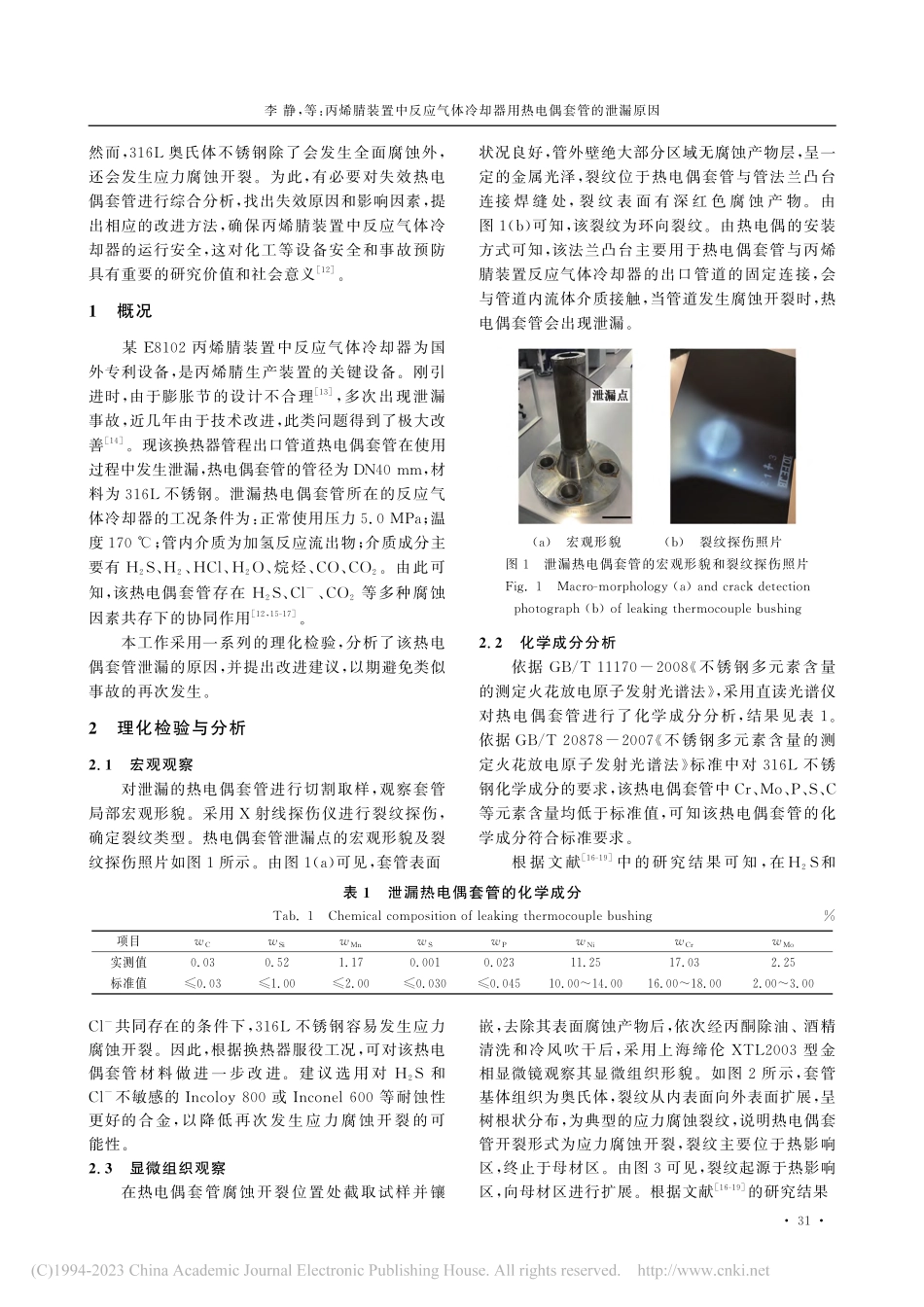

DOI:10.11973/fsyfh-202212005丙烯腈装置中反应气体冷却器用热电偶套管的泄漏原因李静1,2,刘文娟3,师红旗4(1.浙江大学化学工程与生物工程学院生物质化工教育部重点实验室,杭州310027;2.浙江大学衢州研究院,衢州324000;3.南京工业大学材料科学与工程学院,南京211816;4.宿迁学院信息工程学院,宿迁223800)摘要:某丙烯腈装置反应气体冷却器热电偶套管在使用过程中发生泄漏。采用宏观观察、化学成分分析、显微组织观察、显微硬度测试、扫描电镜和能谱分析等方法,分析了该热电偶套管泄漏的原因。结果表明:该热电偶套管的开裂形式为应力腐蚀开裂,其泄漏的主要原因是套管热影响区和母材区的表面状态和显微组织差异产生应力,在硫化氢和氯化物共存的环境中,在热影响区优先形成应力腐蚀裂纹,裂纹沿着晶界向母材扩展,从而在套管与法兰凸台的焊缝连接处发生开裂,最终导致热电偶套管在使用过程中发生泄漏。关键词:丙烯腈装置;热电偶套管;应力腐蚀开裂;316L不锈钢中图分类号:TG174文献标志码:B文章编号:1005-748X(2022)12-0030-05LeakageReasonofThermocoupleBushinginReactiveGasCoolerinAcrylonitrilePlantLIJing1,2,LIUWenjuan3,SHIHongqi4(1.KeyLaboratoryofBiomassChemicalEngineeringofMinistryofEducation,CollegeofChemicalandBiologicalEngineering,ZhejiangUniversity,Hangzhou310027,China;2.InstituteofZhejiangUniversity-Quzhou,Quzhou324000,China;3.CollegeofMaterialsScienceandEngineering,NanjingTechUniversity,Nanjing211816,China;4.SchoolofInformationEngineering,SuqianUniversity,Suqian223800,China)Abstract:Thethermocouplebushingofreactiongascoolerinanacrylonitrileplantleakedduringuse.Thecausesoftheleakagewereanalyzedbymeansofmacroscopicobservation,chemicalcompositionanalysis,microstructureobservation,microhardnesstest,scanningelectronmicroscopyandenergydispersivespectroscopy.Theresultsshowedthatthecrackingmodeofthethermocouplebushingwasstresscorrosioncracking.Themainreasonofitsleakagewasthedifferenceofsurfacestateandmicrostructurebetweenheataffectedzoneandbasemetalzoneofthermocouplebushingproducedstress,whichledtotheformationofstresscorrosioncracksintheheataffectedzonepreferentially.Intheenvironmentwherehydrogensulfideandchloridecoexisted.Thecrackspropagatedalongthegra...