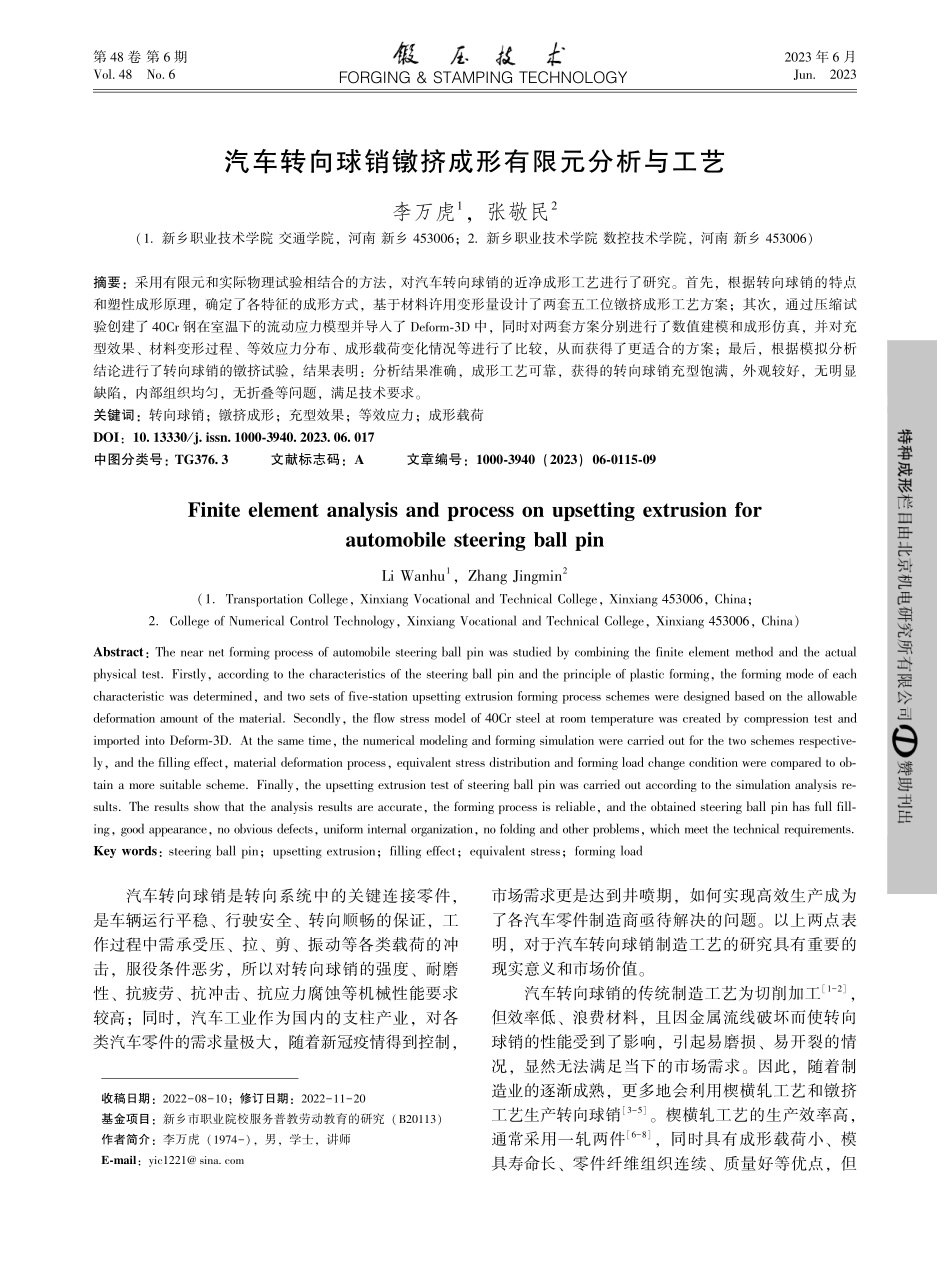

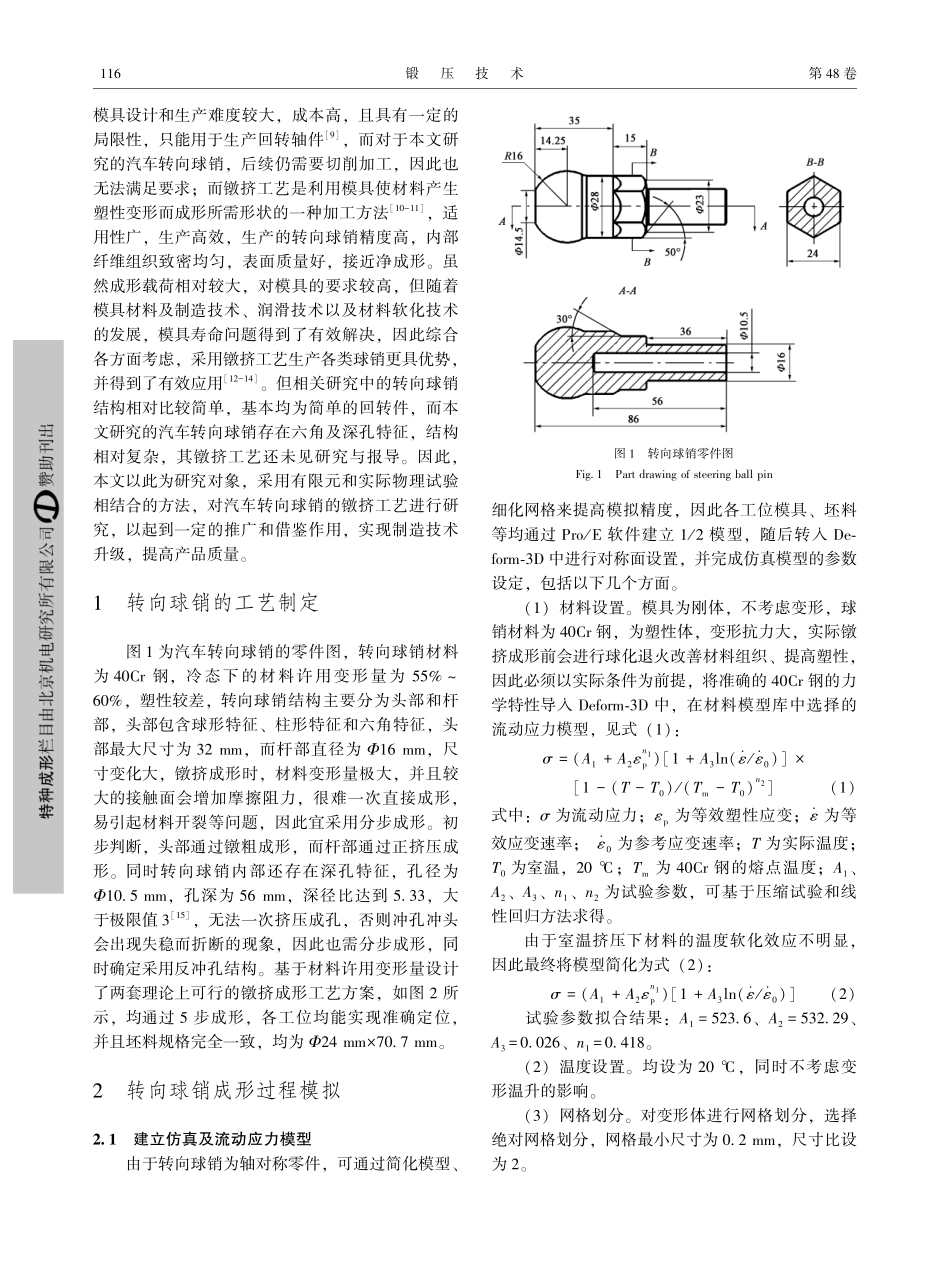

第48卷第6期Vol.48No.6FORGING&STAMPINGTECHNOLOGY2023年6月Jun.2023汽车转向球销镦挤成形有限元分析与工艺李万虎1,张敬民2(1.新乡职业技术学院交通学院,河南新乡453006;2.新乡职业技术学院数控技术学院,河南新乡453006)摘要:采用有限元和实际物理试验相结合的方法,对汽车转向球销的近净成形工艺进行了研究。首先,根据转向球销的特点和塑性成形原理,确定了各特征的成形方式,基于材料许用变形量设计了两套五工位镦挤成形工艺方案;其次,通过压缩试验创建了40Cr钢在室温下的流动应力模型并导入了Deform-3D中,同时对两套方案分别进行了数值建模和成形仿真,并对充型效果、材料变形过程、等效应力分布、成形载荷变化情况等进行了比较,从而获得了更适合的方案;最后,根据模拟分析结论进行了转向球销的镦挤试验,结果表明:分析结果准确,成形工艺可靠,获得的转向球销充型饱满,外观较好,无明显缺陷,内部组织均匀,无折叠等问题,满足技术要求。关键词:转向球销;镦挤成形;充型效果;等效应力;成形载荷DOI:10.13330/j.issn.1000-3940.2023.06.017中图分类号:TG376.3文献标志码:A文章编号:1000-3940(2023)06-0115-09FiniteelementanalysisandprocessonupsettingextrusionforautomobilesteeringballpinLiWanhu1,ZhangJingmin2(1.TransportationCollege,XinxiangVocationalandTechnicalCollege,Xinxiang453006,China;2.CollegeofNumericalControlTechnology,XinxiangVocationalandTechnicalCollege,Xinxiang453006,China)Abstract:Thenearnetformingprocessofautomobilesteeringballpinwasstudiedbycombiningthefiniteelementmethodandtheactualphysicaltest.Firstly,accordingtothecharacteristicsofthesteeringballpinandtheprincipleofplasticforming,theformingmodeofeachcharacteristicwasdetermined,andtwosetsoffive-stationupsettingextrusionformingprocessschemesweredesignedbasedontheallowabledeformationamountofthematerial.Secondly,theflowstressmodelof40CrsteelatroomtemperaturewascreatedbycompressiontestandimportedintoDeform-3D.Atthesametime,thenumericalmodelingandformingsimulationwerecarriedoutforthetwoschemesrespective-ly,andthefillingeffect,materialdeformationprocess,equivalentstressdistributionandformingloadchangeconditionwerecomparedtoob-tainamoresuitablescheme.Finally,theupsettingextrusiontestofsteeringballpi...