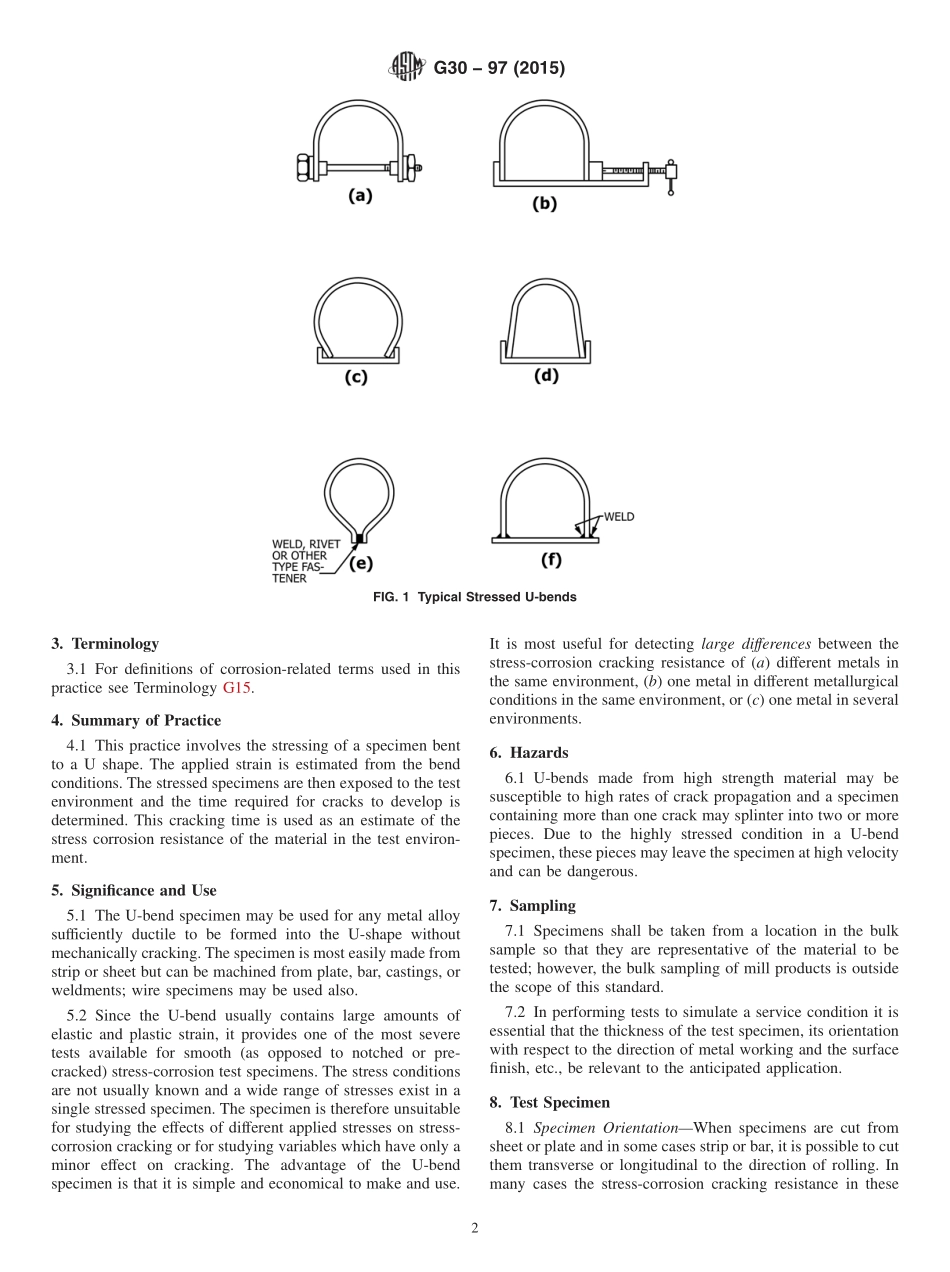

Designation:G30−97(Reapproved2015)StandardPracticeforMakingandUsingU-BendStress-CorrosionTestSpecimens1ThisstandardisissuedunderthefixeddesignationG30;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1ThispracticecoversproceduresformakingandusingU-bendspecimensfortheevaluationofstress-corrosioncrack-inginmetals.TheU-bendspecimenisgenerallyarectangularstripwhichisbent180°aroundapredeterminedradiusandmaintainedinthisconstantstrainconditionduringthestress-corrosiontest.Bendsslightlylessthanorgreaterthan180°aresometimesused.TypicalU-bendconfigurationsshowingsev-eraldifferentmethodsofmaintainingtheappliedstressareshowninFig.1.1.2U-bendspecimensusuallycontainbothelasticandplasticstrain.Insomecases(forexample,verythinsheetorsmalldiameterwire)itispossibletoformaU-bendandproduceonlyelasticstrain.However,bent-beam(PracticeG39ordirecttension(PracticeG49))specimensarenormallyusedtostudystress-corrosioncrackingofstriporsheetunderelasticstrainonly.1.3Thispracticeisconcernedonlywiththetestspecimenandnottheenvironmentalaspectsofstress-corrosiontestingwhicharediscussedelsewhere(1)2andinPracticesG35,G36,G37,G41,G44,G103andTestMethodG123.1.4ThevaluesstatedinSIunitsaretoberegardedasstandard.Theinch-poundunitsinparenthesesareprovidedforinformation.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:3E3GuideforPreparationofMetallographicSpecimensG1PracticeforPreparing,Cleaning,andEvaluatingCorro-sionTestSpecimensG15TerminologyRelatingtoCorrosionandCorrosionTest-ing(Withdrawn2010)4G35PracticeforDeterminingtheSusceptibilityofStainlessSteelsandRela...