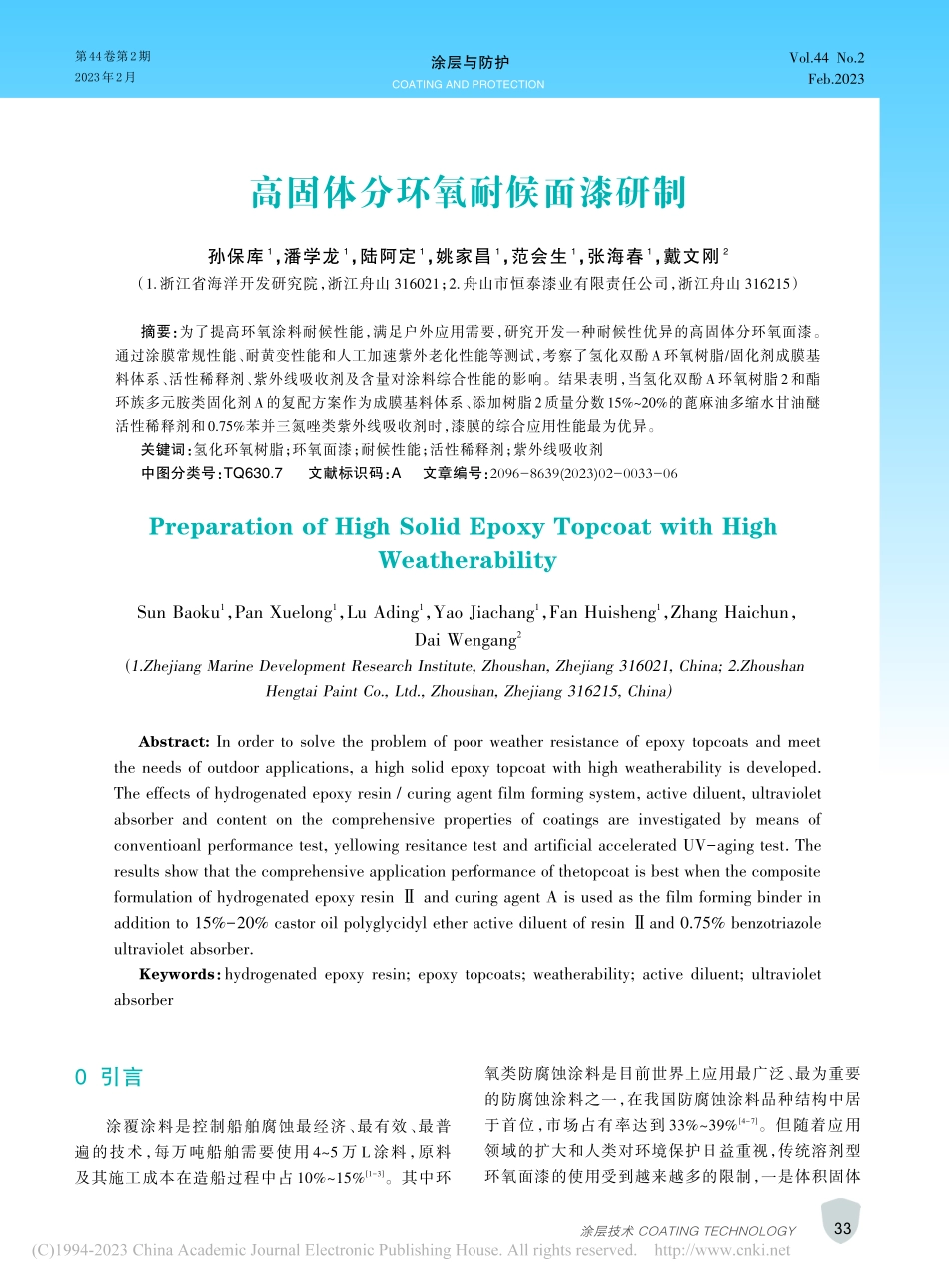

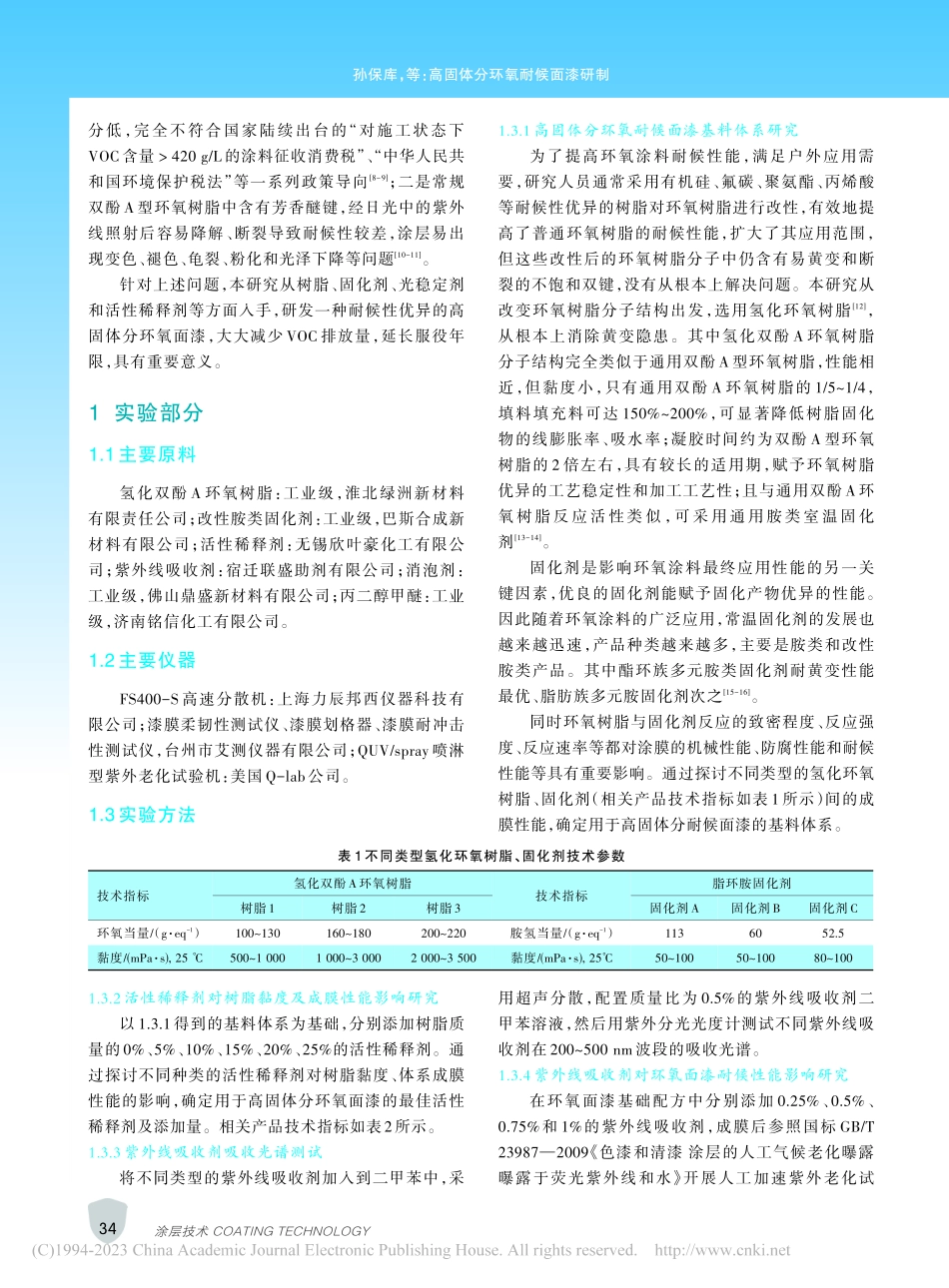

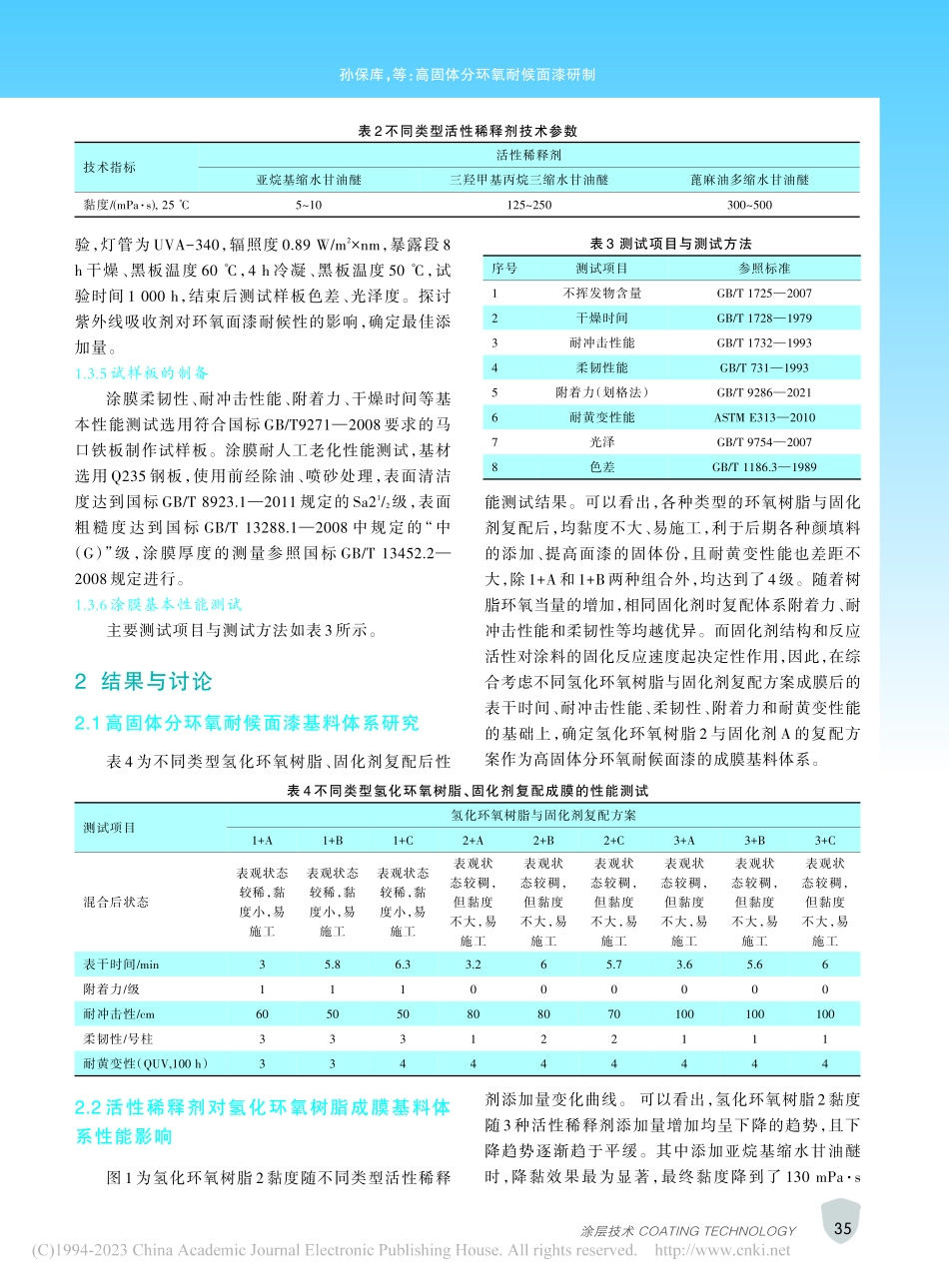

涂层技术COATINGTECHNOLOGY高固体分环氧耐候面漆研制孙保库1,潘学龙1,陆阿定1,姚家昌1,范会生1,张海春1,戴文刚2(1.浙江省海洋开发研究院,浙江舟山316021;2.舟山市恒泰漆业有限责任公司,浙江舟山316215)PreparationofHighSolidEpoxyTopcoatwithHighWeatherability摘要:为了提高环氧涂料耐候性能,满足户外应用需要,研究开发一种耐候性优异的高固体分环氧面漆。通过涂膜常规性能、耐黄变性能和人工加速紫外老化性能等测试,考察了氢化双酚A环氧树脂/固化剂成膜基料体系、活性稀释剂、紫外线吸收剂及含量对涂料综合性能的影响。结果表明,当氢化双酚A环氧树脂2和酯环族多元胺类固化剂A的复配方案作为成膜基料体系、添加树脂2质量分数15%~20%的蓖麻油多缩水甘油醚活性稀释剂和0.75%苯并三氮唑类紫外线吸收剂时,漆膜的综合应用性能最为优异。关键词:氢化环氧树脂;环氧面漆;耐候性能;活性稀释剂;紫外线吸收剂中图分类号:TQ630.7文献标识码:A文章编号:2096-8639(2023)02-0033-06SunBaoku1,PanXuelong1,LuAding1,YaoJiachang1,FanHuisheng1,ZhangHaichun,DaiWengang2(1.ZhejiangMarineDevelopmentResearchInstitute,Zhoushan,Zhejiang316021,China;2.ZhoushanHengtaiPaintCo.,Ltd.,Zhoushan,Zhejiang316215,China)0引言涂覆涂料是控制船舶腐蚀最经济、最有效、最普遍的技术,每万吨船舶需要使用4~5万L涂料,原料及其施工成本在造船过程中占10%~15%[1-3]。其中环氧类防腐蚀涂料是目前世界上应用最广泛、最为重要的防腐蚀涂料之一,在我国防腐蚀涂料品种结构中居于首位,市场占有率达到33%~39%[4-7]。但随着应用领域的扩大和人类对环境保护日益重视,传统溶剂型环氧面漆的使用受到越来越多的限制,一是体积固体Abstract:Inordertosolvetheproblemofpoorweatherresistanceofepoxytopcoatsandmeettheneedsofoutdoorapplications,ahighsolidepoxytopcoatwithhighweatherabilityisdeveloped.Theeffectsofhydrogenatedepoxyresin/curingagentfilmformingsystem,activediluent,ultravioletabsorberandcontentonthecomprehensivepropertiesofcoatingsareinvestigatedbymeansofconventioanlperformancetest,yellowingresitancetestandartificialacceleratedUV-agingtest.TheresultsshowthatthecomprehensiveapplicationperformanceofthetopcoatisbestwhenthecompositeformulationofhydrogenatedepoxyresinⅡandcuringagentAisusedasthefi...