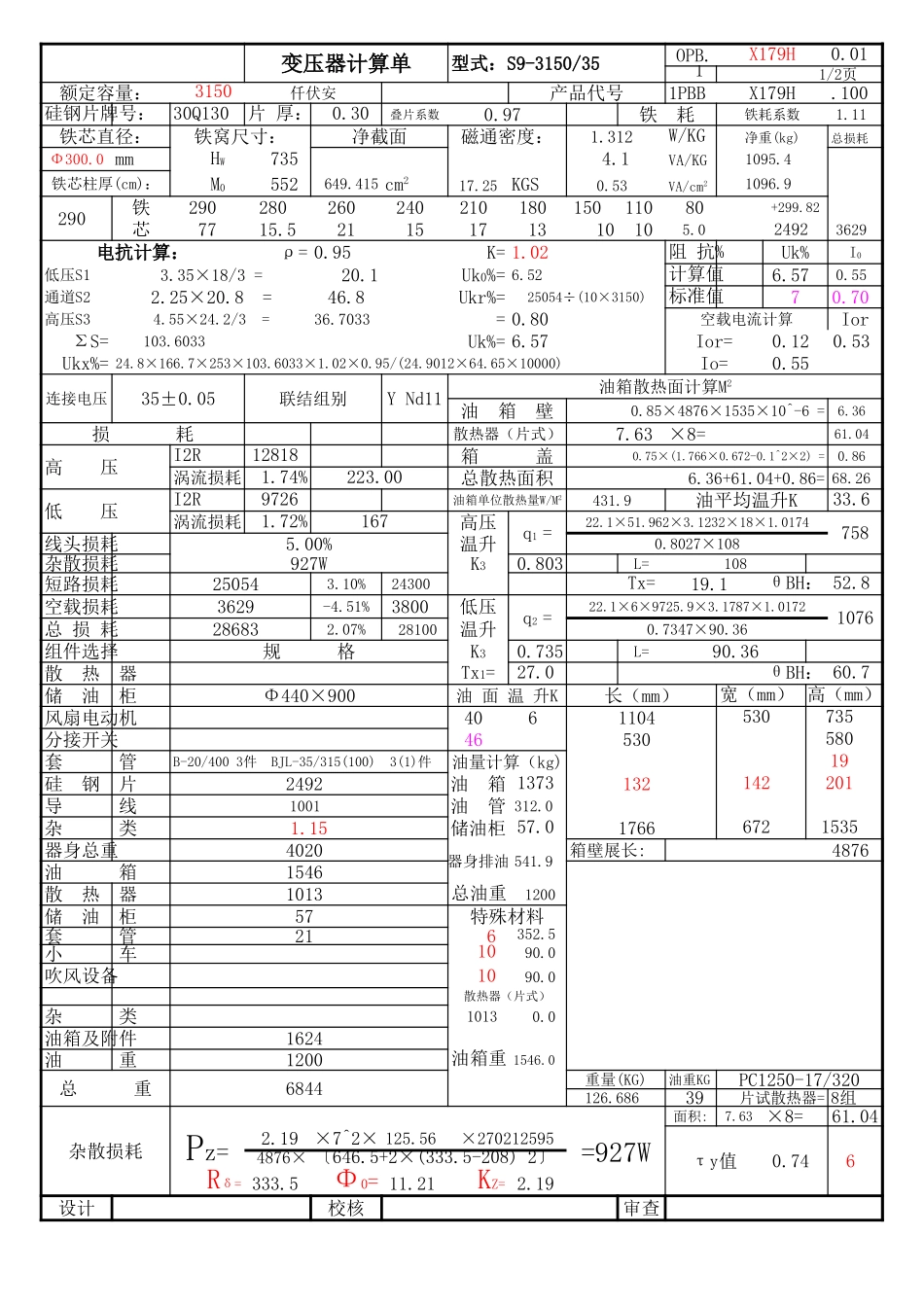

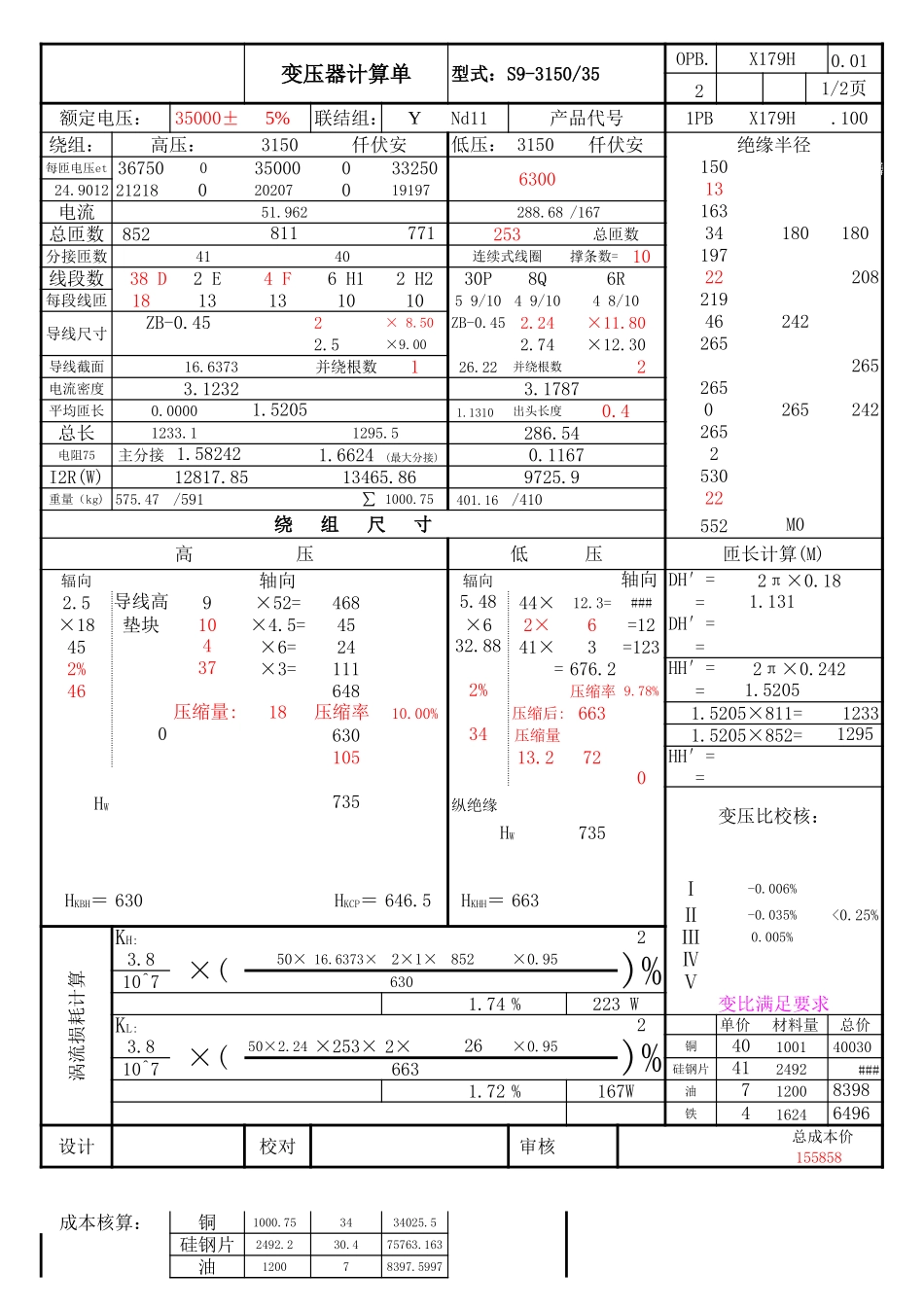

变压器计算单OPB.X179H0.011额定容量:3150仟伏安产品代号1PBBX179H.100硅钢片牌号:30Q130片厚:0.30叠片系数0.97铁耗铁耗系数1.11铁芯直径:铁窝尺寸:净截面磁通密度:1.312W/KG总损耗Φ300.0mm7354.1VA/KG1095.4552649.41517.25KGS0.531096.9290铁29028026024021018015011080+299.82芯7715.52115171310105.024923629电抗计算:ρ=0.95K=1.02Uk%3.35×18/3=20.16.52计算值6.570.552.25×20.8=46.8Ukr%=25054÷(10×3150)标准值70.704.55×24.2/3=36.7033=0.80空载电流计算IorΣS=103.60336.57Ior=0.120.53Ukx%=24.8×166.7×253×103.6033×1.02×0.95/(24.9012×64.65×10000)Io=0.55连接电压35±0.05联结组别YNd11油箱壁0.85×4876×1535×10^-6=6.36散热器(片式)7.63×8=61.04高压I2R12818箱盖0.75×(1.766×0.672-0.1^2×2)=0.86涡流损耗1.74%223.00总散热面积6.36+61.04+0.86=68.26低压I2R9726431.933.6涡流损耗1.72%167高压22.1×51.962×3.1232×18×1.0174758线头损耗5.00%温升0.8027×108杂散损耗927W0.803L=108短路损耗250543.10%24300Tx=19.152.8空载损耗3629-4.51%3800低压22.1×6×9725.9×3.1787×1.01721076总损耗286832.07%28100温升0.7347×90.36组件选择规格0.735L=90.36散热器27.060.7储油柜Φ440×900风扇电动机4061104530735分接开关46530580套管19硅钢片2492油箱1373132142201导线1001油管312.0杂类1.15储油柜57.017666721535器身总重4020器身排油541.94876油箱1546散热器1013总油重1200储油柜57特殊材料套管216352.5小车1090.0吹风设备1090.0散热器(片式)杂类10130.0油箱及附件1624油重1200油箱重1546.0总重6844PC1250-17/320126.68639杂散损耗7.63×8=61.042.19×7^2×125.56×270212595=927W0.7464876×333.511.212.19设计校核审查型式:S9-3150/351/2页净重(kg)HW铁芯柱厚(cm):M0cm2VA/cm2阻抗%I0低压S1Uk0%=通道S2高压S3Uk%=油箱散热面计算M2损耗油箱单位散热量W/M2油平均温升Kq1=K3θBH:q2=K3Tx1=θBH:油面温升K长(mm)宽(mm)高(mm)B-20/4003件BJL-35/315(100)3(1)件油量计算(kg)箱壁展长:重量(KG)油重KG片试散热器=8组面积:Pz=τy值〔646.5+2×(333.5-208)^2〕Rδ=Φ0=KZ=变压器计算单OPB.X179H0.012额定电压:35000±5%联结组:YNd11产品代号1PBX179H.100绕组:高压:3150仟伏安低压:3150仟伏安绝缘半径367500350000332506300150长阻抗计算24.90122121802020701919713电流51.962288.68/167163总匝...