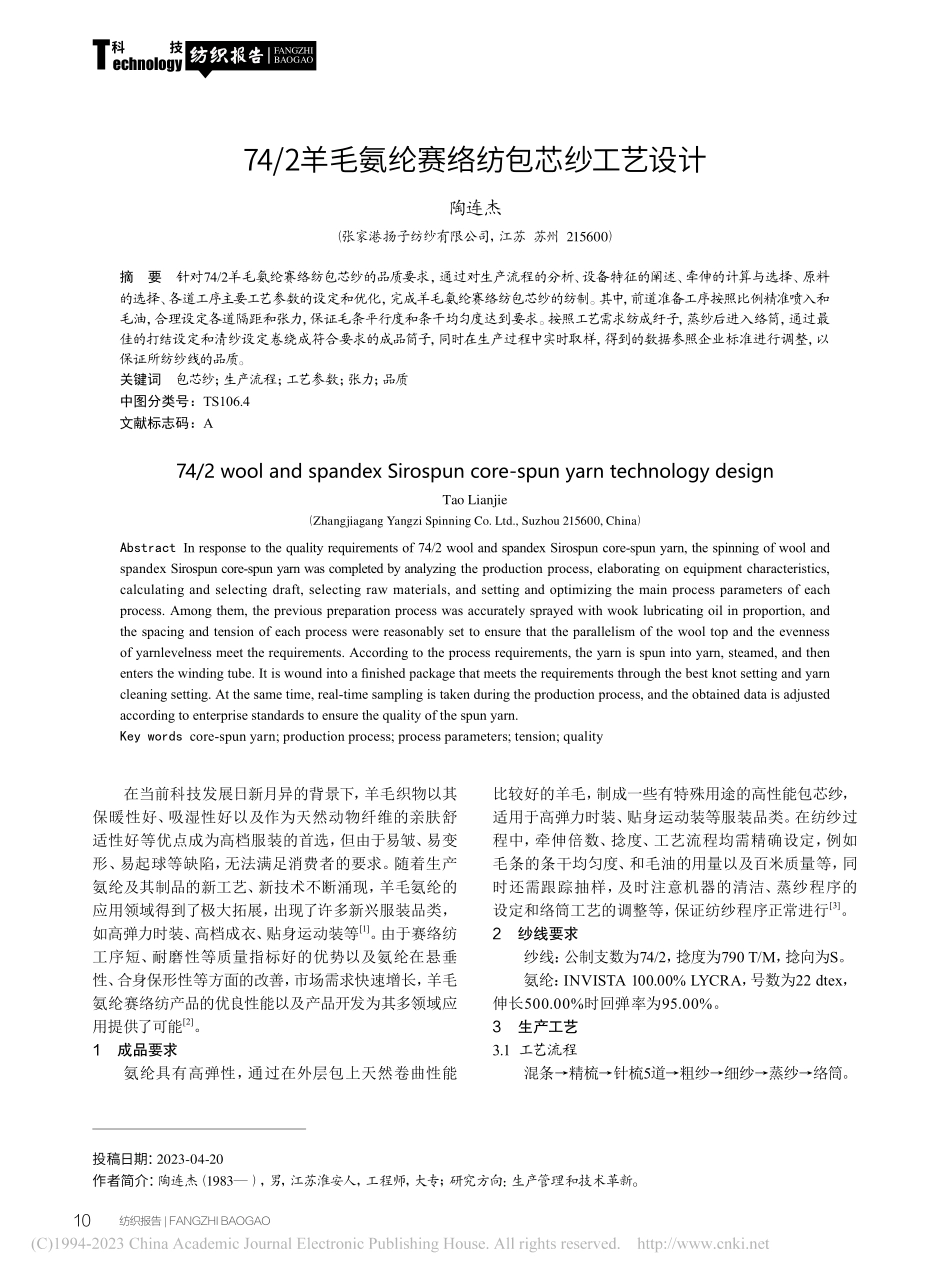

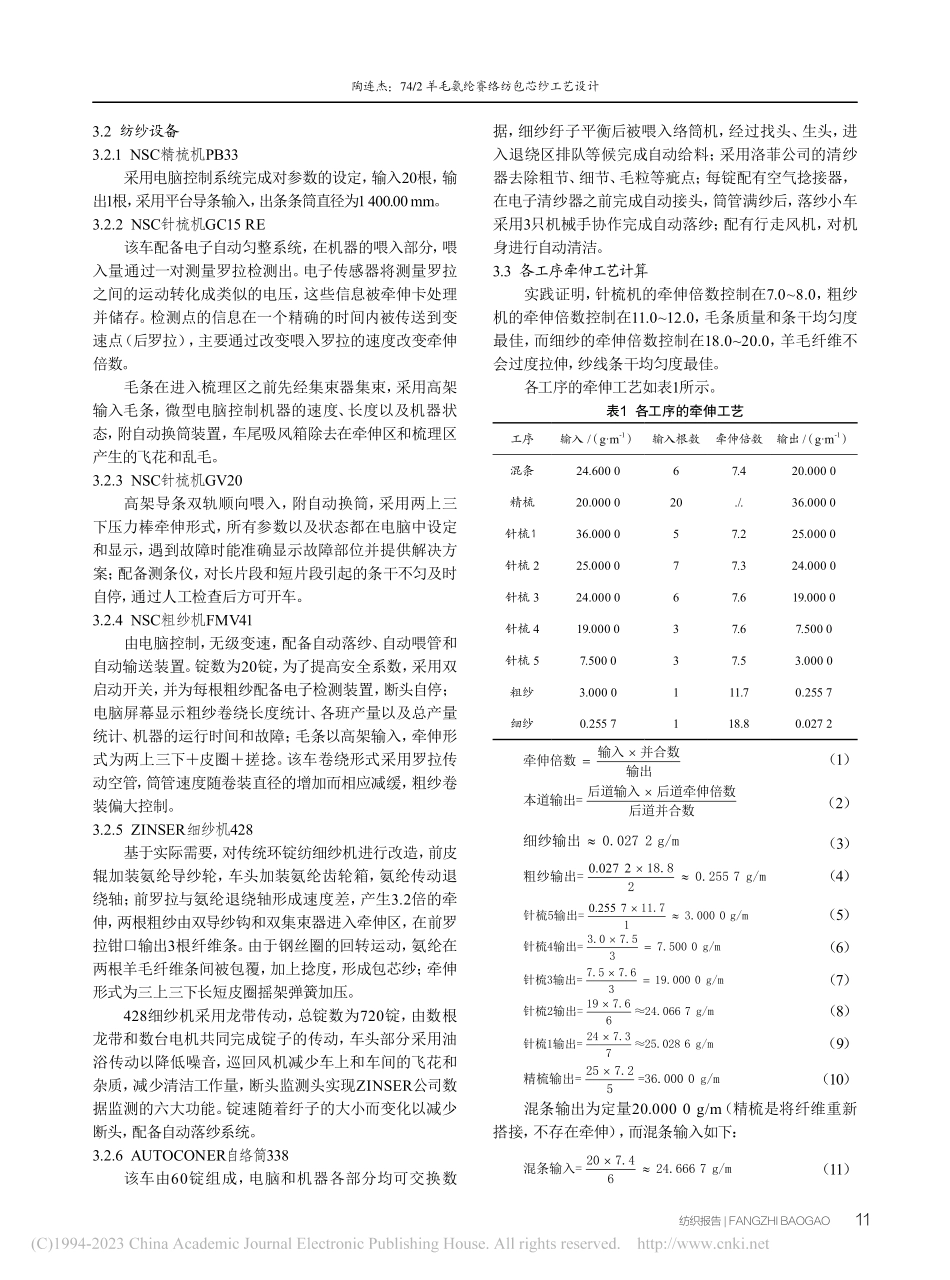

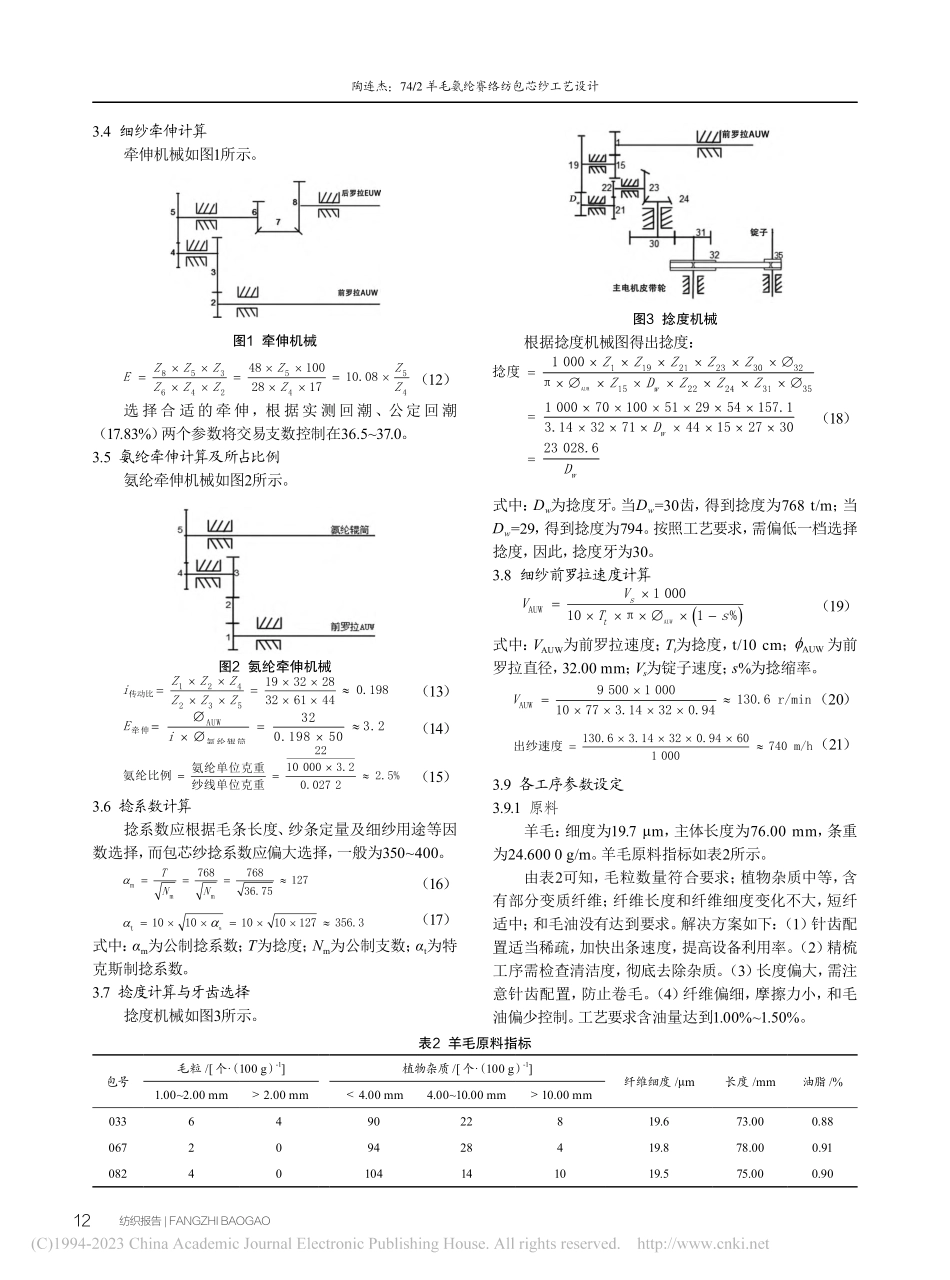

10纺织报告|FANGZHIBAOGAO在当前科技发展日新月异的背景下,羊毛织物以其保暖性好、吸湿性好以及作为天然动物纤维的亲肤舒适性好等优点成为高档服装的首选,但由于易皱、易变形、易起球等缺陷,无法满足消费者的要求。随着生产氨纶及其制品的新工艺、新技术不断涌现,羊毛氨纶的应用领域得到了极大拓展,出现了许多新兴服装品类,如高弹力时装、高档成衣、贴身运动装等[1]。由于赛络纺工序短、耐磨性等质量指标好的优势以及氨纶在悬垂性、合身保形性等方面的改善,市场需求快速增长,羊毛氨纶赛络纺产品的优良性能以及产品开发为其多领域应用提供了可能[2]。1成品要求氨纶具有高弹性,通过在外层包上天然卷曲性能74/2羊毛氨纶赛络纺包芯纱工艺设计陶连杰(张家港扬子纺纱有限公司,江苏苏州215600)74/2woolandspandexSirospuncore-spunyarntechnologydesignTaoLianjie(ZhangjiagangYangziSpinningCo.Ltd.,Suzhou215600,China)AbstractInresponsetothequalityrequirementsof74/2woolandspandexSirospuncore-spunyarn,thespinningofwoolandspandexSirospuncore-spunyarnwascompletedbyanalyzingtheproductionprocess,elaboratingonequipmentcharacteristics,calculatingandselectingdraft,selectingrawmaterials,andsettingandoptimizingthemainprocessparametersofeachprocess.Amongthem,thepreviouspreparationprocesswasaccuratelysprayedwithwooklubricatingoilinproportion,andthespacingandtensionofeachprocesswerereasonablysettoensurethattheparallelismofthewooltopandtheevennessofyarnlevelnessmeettherequirements.Accordingtotheprocessrequirements,theyarnisspunintoyarn,steamed,andthenentersthewindingtube.Itiswoundintoafinishedpackagethatmeetstherequirementsthroughthebestknotsettingandyarncleaningsetting.Atthesametime,real-timesamplingistakenduringtheproductionprocess,andtheobtaineddataisadjustedaccordingtoenterprisestandardstoensurethequalityofthespunyarn.Keywordscore-spunyarn;productionprocess;processparameters;tension;quality比较好的羊毛,制成一些有特殊用途的高性能包芯纱,适用于高弹力时装、贴身运动装等服装品类。在纺纱过程中,牵伸倍数、捻度、工艺流程均需精确设定,例如毛条的条干均匀度、和毛油的用量以及百米质量等,同时还需跟踪抽样,及时注意机器的清洁、蒸纱程序的设定和络...