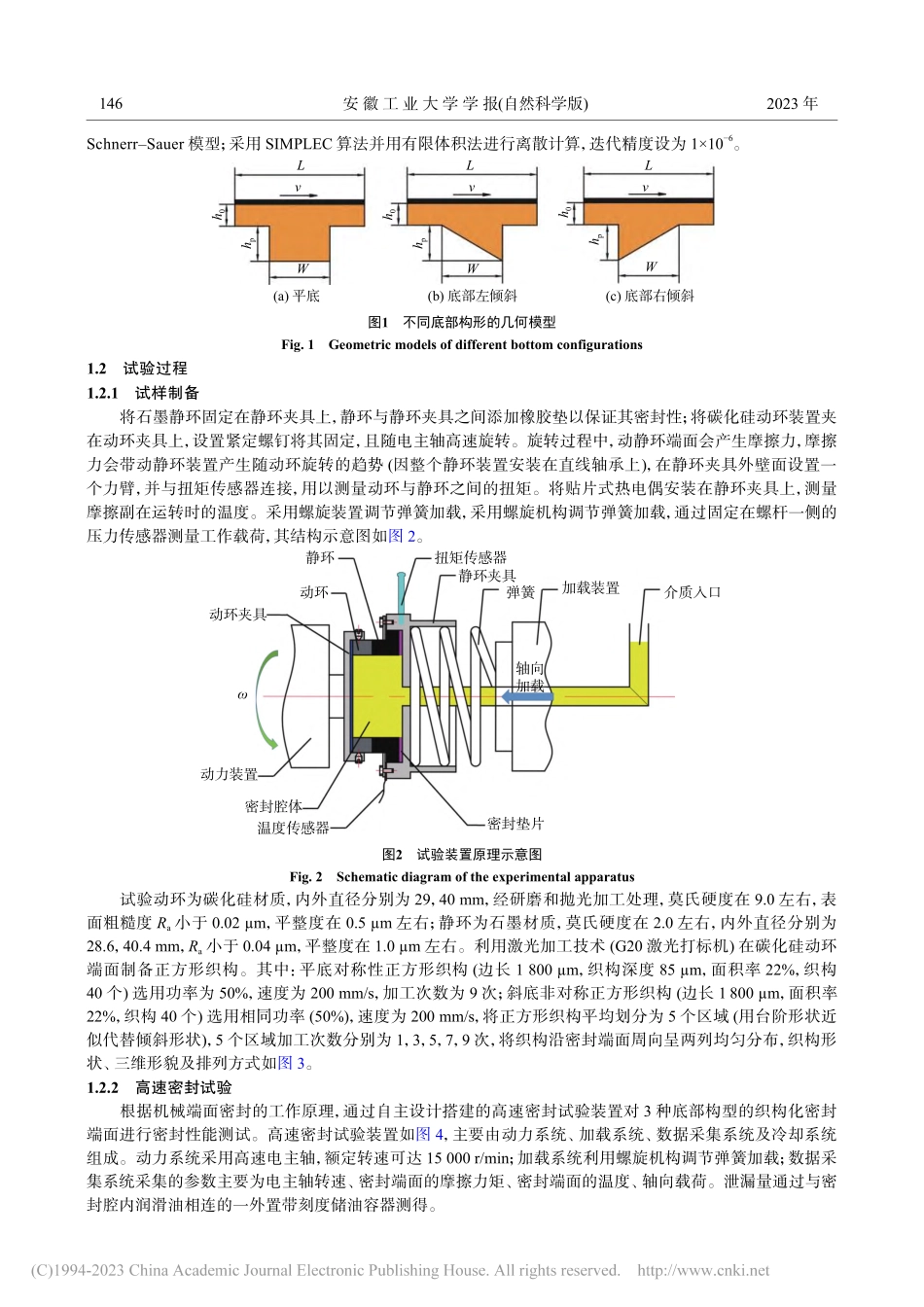

文章编号:1671-7872(2023)02-0144-07表面织构底部构形对液体润滑机械密封性能的影响史俊1a,1b,2,陈小亚1a,1b,2,李蒙1a,1b,王涛1a,1b,时礼平1a,1b,2(1.安徽工业大学a.机械工程学院,b.先进金属材料绿色制备与表面技术教育部重点实验室,安徽马鞍山243032;2.安徽工业大学芜湖技术创新研究院,安徽芜湖241002)摘要:表面织构负压区“空化”行为严重影响织构化密封端面整体密封性能。采用激光加工技术在碳化硅密封环端面制备出平底、左倾斜、右倾斜等3种底部形状的正方形凹坑织构,通过自主搭建的高速密封试验机开展试验,研究不同转速和轴向载荷条件下底部构形对端面摩擦系数、泄漏量及温度等密封性能参数的影响;利用Fluent17.0软件模拟分析3种底部构形截面的压力和流线分布。结果表明:随转速及轴向载荷的增大,底部左倾斜织构能显著减小端面摩擦系数和抑制泄漏,降低密封端面热量,有效改善机械密封性能;轴向载荷为110~140N,转速在7000r/min时,底面左倾斜织构可获得最佳的综合密封性能;底部左倾斜织构入口处的负压区面积显著减小,流体介质的“空化”行为得到有效抑制,织构区域内流线复杂而紊乱,回流更强烈,流体微动压效应更明显。关键词:织构底部构形;机械密封;流体动压;密封性能中图分类号:TH117.2文献标志码:Adoi:10.12415/j.issn.1671−7872.22314EffectofBottomConfigurationofSurfaceTextureonPerformanceofLiquidLubricatedMechanicalSealsSHIJun1a,1b,2,CHENXiaoya1a,1b,2,LIMeng1a,1b,WANGTao1a,1b,SHILiping1a,1b,2(1.a.SchoolofMechanicalEngineering,b.KeyLaboratoryofGreenPreparationandSurfaceTechnologyofAdvancedMetalMaterials,MinistryofEducation,AnhuiUniversityofTechnology,Maanshan243032,China;2.WuhuInstituteofTechnologyInnovation,AnhuiUniversityofTechnology,Wuhu241002,China)Abstract:The“cavitation”behaviorinthenegativepressureareaofthesurfacetextureseriouslyaffectstheoverallsealingperformanceofthetexturedsealface.Threesquarepittextureswithflatbottom,lefttiltandrighttilt,werepreparedontheendfaceofsiliconcarbidesealingringbylaserprocessingtechnology.Theeffectsofthebottomconfigurationsonsealingperformanceparameterssuchasendfrictioncoefficient,leakageandtemperatureandotherunderdifferentrotationalspeedsandaxialloadswerestudiedbyusingtheself-develop...