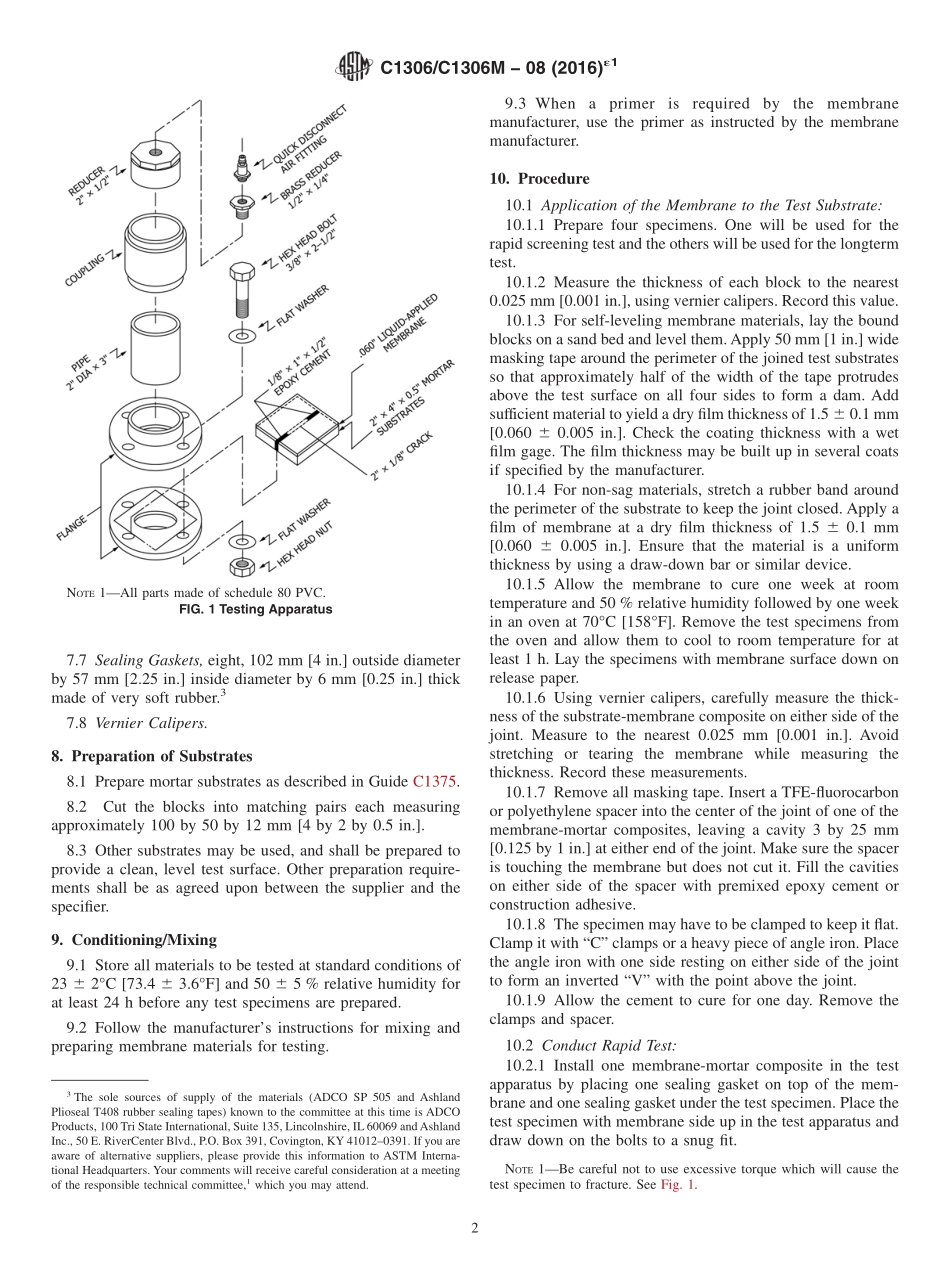

Designation:C1306/C1306M−08(Reapproved2016)´1StandardTestMethodforHydrostaticPressureResistanceofaLiquid-AppliedWaterproofingMembrane1ThisstandardisissuedunderthefixeddesignationC1306/C1306M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ε1NOTE—UnitsinformationwaseditoriallycorrectedinNovember2016.1.Scope1.1Thistestmethoddescribesalaboratoryprocedurefordeterminingtheresistanceofawaterproofingmembranetohydrostaticpressure.1.2Thecommitteewithjurisdictionoverthisstandardisnotawareofanycomparablestandardspublishedbyotherorga-nizations.1.3TherearenoISOstandardssimilarorequivalenttothisASTMstandard.1.4ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2C717TerminologyofBuildingSealsandSealantsC1375GuideforSubstratesUsedinTestingBuildingSealsandSealants3.Terminology3.1Definitions—RefertoTerminologyC717fordefinitionsoftechnicaltermsusedinthistestmethod.4.SummaryofTestMethod4.1Thistestmethodisconductedintwostages.Inthefirststage,thetestmembraneissubjectedtohydrostaticpressurethatisincreasedsteadilyoveran8hperioduntilthespecimenfailsorthemaximumpressureisachieved.Inthesecondpartofthetest,threemorespecimensaresubjectedtohydrostaticpressurethatisincreasedslowlyfrom50%ofthefailurevaluetofailurein2.5psiincrementseverytwotothreedays.5.SignificanceandUse5.1Thistestmethodisusedasascree...