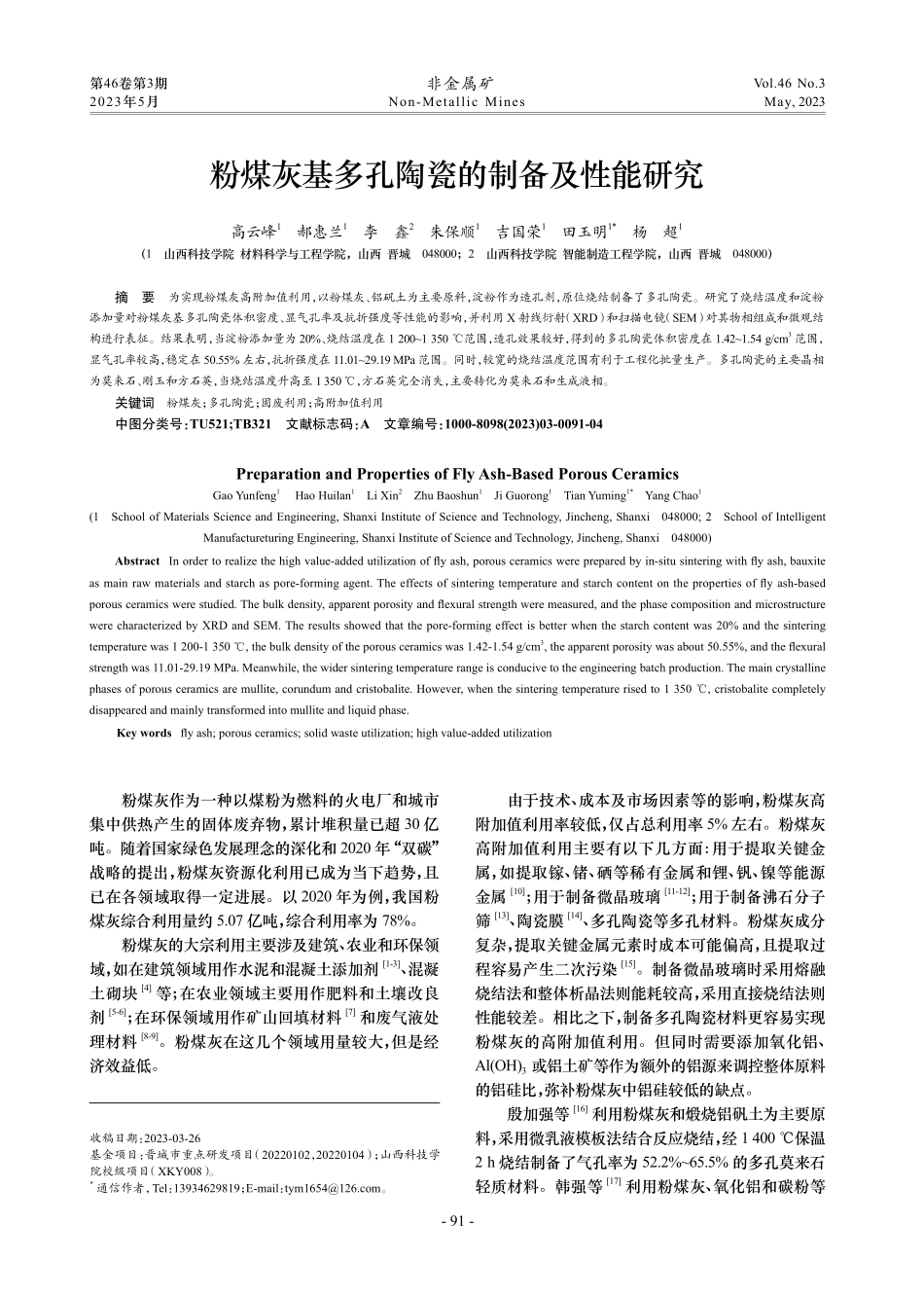

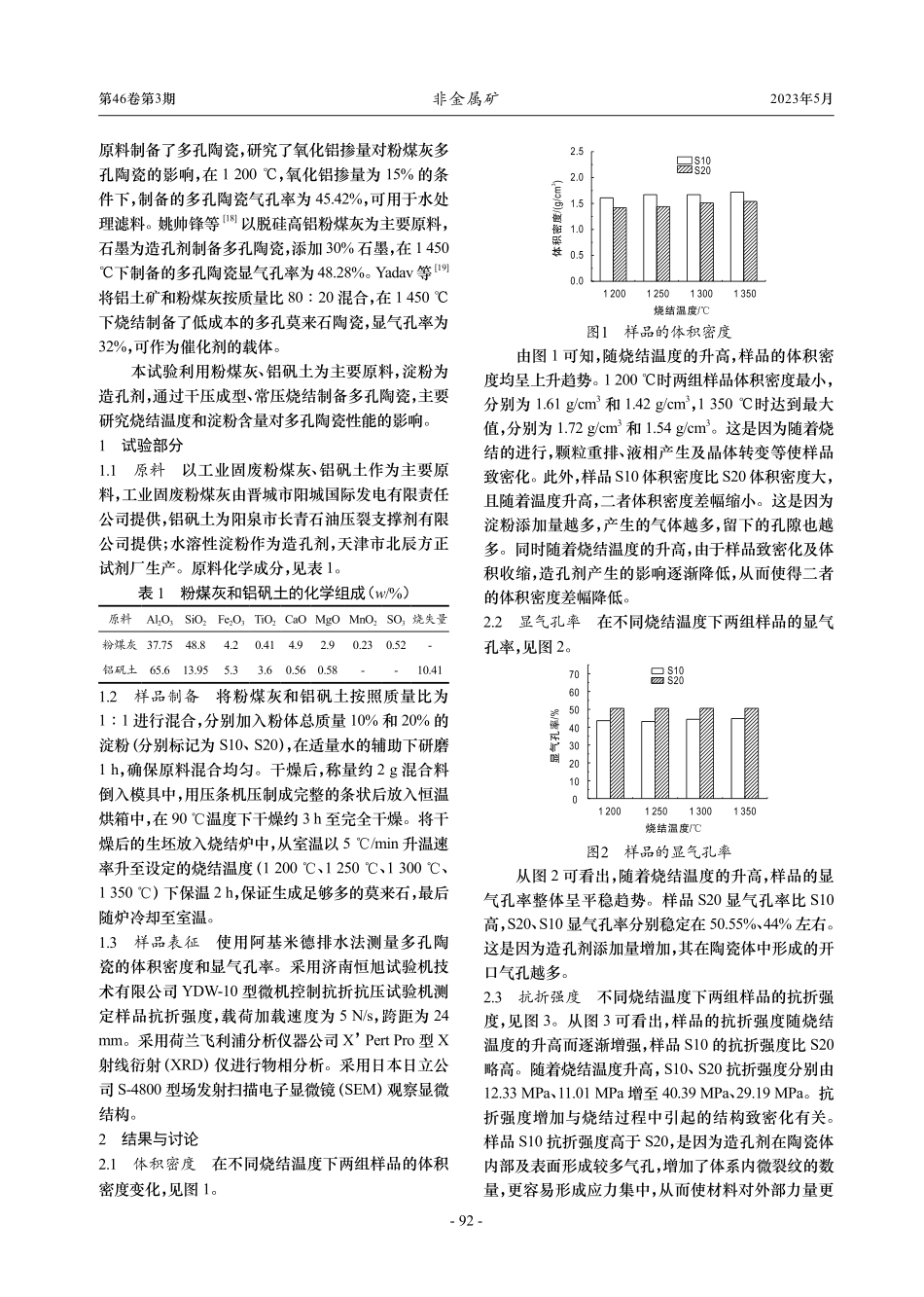

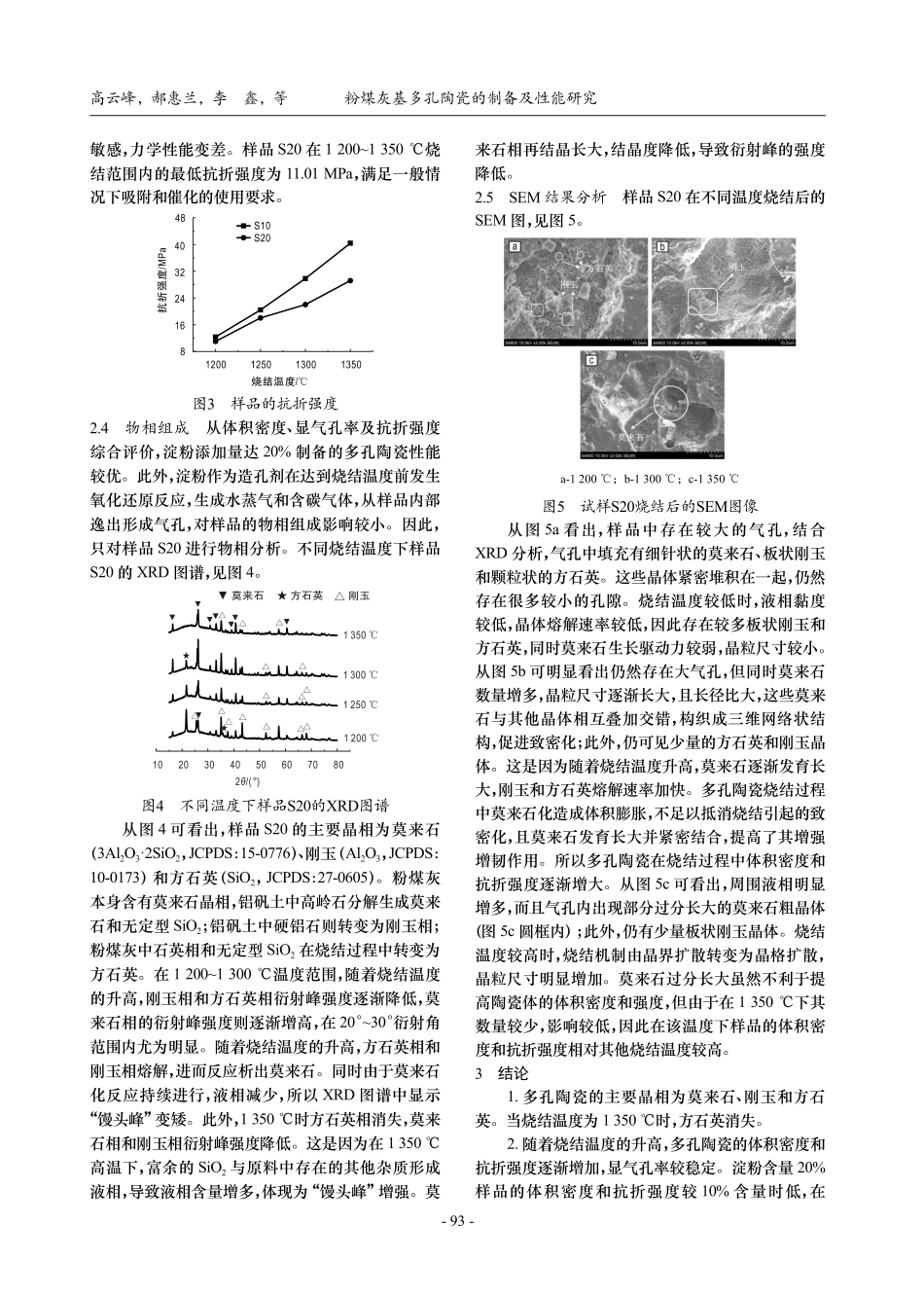

-91-第46卷第3期非金属矿Vol.46No.32023年5月Non-MetallicMinesMay,2023粉煤灰基多孔陶瓷的制备及性能研究高云峰1郝惠兰1李鑫2朱保顺1吉国荣1田玉明1*杨超1(1山西科技学院材料科学与工程学院,山西晋城048000;2山西科技学院智能制造工程学院,山西晋城048000)摘要为实现粉煤灰高附加值利用,以粉煤灰、铝矾土为主要原料,淀粉作为造孔剂,原位烧结制备了多孔陶瓷。研究了烧结温度和淀粉添加量对粉煤灰基多孔陶瓷体积密度、显气孔率及抗折强度等性能的影响,并利用X射线衍射(XRD)和扫描电镜(SEM)对其物相组成和微观结构进行表征。结果表明,当淀粉添加量为20%、烧结温度在1200~1350℃范围,造孔效果较好,得到的多孔陶瓷体积密度在1.42~1.54g/cm3范围,显气孔率较高,稳定在50.55%左右,抗折强度在11.01~29.19MPa范围。同时,较宽的烧结温度范围有利于工程化批量生产。多孔陶瓷的主要晶相为莫来石、刚玉和方石英,当烧结温度升高至1350℃,方石英完全消失,主要转化为莫来石和生成液相。关键词粉煤灰;多孔陶瓷;固废利用;高附加值利用中图分类号:TU521;TB321文献标志码:A文章编号:1000-8098(2023)03-0091-04PreparationandPropertiesofFlyAsh-BasedPorousCeramicsGaoYunfeng1HaoHuilan1LiXin2ZhuBaoshun1JiGuorong1TianYuming1*YangChao1(1SchoolofMaterialsScienceandEngineering,ShanxiInstituteofScienceandTechnology,Jincheng,Shanxi048000;2SchoolofIntelligentManufactureturingEngineering,ShanxiInstituteofScienceandTechnology,Jincheng,Shanxi048000)AbstractInordertorealizethehighvalue-addedutilizationofflyash,porousceramicswerepreparedbyin-situsinteringwithflyash,bauxiteasmainrawmaterialsandstarchaspore-formingagent.Theeffectsofsinteringtemperatureandstarchcontentonthepropertiesofflyash-basedporousceramicswerestudied.Thebulkdensity,apparentporosityandflexuralstrengthweremeasured,andthephasecompositionandmicrostructurewerecharacterizedbyXRDandSEM.Theresultsshowedthatthepore-formingeffectisbetterwhenthestarchcontentwas20%andthesinteringtemperaturewas1200-1350℃,thebulkdensityoftheporousceramicswas1.42-1.54g/cm3,theapparentporositywasabout50.55%,andtheflexuralstrengthwas11.01-29.19MPa.Meanwhile,thewidersinteringtemperaturerangeisconducivetotheengineeringbat...