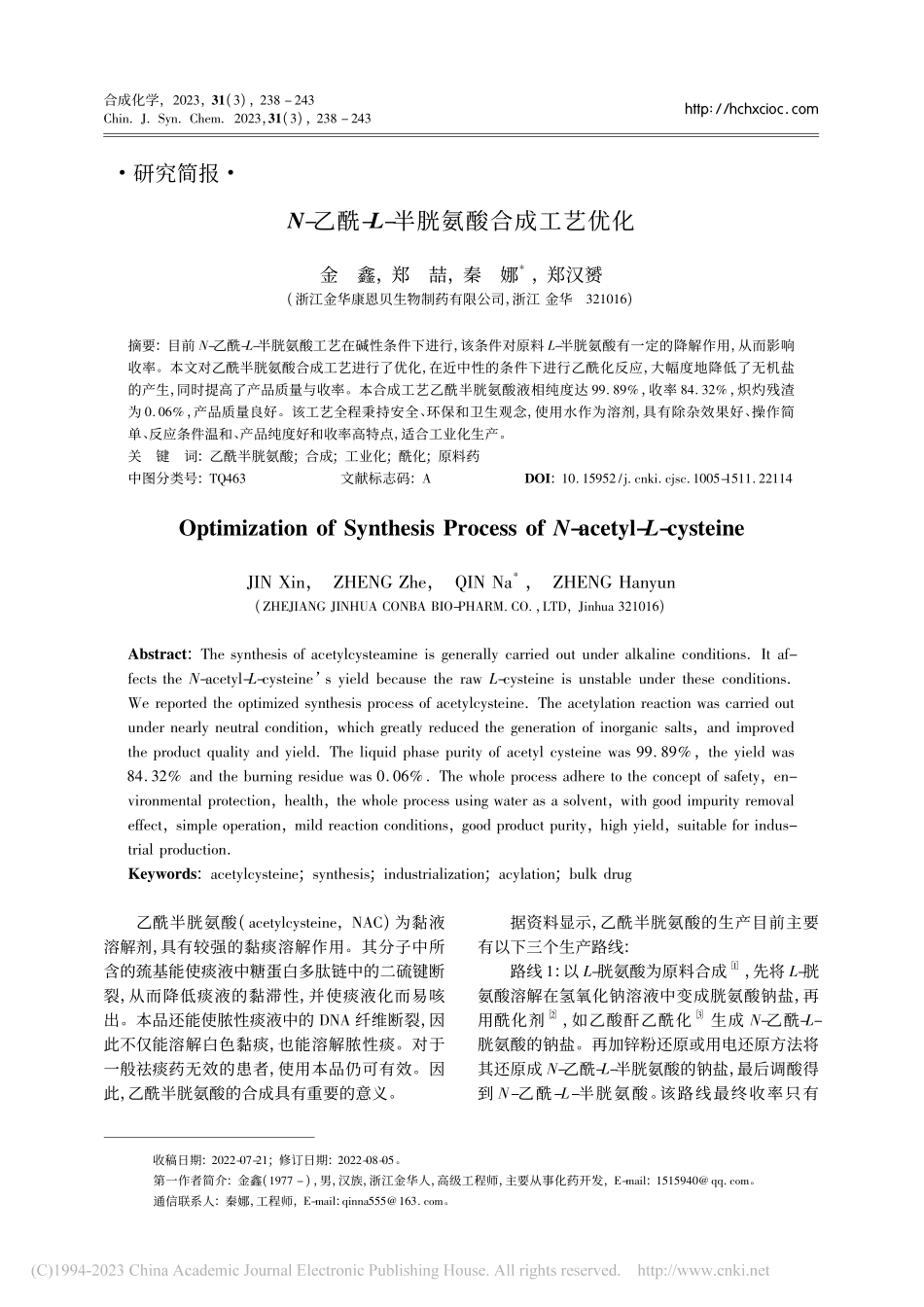

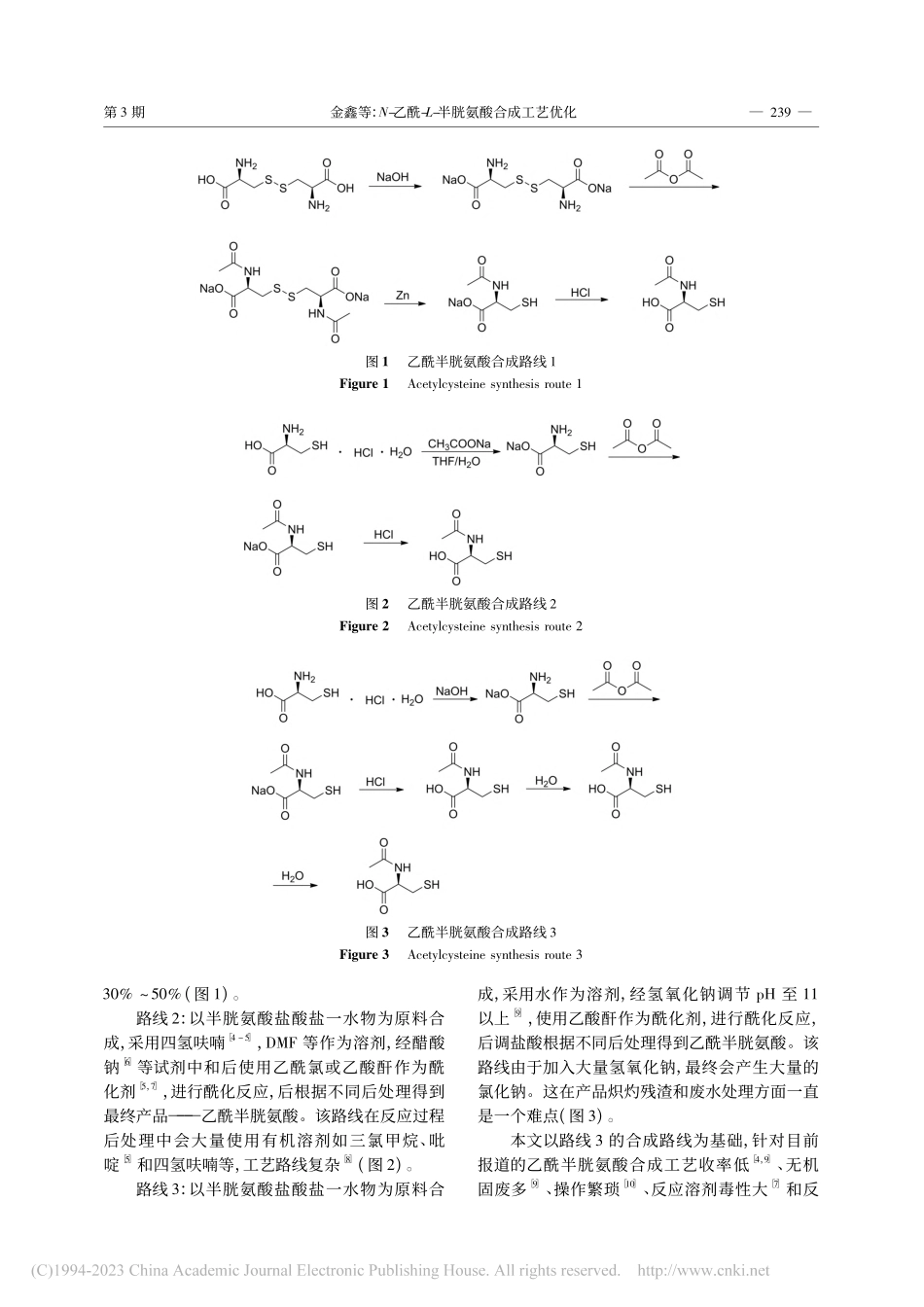

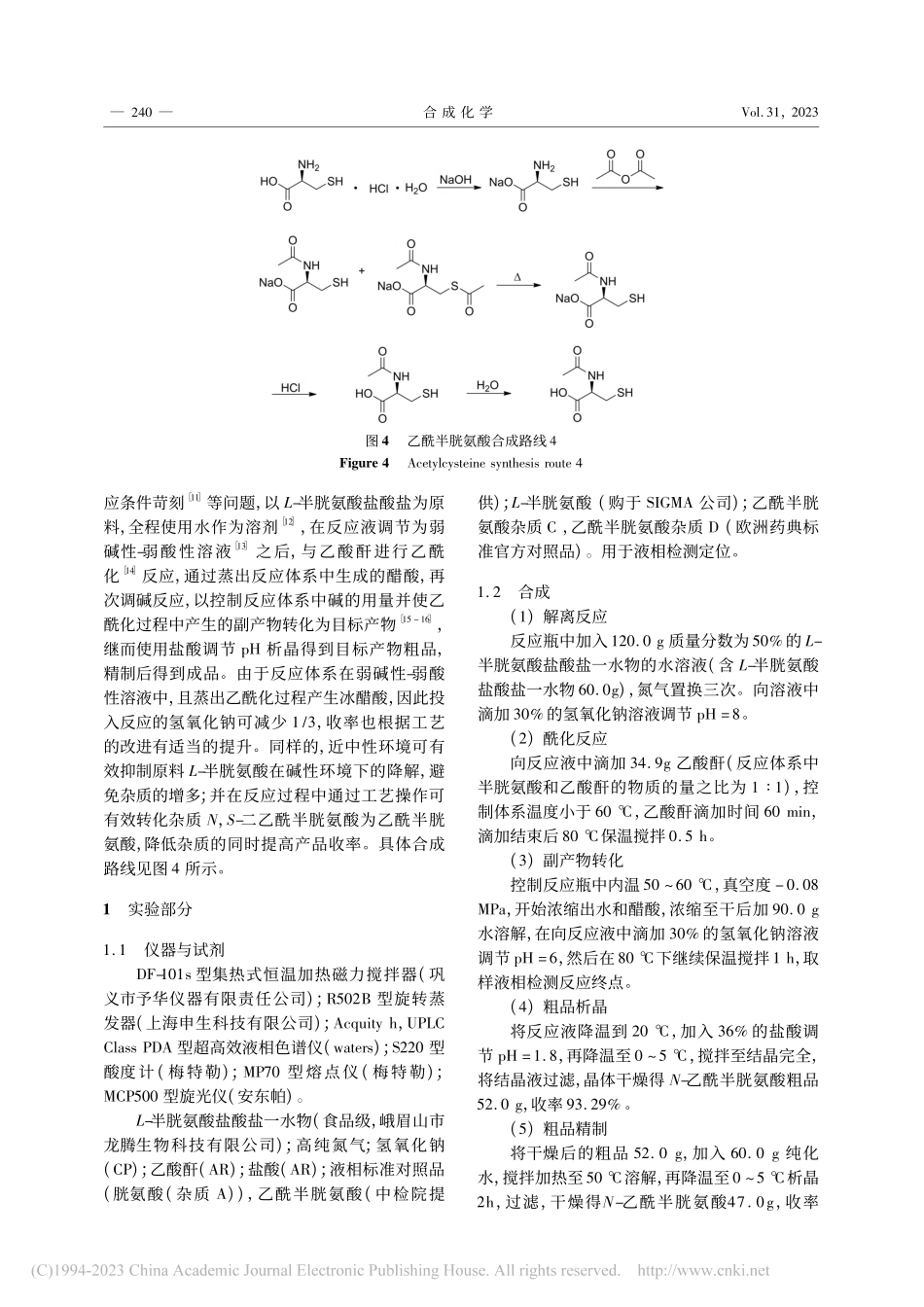

收稿日期:2022-07-21;修订日期:2022-08-05。第一作者简介:金鑫(1977-),男,汉族,浙江金华人,高级工程师,主要从事化药开发,E-mail:1515940@qq.com。通信联系人:秦娜,工程师,E-mail:qinna555@163.com。合成化学,2023,31(3),238-243Chin.J.Syn.Chem.2023,31(3),238-243http∶//hchxcioc.com·研究简报·N-乙酰-L-半胱氨酸合成工艺优化金鑫,郑喆,秦娜*,郑汉赟(浙江金华康恩贝生物制药有限公司,浙江金华321016)摘要:目前N-乙酰-L-半胱氨酸工艺在碱性条件下进行,该条件对原料L-半胱氨酸有一定的降解作用,从而影响收率。本文对乙酰半胱氨酸合成工艺进行了优化,在近中性的条件下进行乙酰化反应,大幅度地降低了无机盐的产生,同时提高了产品质量与收率。本合成工艺乙酰半胱氨酸液相纯度达99.89%,收率84.32%,炽灼残渣为0.06%,产品质量良好。该工艺全程秉持安全、环保和卫生观念,使用水作为溶剂,具有除杂效果好、操作简单、反应条件温和、产品纯度好和收率高特点,适合工业化生产。关键词:乙酰半胱氨酸;合成;工业化;酰化;原料药中图分类号:TQ463文献标志码:ADOI:10.15952/j.cnki.cjsc.1005-1511.22114OptimizationofSynthesisProcessofN-acetyl-L-cysteineJINXin,ZHENGZhe,QINNa*,ZHENGHanyun(ZHEJIANGJINHUACONBABIO-PHARM.CO.,LTD,Jinhua321016)Abstract:Thesynthesisofacetylcysteamineisgenerallycarriedoutunderalkalineconditions.Itaf-fectstheN-acetyl-L-cysteine’syieldbecausetherawL-cysteineisunstableundertheseconditions.Wereportedtheoptimizedsynthesisprocessofacetylcysteine.Theacetylationreactionwascarriedoutundernearlyneutralcondition,whichgreatlyreducedthegenerationofinorganicsalts,andimprovedtheproductqualityandyield.Theliquidphasepurityofacetylcysteinewas99.89%,theyieldwas84.32%andtheburningresiduewas0.06%.Thewholeprocessadheretotheconceptofsafety,en-vironmentalprotection,health,thewholeprocessusingwaterasasolvent,withgoodimpurityremovaleffect,simpleoperation,mildreactionconditions,goodproductpurity,highyield,suitableforindus-trialproduction.Keywords:acetylcysteine;synthesis;industrialization;acylation;bulkdrug乙酰半胱氨酸(acetylcysteine,NAC)为黏液溶解剂,具有较强的黏痰溶解作用。其分子中所含的...