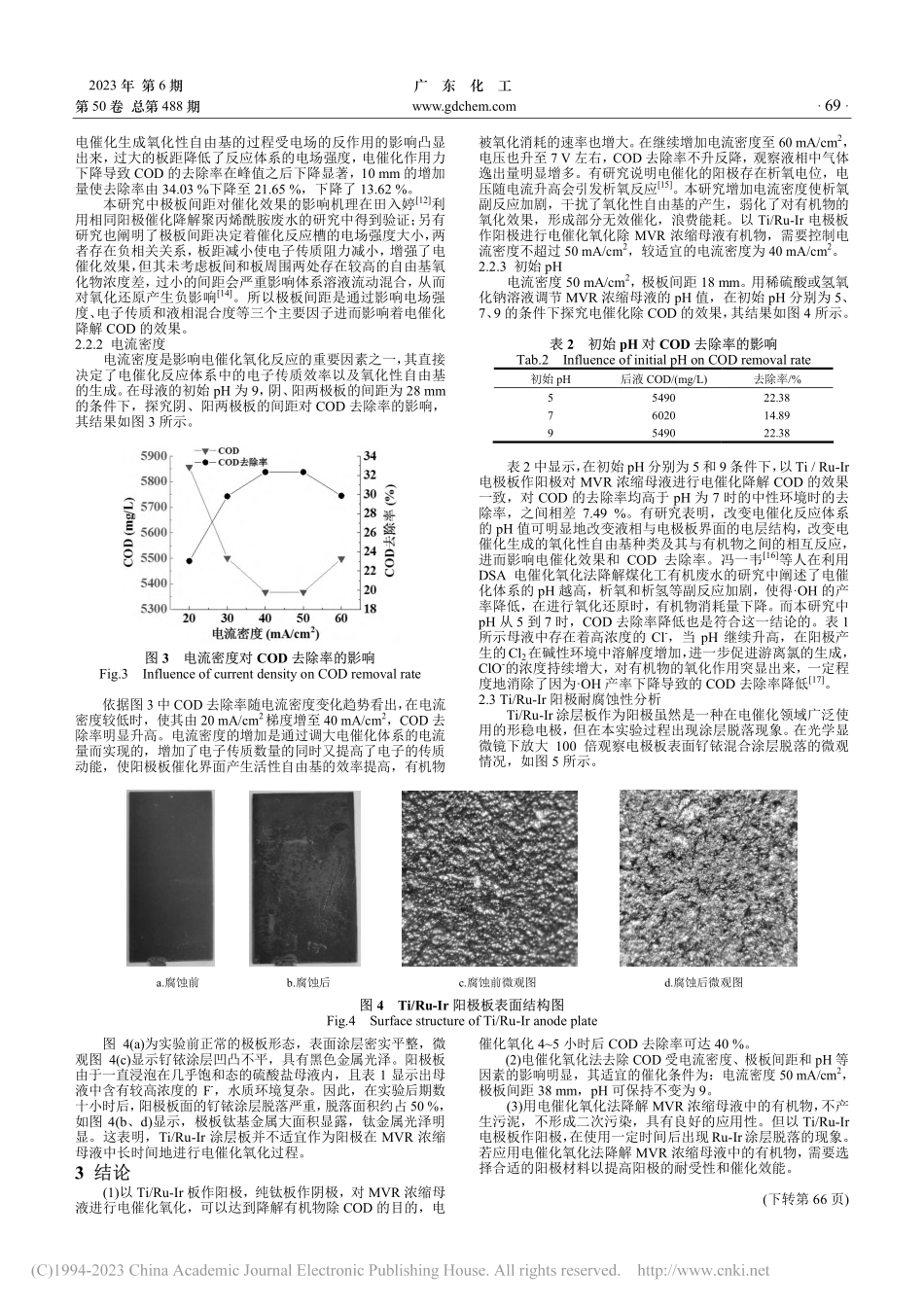

2023年第6期广东化工第50卷总第488期www.gdchem.com·67·Ti/Ru-Ir电极电催化氧化法降解MVR浓缩母液的研究卜兆骏,仇雅丽,刘勇奇,巩勤学,周俊杰(湖南邦普循环科技有限公司技术部,湖南长沙410000)[摘要]以钛基钌铱涂层电极板为阳极、纯钛电极板为阴极,对以废旧三元电池为原料进行湿法冶金回收锂过程产生的MVR浓缩母液开展电催化氧化降解有机物实验。以COD的去除率为指标评价有机物的降解率,探究了电极间距、电流密度和pH等因素对电催化结果的影响。确定适宜的条件为:电流密度50mA/cm2,极板间距38mm,pH为9。在此条件下,对300mL初始COD为7073mg/L的母液降解效果较好,电催化氧化2小时后的COD去除率可达35%左右。[关键词]钌铱电极;电催化氧化;湿法冶金;MVR浓缩母液;降解率[中图分类号]X703.1[文献标识码]A[文章编号]1007-1865(2023)06-0067-03StudyonDegradationofConcentratedMotherLiquorofMVRbyElectrocatalyticOxidationwithTi/Ru-IrElectrodeBuZhaojun,QiuYali,LiuYongqi,GongQinxue,ZhouJunjie(TechnologyDepartmentHunanBrunpRecyclingTechnologyCo.,Ltd.,Changsha410000,China)Abstract:Usingtitanium-Ruthenium-iridiumcoatedelectrodeplateasanodeandpuretitaniumelectrodeplateascathode,theelectrocatalyticoxidationoforganiccompoundsinconcentratedmotherliquorofMVRproducedfromwasteternarybatteriesintheprocessofhydrometallurgicalrecoveryoflithiumwascarriedout.TheremovalrateofCODwasusedastheindextoevaluatethedegradationrateoforganicmatter,andtheinfluenceofelectrodespacing,currentdensityandpHontheresultofelectrocatalysiswasexplored.Theoptimumconditionsareasfollows:currentdensity50mA/cm2,platespacing38mm,pH9.Undertheseconditions,thedegradationeffectof300mLmotherliquorwithinitialCODof7073mg/Lisgood,andtheCODremovalratecanreachabout35%after2hoursofelectrocatalyticoxidation.Keywords:ruthenium-iridiumelectrodes;electrocatalyticoxidation;hydrometallurgy;MVRconcentratedmotherliquor;degradationrate近年来,在国家政策的引领和大力支持下,我国电动汽车产业进入蓬勃发展时代,尤其是“十四五”开局之年以来,发展电动汽车已上升成为国家战略性政策,为实现2035年“碳达峰”战略目标布局[1]。预计2030年,我国电动汽车产能将高达8000万辆,满龄电动汽车的报废体量将逐...