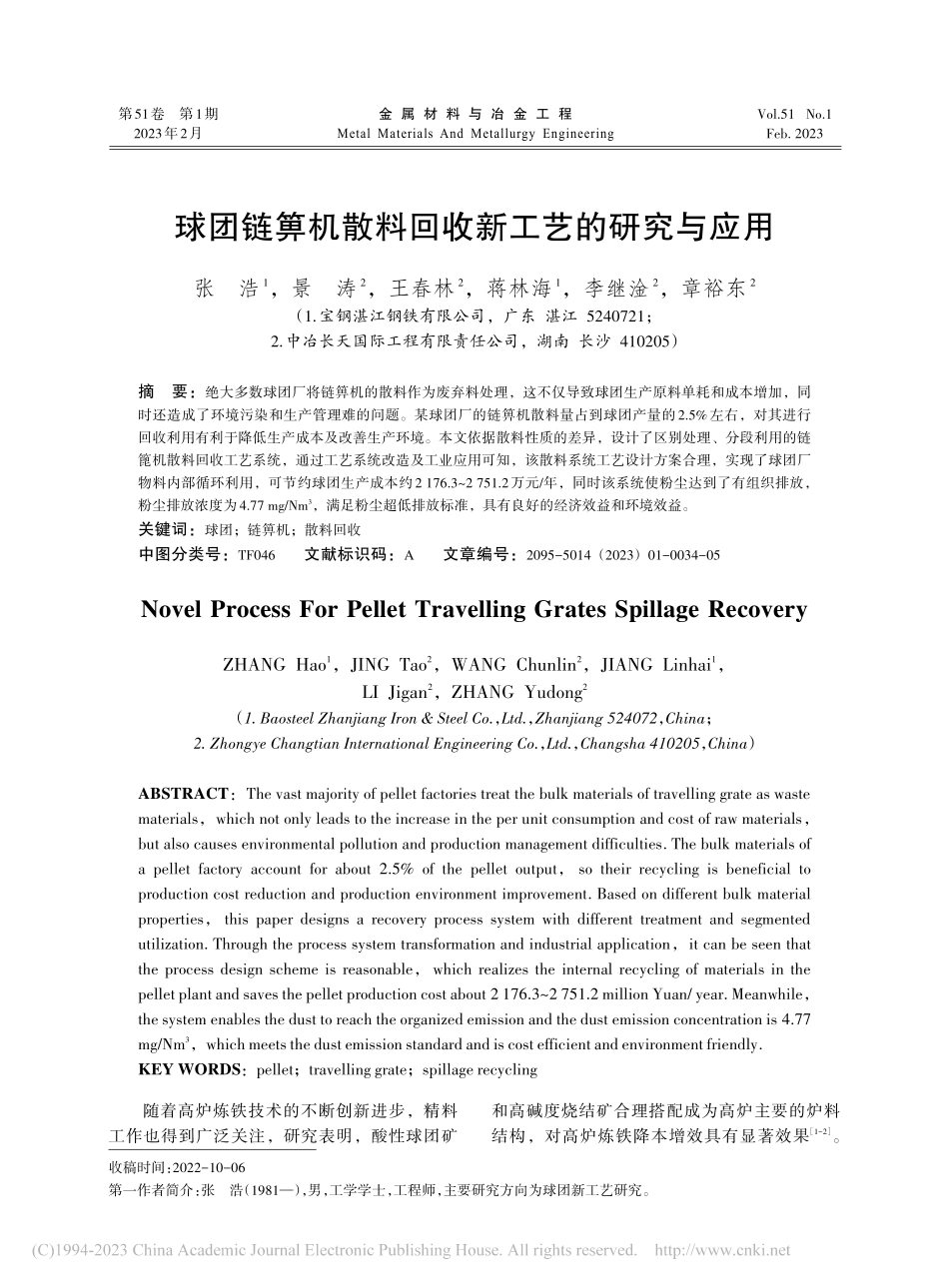

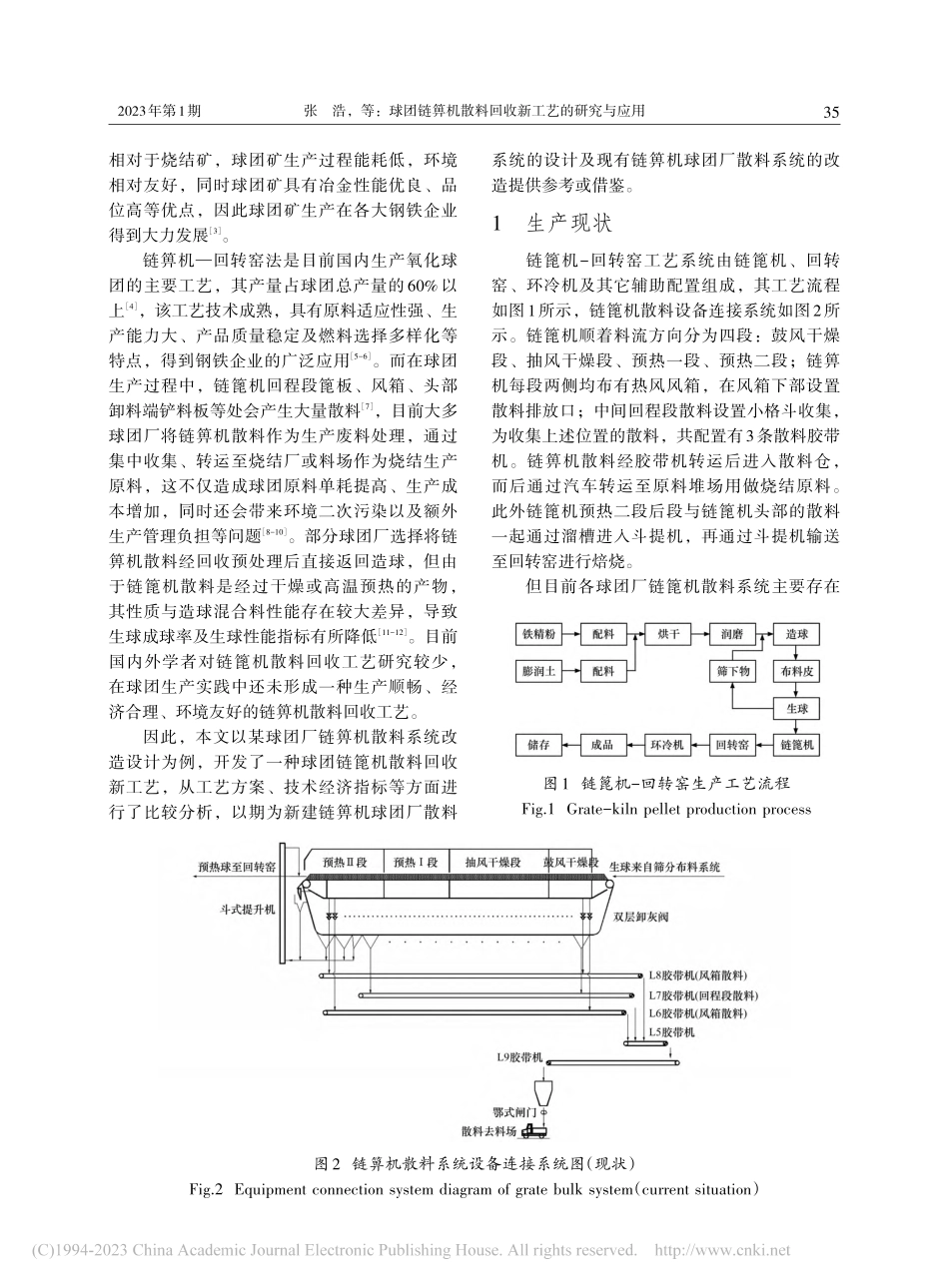

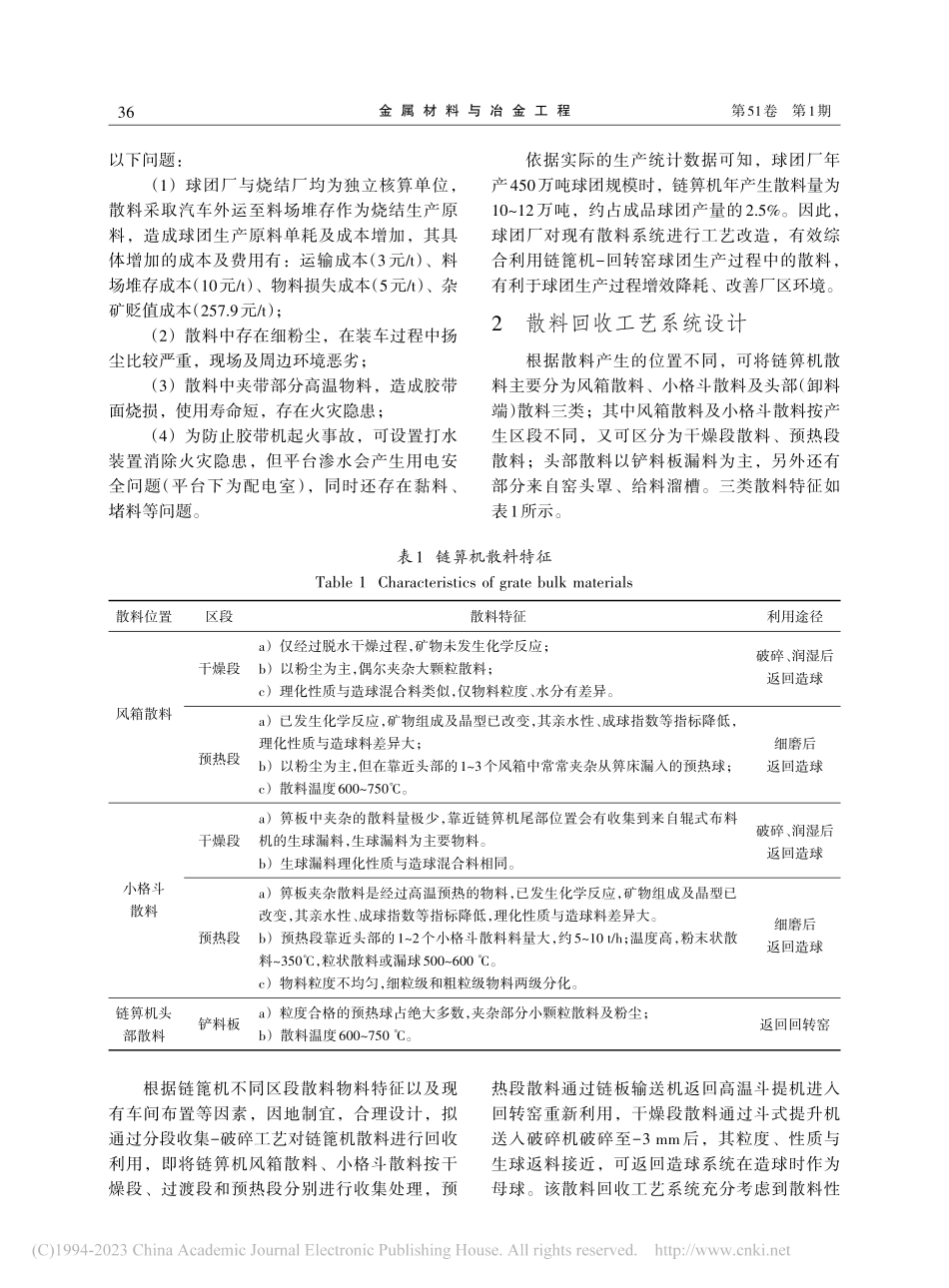

金属材料与冶金工程第51卷第1期球团链箅机散料回收新工艺的研究与应用张浩1,景涛2,王春林2,蒋林海1,李继淦2,章裕东2(1.宝钢湛江钢铁有限公司,广东湛江5240721;2.中冶长天国际工程有限责任公司,湖南长沙410205)摘要:绝大多数球团厂将链箅机的散料作为废弃料处理,这不仅导致球团生产原料单耗和成本增加,同时还造成了环境污染和生产管理难的问题。某球团厂的链箅机散料量占到球团产量的2.5%左右,对其进行回收利用有利于降低生产成本及改善生产环境。本文依据散料性质的差异,设计了区别处理、分段利用的链篦机散料回收工艺系统,通过工艺系统改造及工业应用可知,该散料系统工艺设计方案合理,实现了球团厂物料内部循环利用,可节约球团生产成本约2176.3~2751.2万元/年,同时该系统使粉尘达到了有组织排放,粉尘排放浓度为4.77mg/Nm3,满足粉尘超低排放标准,具有良好的经济效益和环境效益。关键词:球团;链箅机;散料回收中图分类号:TF046文献标识码:A文章编号:2095-5014(2023)01-0034-05NovelProcessForPelletTravellingGratesSpillageRecoveryZHANGHao1,JINGTao2,WANGChunlin2,JIANGLinhai1,LIJigan2,ZHANGYudong2(1.BaosteelZhanjiangIron&SteelCo.,Ltd.,Zhanjiang524072,China;2.ZhongyeChangtianInternationalEngineeringCo.,Ltd.,Changsha410205,China)ABSTRACT:Thevastmajorityofpelletfactoriestreatthebulkmaterialsoftravellinggrateaswastematerials,whichnotonlyleadstotheincreaseintheperunitconsumptionandcostofrawmaterials,butalsocausesenvironmentalpollutionandproductionmanagementdifficulties.Thebulkmaterialsofapelletfactoryaccountforabout2.5%ofthepelletoutput,sotheirrecyclingisbeneficialtoproductioncostreductionandproductionenvironmentimprovement.Basedondifferentbulkmaterialproperties,thispaperdesignsarecoveryprocesssystemwithdifferenttreatmentandsegmentedutilization.Throughtheprocesssystemtransformationandindustrialapplication,itcanbeseenthattheprocessdesignschemeisreasonable,whichrealizestheinternalrecyclingofmaterialsinthepelletplantandsavesthepelletproductioncostabout2176.3~2751.2millionYuan/year.Meanwhile,thesystemenablesthedusttoreachtheorganizedemissionandthedustemissionconcentrationis4.77mg/Nm3,whichmeetsthed...