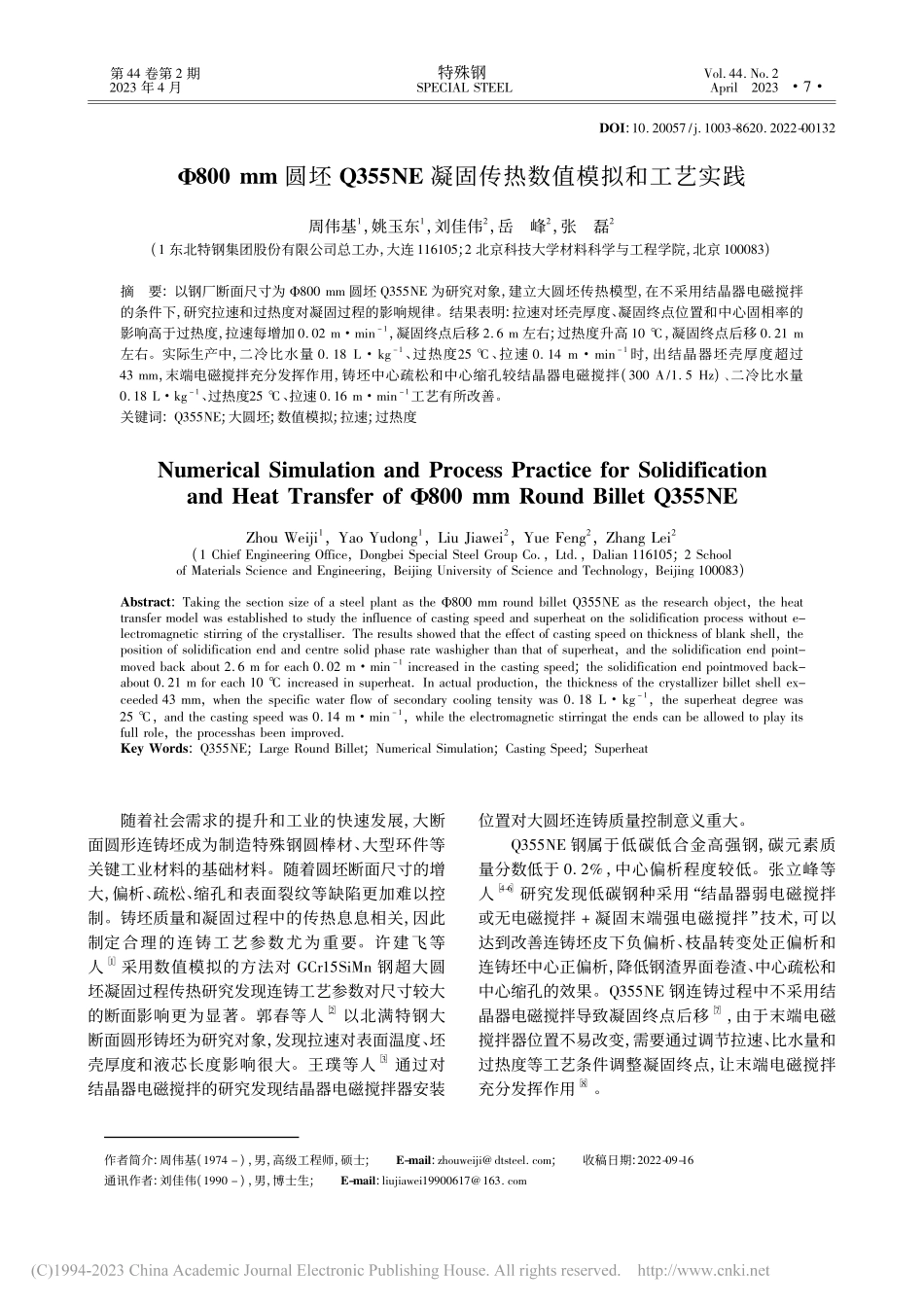

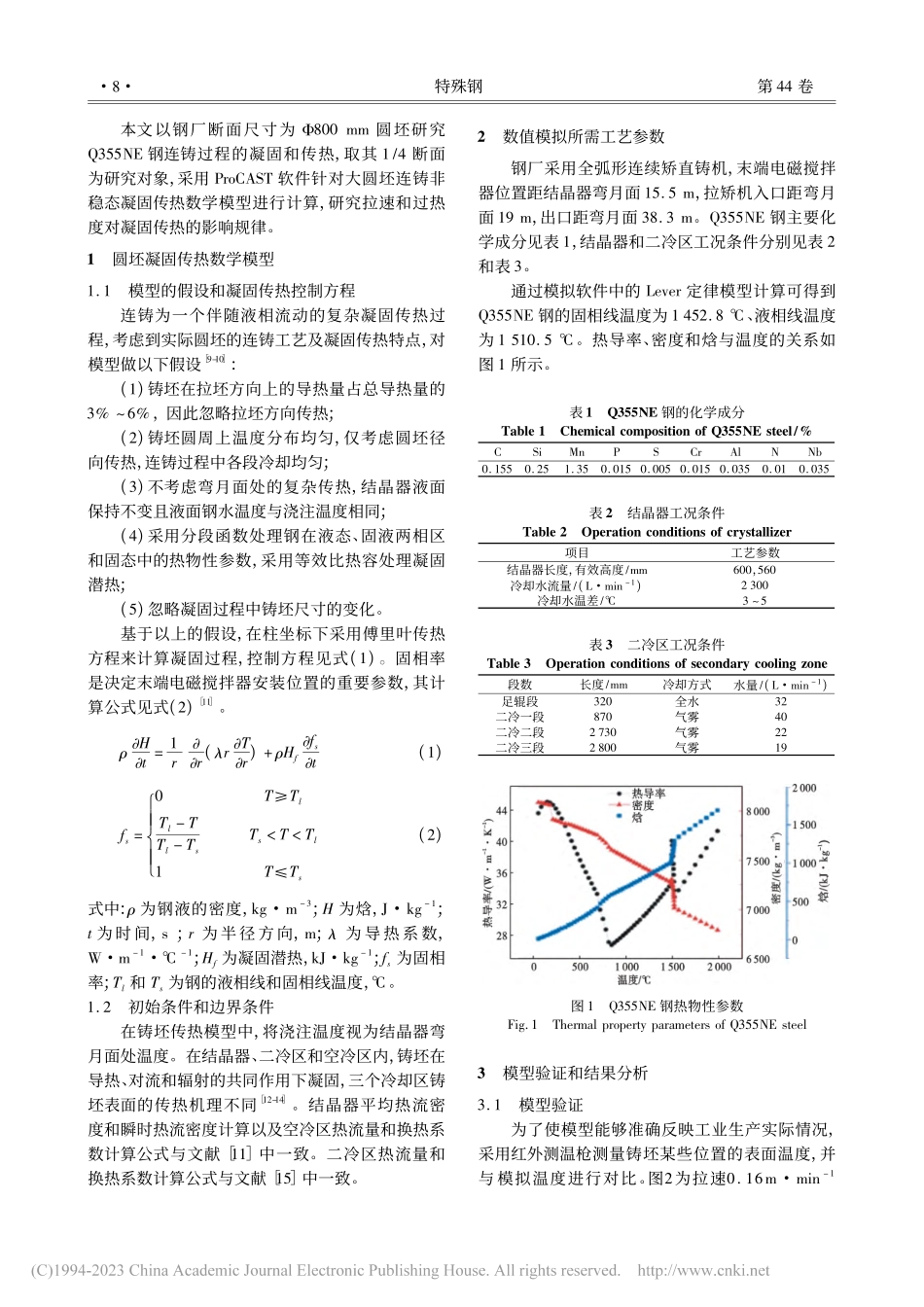

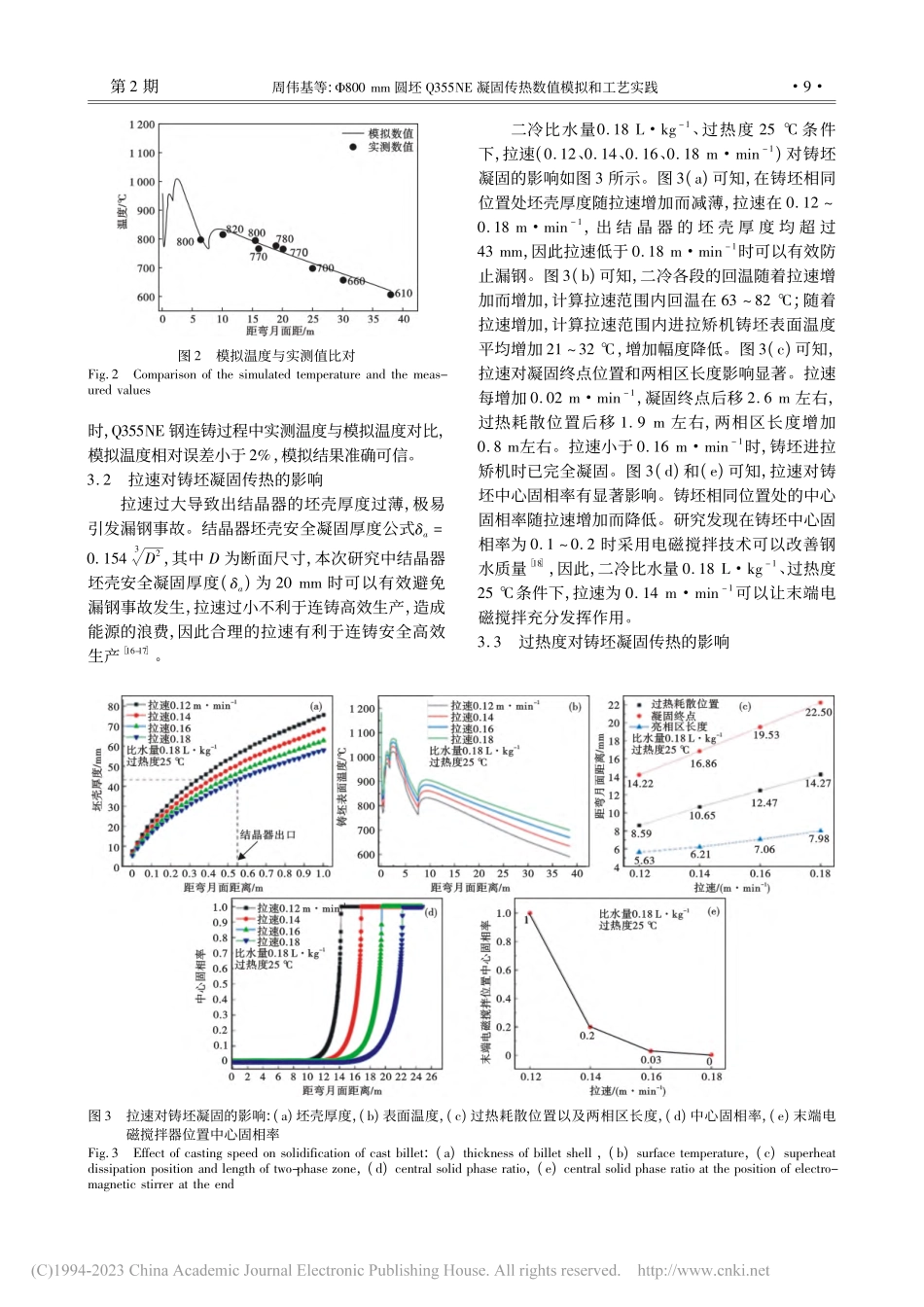

作者简介:周伟基(1974-),男,高级工程师,硕士;E-mail:zhouweiji@dtsteel.com;收稿日期:2022-09-16通讯作者:刘佳伟(1990-),男,博士生;E-mail:liujiawei19900617@163.comDOI:10.20057/j.1003-8620.2022-00132Φ800mm圆坯Q355NE凝固传热数值模拟和工艺实践周伟基1,姚玉东1,刘佳伟2,岳峰2,张磊2(1东北特钢集团股份有限公司总工办,大连116105;2北京科技大学材料科学与工程学院,北京100083)摘要:以钢厂断面尺寸为Φ800mm圆坯Q355NE为研究对象,建立大圆坯传热模型,在不采用结晶器电磁搅拌的条件下,研究拉速和过热度对凝固过程的影响规律。结果表明:拉速对坯壳厚度、凝固终点位置和中心固相率的影响高于过热度,拉速每增加0.02m·min-1,凝固终点后移2.6m左右;过热度升高10℃,凝固终点后移0.21m左右。实际生产中,二冷比水量0.18L·kg-1、过热度25℃、拉速0.14m·min-1时,出结晶器坯壳厚度超过43mm,末端电磁搅拌充分发挥作用,铸坯中心疏松和中心缩孔较结晶器电磁搅拌(300A/1.5Hz)、二冷比水量0.18L·kg-1、过热度25℃、拉速0.16m·min-1工艺有所改善。关键词:Q355NE;大圆坯;数值模拟;拉速;过热度NumericalSimulationandProcessPracticeforSolidificationandHeatTransferofΦ800mmRoundBilletQ355NEZhouWeiji1,YaoYudong1,LiuJiawei2,YueFeng2,ZhangLei2(1ChiefEngineeringOffice,DongbeiSpecialSteelGroupCo.,Ltd.,Dalian116105;2SchoolofMaterialsScienceandEngineering,BeijingUniversityofScienceandTechnology,Beijing100083)Abstract:TakingthesectionsizeofasteelplantastheΦ800mmroundbilletQ355NEastheresearchobject,theheattransfermodelwasestablishedtostudytheinfluenceofcastingspeedandsuperheatonthesolidificationprocesswithoute-lectromagneticstirringofthecrystalliser.Theresultsshowedthattheeffectofcastingspeedonthicknessofblankshell,thepositionofsolidificationendandcentresolidphaseratewashigherthanthatofsuperheat,andthesolidificationendpoint-movedbackabout2.6mforeach0.02m·min-1increasedinthecastingspeed;thesolidificationendpointmovedback-about0.21mforeach10℃increasedinsuperheat.Inactualproduction,thethicknessofthecrystallizerbilletshellex-ceeded43mm,whenthespecificwaterflowofsecondarycoolingtensitywas0.18L·kg-1,thesu...