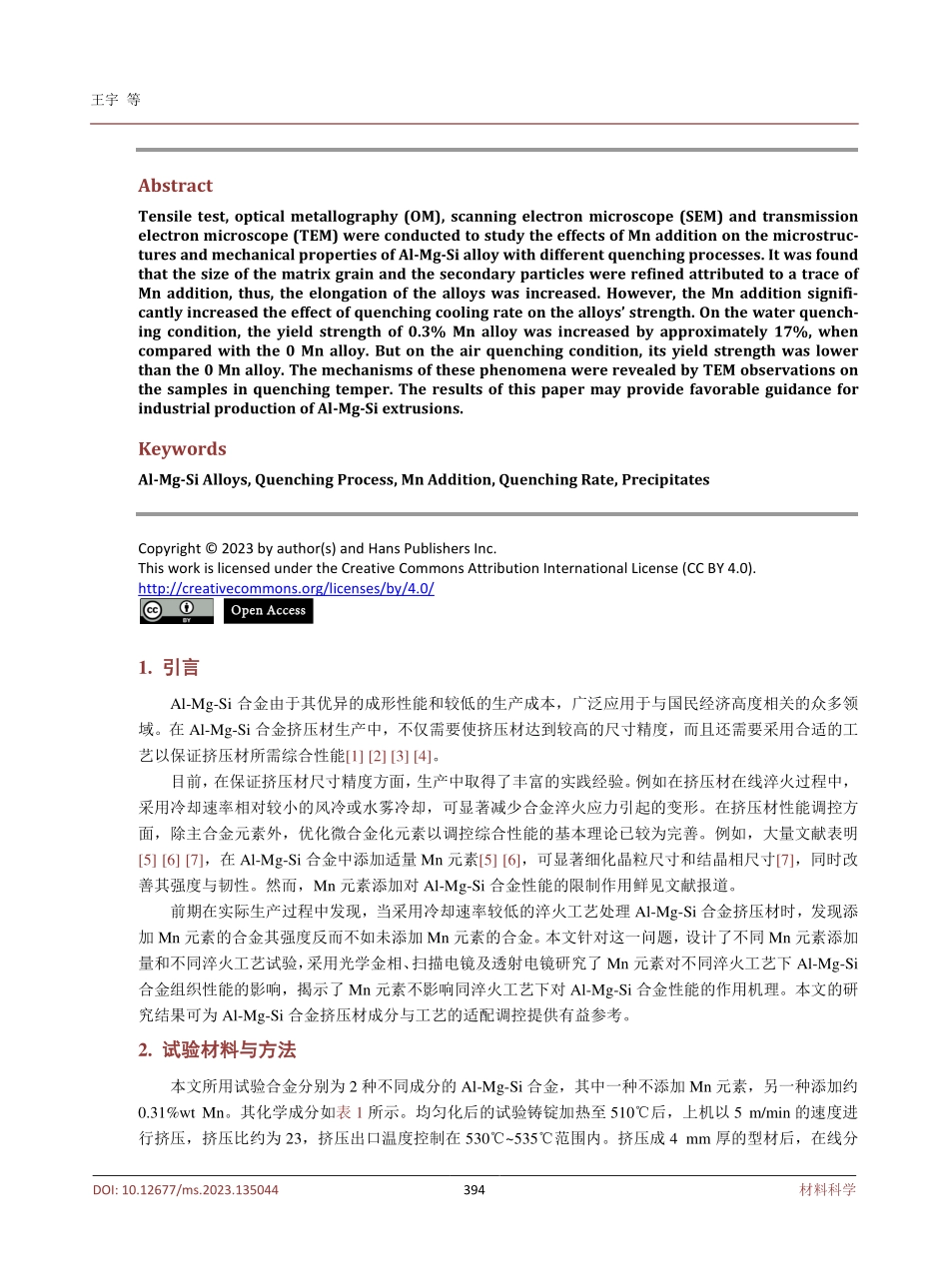

MaterialSciences材料科学,2023,13(5),393-400PublishedOnlineMay2023inHans.https://www.hanspub.org/journal/mshttps://doi.org/10.12677/ms.2023.135044文章引用:王宇,周礼,卫亮,康巍,陈晶晶.Mn元素对不同淬火工艺下Al-Mg-Si合金组织与力学性能的影响[J].材料科学,2023,13(5):393-400.DOI:10.12677/ms.2023.135044Mn元素对不同淬火工艺下Al-Mg-Si合金组织与力学性能的影响王宇1,2*,周礼1,2,卫亮1,2,康巍1,2,陈晶晶1,21重载快捷大功率电力机车全国重点实验室,湖南株洲2中车株洲电力机车有限公司,湖南株洲收稿日期:2023年3月21日;录用日期:2023年5月18日;发布日期:2023年5月25日摘要本文采用拉伸性能、光学金相、扫描电镜及透射电镜等手段研究了Mn元素对不同淬火工艺下Al-Mg-Si合金组织性能的影响。结果表明,Mn元素的添加细化了基体晶粒和第二相粒子尺寸,提高了合金断后伸长率;然而,微量Mn元素使得淬火冷却速率对合金性能的影响更为显著。在水冷淬火条件下,0.3%Mn合金屈服强度较0Mn合金强度提高约17%,而在风冷条件下反而比0Mn合金低。结合淬火态试样的透射电镜显微组织揭示了其作用机理。本文的研究结果可为Al-Mg-Si挤压材的工业生产提供有益参考。关键词Al-Mg-Si合金,淬火工艺,Mn元素添加,淬火速率,析出相EffectsofMnAdditionontheMicrostructuresandMechanicalPropertyofAl-Mg-SiAlloywithDifferentQuenchingProcessYuWang1,2*,LiZhou1,2,LiangWei1,2,WeiKang1,2,JingjingChen1,21TheStateKeyLaboratoryofHeavy-DutyandExpressHigh-PowerElectricLocomotive,ZhuzhouHunan2CRRCZhuzhouElectricLocomotiveCo.,Ltd.,ZhuzhouHunanReceived:Mar.21st,2023;accepted:May18th,2023;published:May25th,2023*通讯作者。王宇等DOI:10.12677/ms.2023.135044394材料科学AbstractTensiletest,opticalmetallography(OM),scanningelectronmicroscope(SEM)andtransmissionelectronmicroscope(TEM)wereconductedtostudytheeffectsofMnadditiononthemicrostruc-turesandmechanicalpropertiesofAl-Mg-Sialloywithdifferentquenchingprocesses.ItwasfoundthatthesizeofthematrixgrainandthesecondaryparticleswererefinedattributedtoatraceofMnaddition,thus,theelongationofthealloyswasincreased.However,theMnadditionsignifi-cantlyincreasedtheeffectofquenchingcoolingrateonthealloys’strength.Onthewaterquench-ingcondition,theyiel...