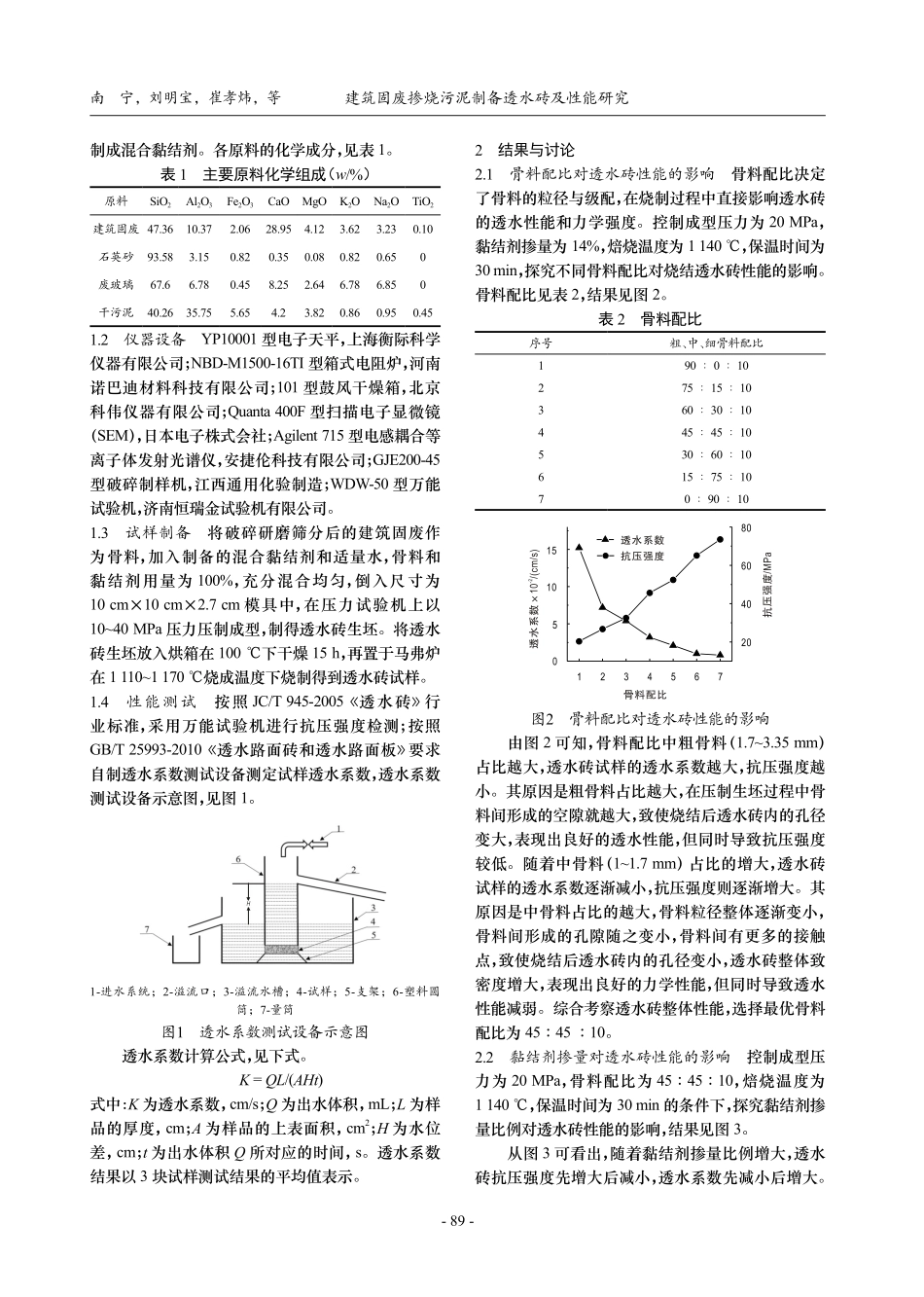

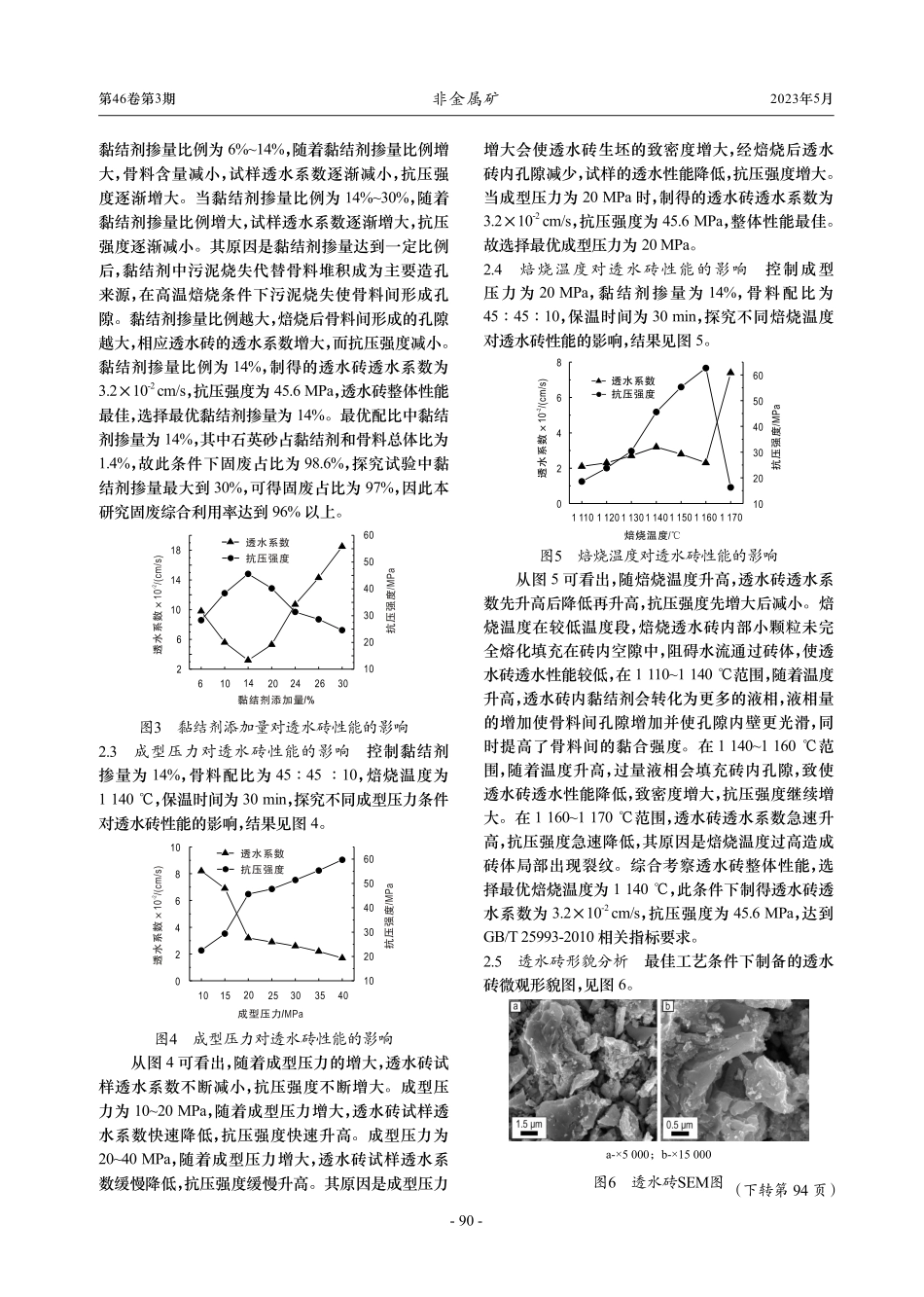

-88-第46卷第3期非金属矿Vol.46No.32023年5月Non-MetallicMinesMay,2023建筑固废掺烧污泥制备透水砖及性能研究南宁1,2,3刘明宝1,2,3*崔孝炜1,2,3李峰1,2,3*刘璇1,2,3王之宇1,2,3郑晓宇1(1商洛学院化学工程与现代材料学院,陕西商洛726000;2陕西省尾矿资源综合利用重点实验室,陕西商洛726000;3商洛学院商洛市石墨烯技术与应用研究中心,陕西商洛726000)摘要以废弃碎砖、废弃陶瓷砖和废弃混凝土块破碎的混合料为主要骨料,以污泥、石英砂和废玻璃混合料为黏结剂,研制环保型高性能透水砖。研究了骨料配比、黏结剂掺量、生坯成型压力、焙烧温度等因素对透水砖性能的影响。结果表明,当粗细骨料配比为45∶45∶10,黏结剂掺量为14%,成型压力为20MPa,焙烧温度为1140℃时,制得的透水砖性能最佳,透水系数为3.2×10-2cm/s,抗压强度为45.6MPa,透水系数和抗压强度达到透水砖GB/T25993-2010相关指标要求。关键词建筑固废;污泥;透水砖;透水系数;抗压强度中图分类号:TU522.1;X799.1文献标志码:A文章编号:1000-8098(2023)03-0088-04ResearchonPreparationandPerformanceofPermeableBrickUsingBuildingSolidWastewithSludgeNanNing1,2,3LiuMingbao1,2,3*CuiXiaowei1,2,3LiFeng1,2,3*LiuXuan1,2,3WangZhiyu1,2,3ZhengXiaoyu1(1CollegeofChemicalEngineeringandModernMaterials,ShangluoUniversity,Shangluo,Shaanxi726000;2ShaanxiKeyLaboratoryofCom-prehensiveUtilizationofTailingsResources,Shangluo,Shaanxi726000;3ResearchCentreofGrapheneTechnologyandApplication,ShangluoUniversity,Shangluo,Shaanxi726000)AbstractPermeablebrickwithenvironmentalprotectionandhighperformancewasdevelopedinthispaper.Themainaggregatewasmixtureofwastebrokenbrick,wasteceramicbrickandwasteconcreteblock,andthebinderwasmixtureofsludge,quartzsandandwasteglass.Theeffectsofaggregateratio,bindercontent,blankmoldingpressureandroastingtemperatureonthepropertiesofpermeablebrickwerestudied.Theresultsshowedthatthebestpermeablebrickcouldbepreparedwhentheratioofcoarseandfineaggregatewas45∶45∶10,bindercontentwas14%,moldingpressurewas20MPaandroastingtemperaturewas1140℃,anditspermeabilitycoefficientwas3.2×10-2cm/s,thecompressivestrengthwas45.6MPa.Thepermeabilitycoefficientandcompressivestrengthofpermeablebri...