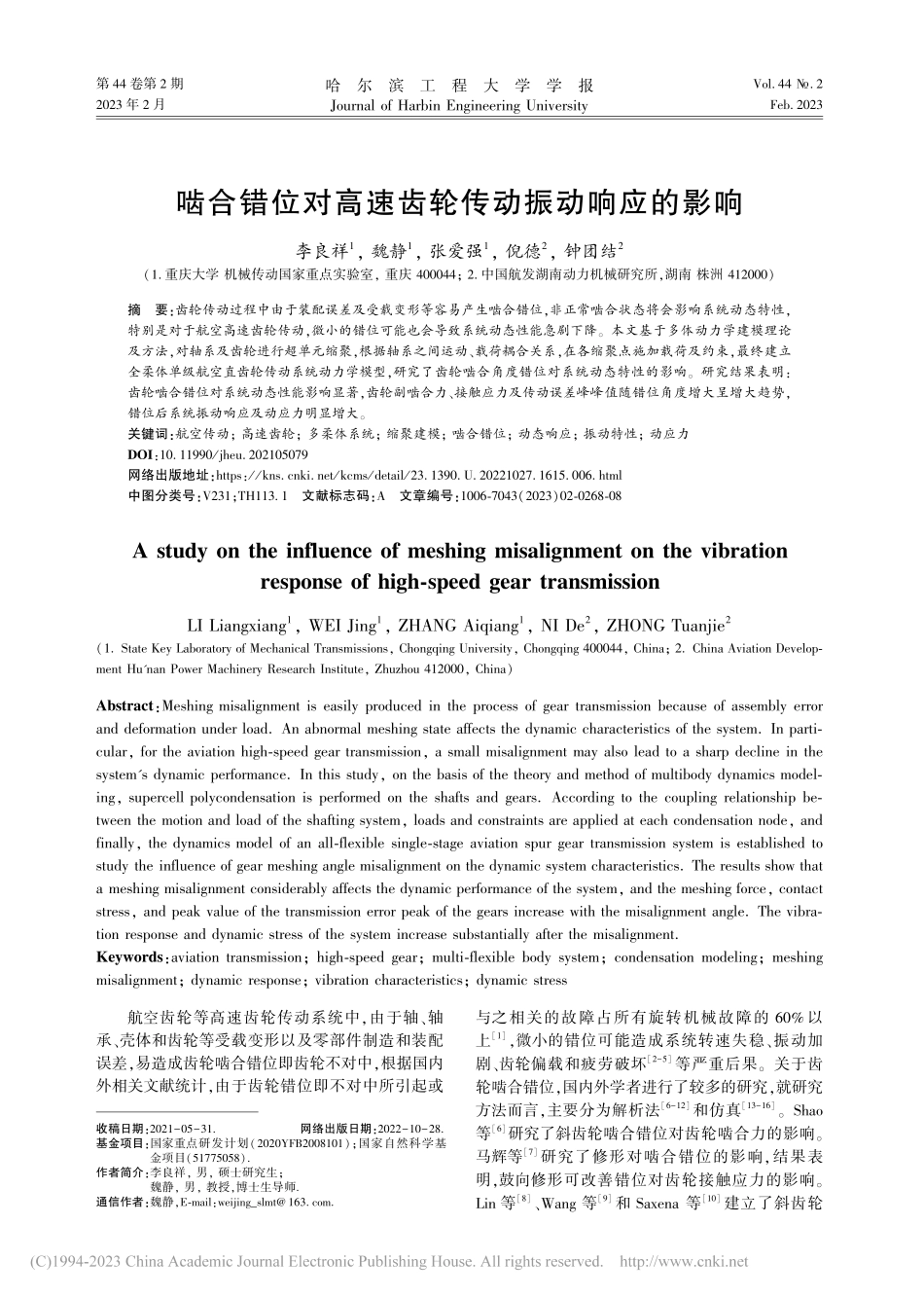

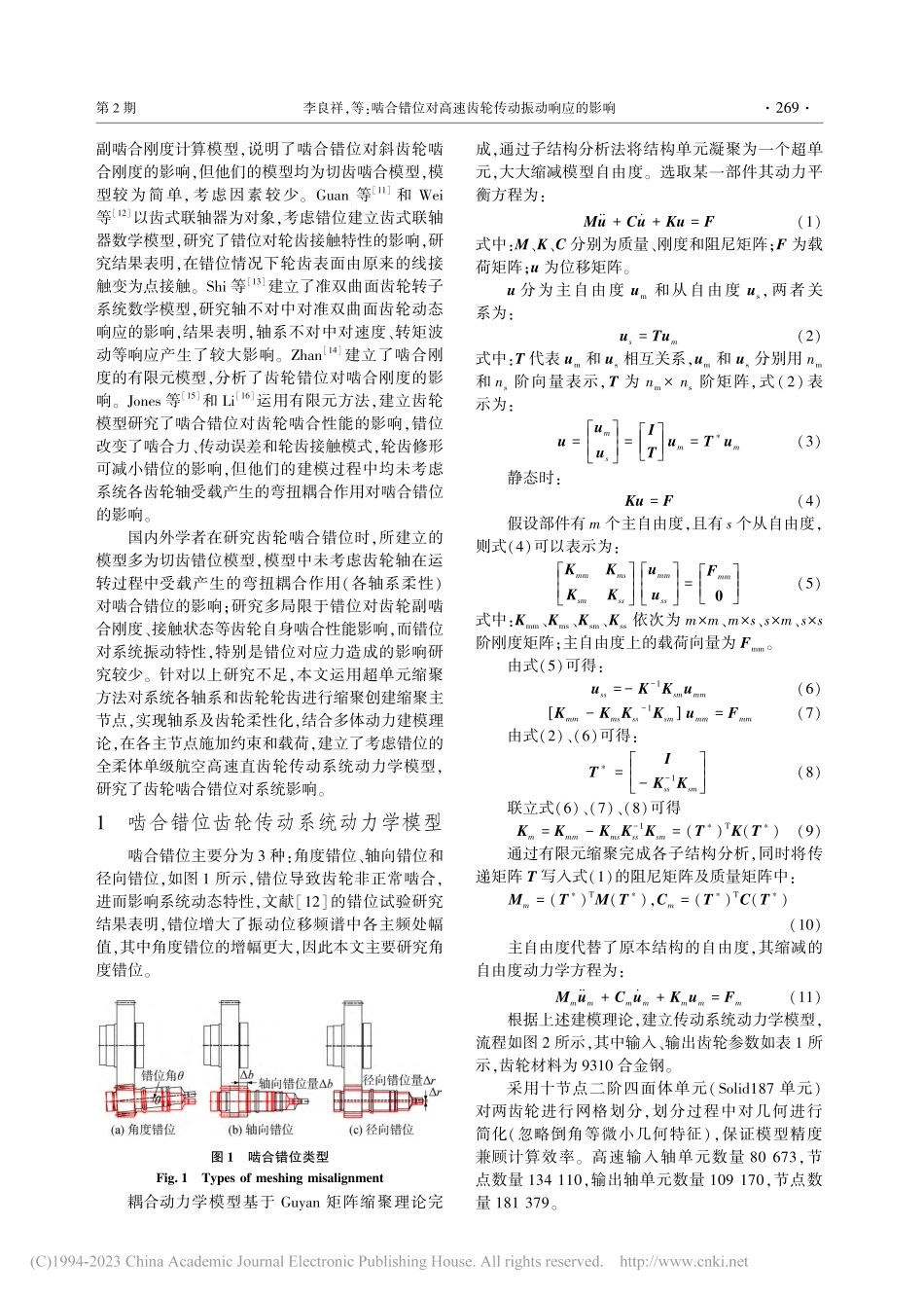

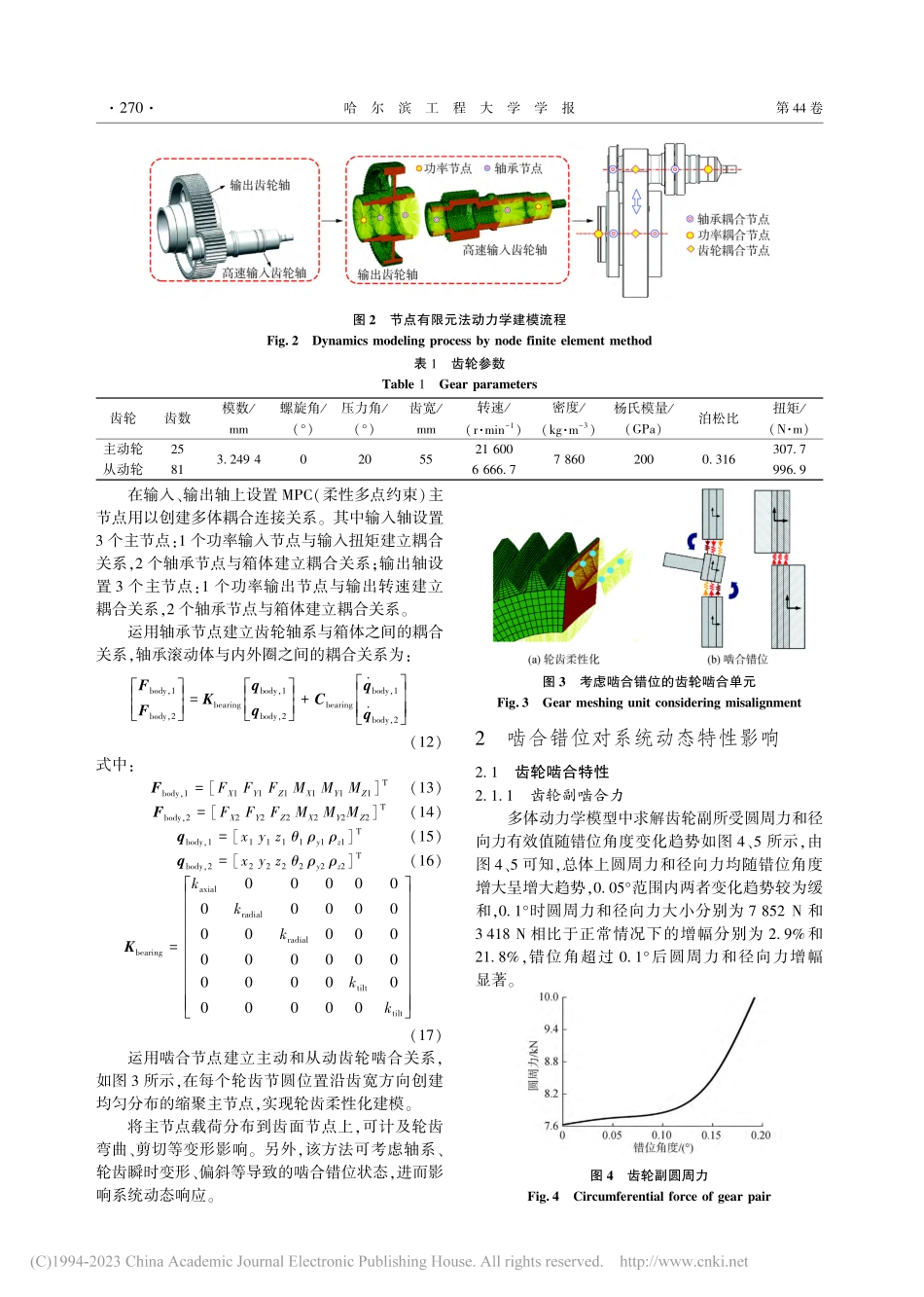

第44卷第2期2023年2月哈尔滨工程大学学报JournalofHarbinEngineeringUniversityVol.44№.2Feb.2023啮合错位对高速齿轮传动振动响应的影响李良祥1,魏静1,张爱强1,倪德2,钟团结2(1.重庆大学机械传动国家重点实验室,重庆400044;2.中国航发湖南动力机械研究所,湖南株洲412000)摘要:齿轮传动过程中由于装配误差及受载变形等容易产生啮合错位,非正常啮合状态将会影响系统动态特性,特别是对于航空高速齿轮传动,微小的错位可能也会导致系统动态性能急剧下降。本文基于多体动力学建模理论及方法,对轴系及齿轮进行超单元缩聚,根据轴系之间运动、载荷耦合关系,在各缩聚点施加载荷及约束,最终建立全柔体单级航空直齿轮传动系统动力学模型,研究了齿轮啮合角度错位对系统动态特性的影响。研究结果表明:齿轮啮合错位对系统动态性能影响显著,齿轮副啮合力、接触应力及传动误差峰峰值随错位角度增大呈增大趋势,错位后系统振动响应及动应力明显增大。关键词:航空传动;高速齿轮;多柔体系统;缩聚建模;啮合错位;动态响应;振动特性;动应力DOI:10.11990/jheu.202105079网络出版地址:https://kns.cnki.net/kcms/detail/23.1390.U.20221027.1615.006.html中图分类号:V231;TH113.1文献标志码:A文章编号:1006-7043(2023)02-0268-08Astudyontheinfluenceofmeshingmisalignmentonthevibrationresponseofhigh-speedgeartransmissionLILiangxiang1,WEIJing1,ZHANGAiqiang1,NIDe2,ZHONGTuanjie2(1.StateKeyLaboratoryofMechanicalTransmissions,ChongqingUniversity,Chongqing400044,China;2.ChinaAviationDevelop-mentHu'nanPowerMachineryResearchInstitute,Zhuzhou412000,China)Abstract:Meshingmisalignmentiseasilyproducedintheprocessofgeartransmissionbecauseofassemblyerroranddeformationunderload.Anabnormalmeshingstateaffectsthedynamiccharacteristicsofthesystem.Inparti-cular,fortheaviationhigh-speedgeartransmission,asmallmisalignmentmayalsoleadtoasharpdeclineinthesystem'sdynamicperformance.Inthisstudy,onthebasisofthetheoryandmethodofmultibodydynamicsmodel-ing,supercellpolycondensationisperformedontheshaftsandgears.Accordingtothecouplingrelationshipbe-tweenthemotionandloadoftheshaftingsystem,loadsandconstraintsareappliedateachcondensationnode,andfinally,thedynamicsmodelofanall-flexiblesingle-stageaviationspurgeartransmi...