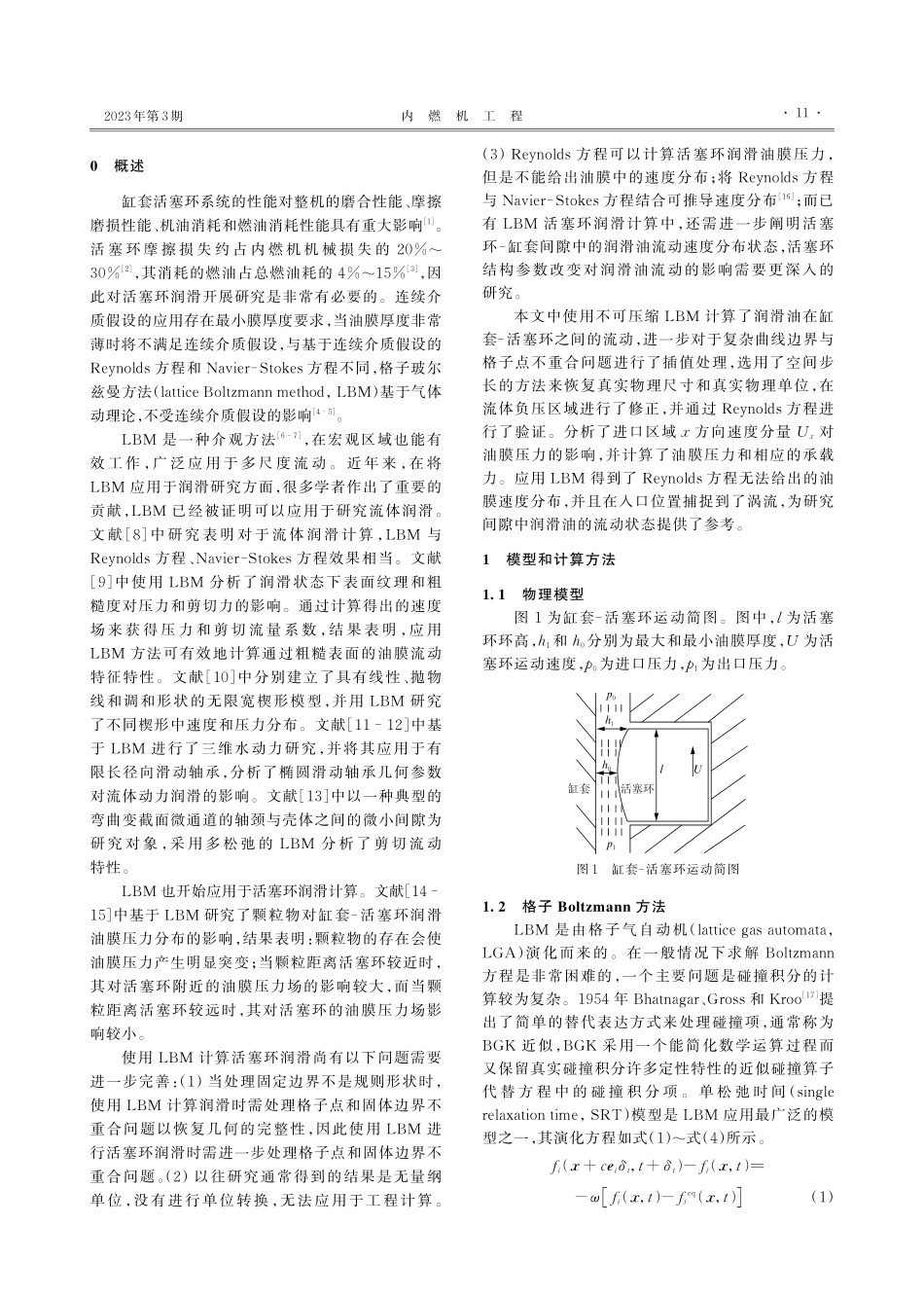

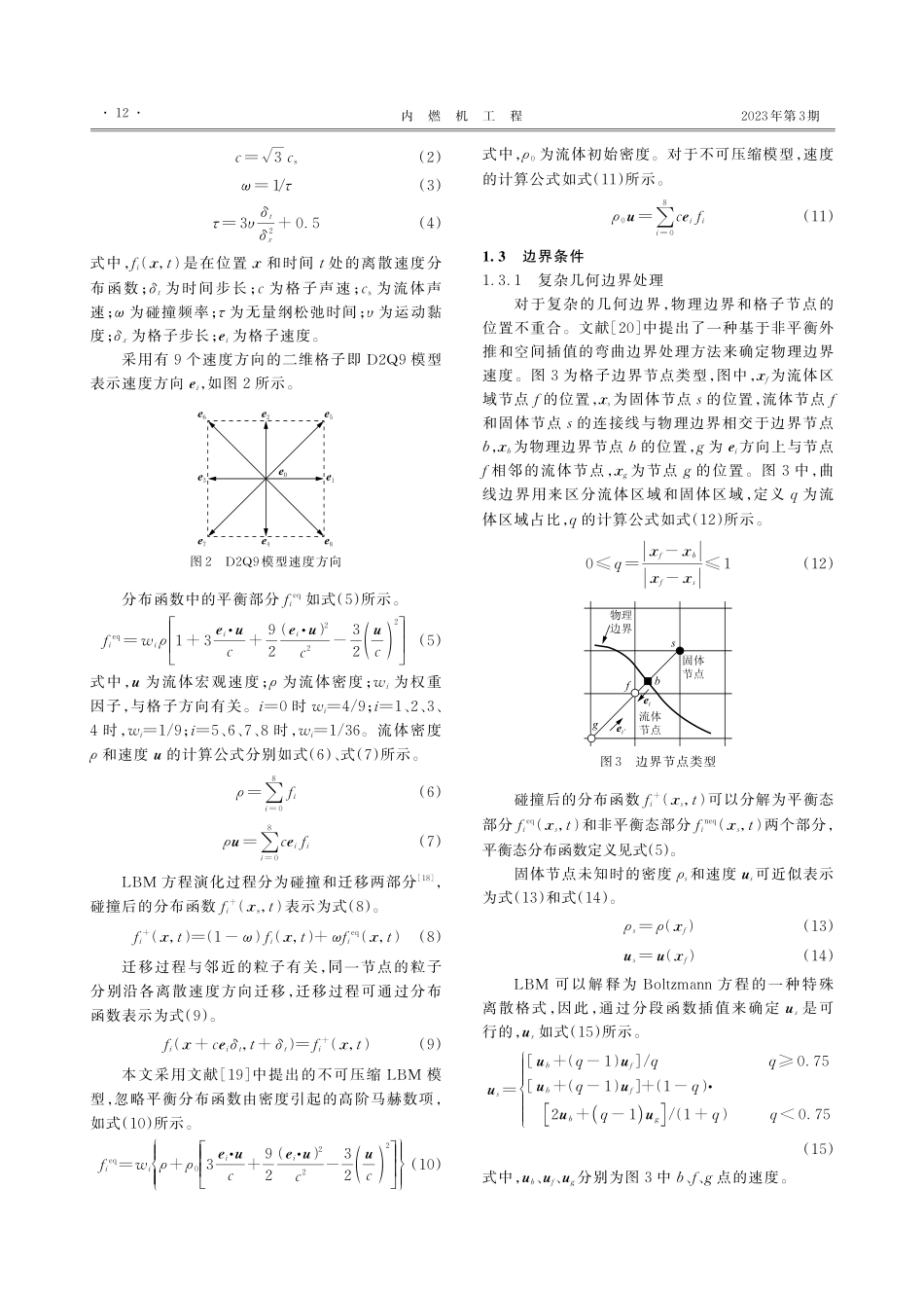

第44卷第3期2023年6月Vol.44No.3June2023内燃机工程ChineseInternalCombustionEngineEngineering基于格子Boltzmann方法的活塞环润滑和油膜流动研究房金伟,黎苏,刘晓日(河北工业大学能源与环境工程学院,天津300401)StudyonPistonRingLubricationandOilFilmFlowBasedonLatticeBoltzmannMethodFANGJinwei,LISu,LIUXiaori(SchoolofEnergyandEnvironmentalEngineering,HebeiUniversityofTechnology,Tianjin300401,China)Abstract:ThelubricationandflowofpistonringswerecalculatedwiththeincompressiblelatticeBoltzmannmethod(LBM).Thepistonringgeometricshapeandinterfacevelocityboundarywererestoredwiththemethodsofnon-equilibriumextrapolationandspatialinterpolation.ThefeasibilityofLBMwasverifiedbyReynoldsequation.Onthisbasis,threedifferentpistonringbarrelsurfaceprofileswereestablishedtostudytheinfluenceofdifferentpistonringbarrelsurfaceprofilesonlubricationandflow.Thevelocitydistributionandstreamlinediagraminthelubricationregionwereobtained.Theresultsshowthatunderthesameconditions,thepeakpressureandbearingcapacityincreasewiththeincreaseofbarrelsurfacedisplacement.Intheregionofgeometricconvergence,theproportionoffluidwithfastflowvelocityintheflowdirectionoflubricatingoilincreasesgradually.Thevortexandreversevelocitycomponentsarecapturedatthepistonringinletposition,andthereisatendencyforthevortexzonetoexpandasthebarrelsurfaceoffsetincreases.TheresultsshowthatitisfeasibletoapplyLBMtocalculatepistonringlubrication.摘要:使用不可压缩格子玻尔兹曼方法(latticeBoltzmannmethod,LBM)对活塞环进行润滑和流动计算,采用基于非平衡外推和空间插值的方法来重构活塞环几何形状和界面速度边界,通过Reynolds方程验证了LBM的可行性。在此基础上,建立了3种不同的活塞环桶面轮廓,研究了不同活塞环桶面轮廓对润滑和流动的影响,获得了润滑区域的速度分布和流线图。结果表明,在相同条件下,随着桶面偏移量的增加,峰值压力和承载力增加;在几何收敛区域内,润滑油沿流动方向流速快的流体占比逐渐增加;在活塞环入口位置捕捉到了涡流和反向速度分量的存在,随着桶面偏移的增大,涡流区有扩大的趋势。应用LBM计算活塞环润滑是可行的。关键词:活塞环;格子Bolt...