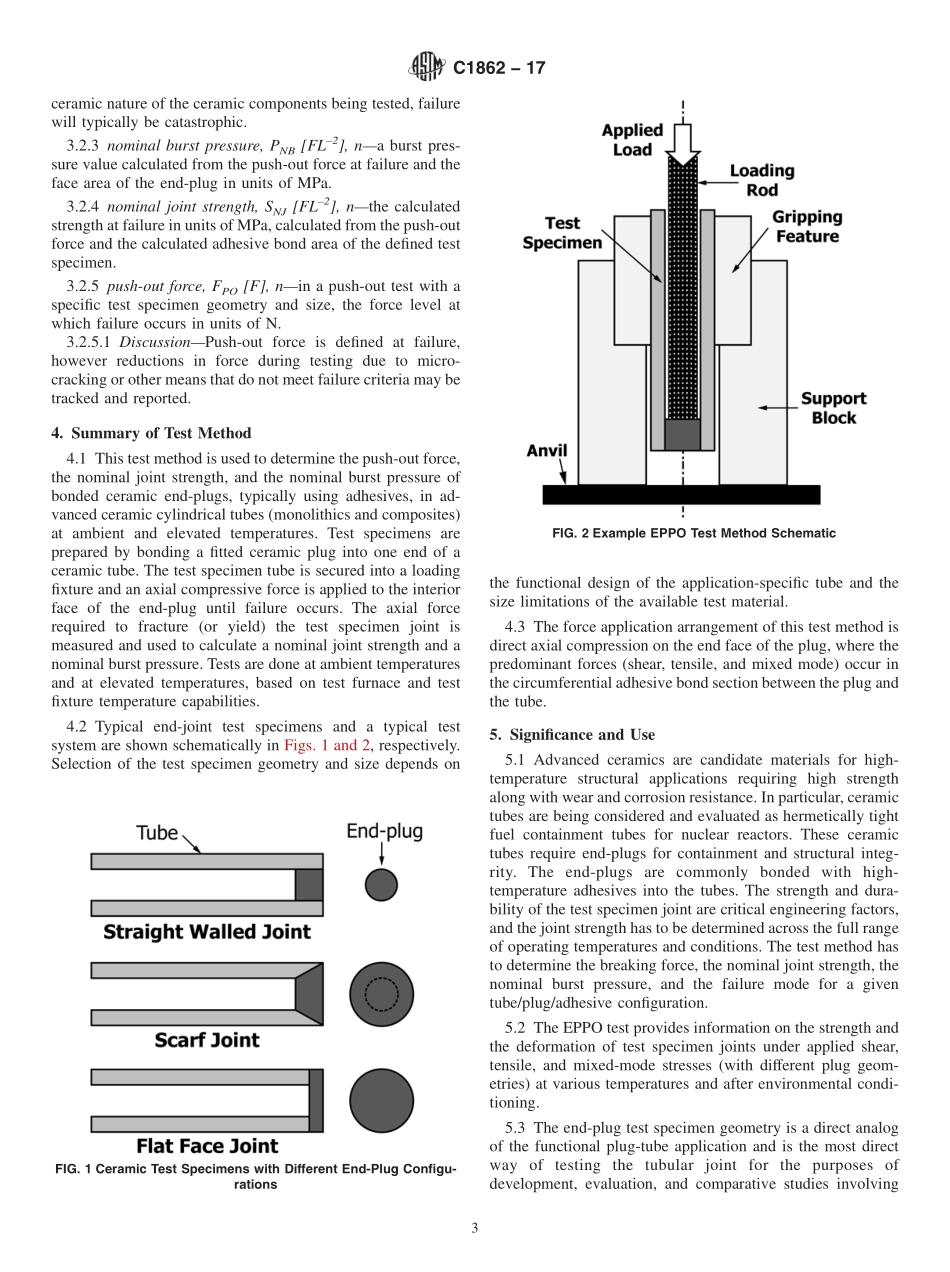

Designation:C1862−17StandardTestMethodfortheNominalJointStrengthofEnd-PlugJointsinAdvancedCeramicTubesatAmbientandElevatedTemperatures1ThisstandardisissuedunderthefixeddesignationC1862;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofthepush-outforce,nominaljointstrength,andnominalburstpressureofbondedceramicend-plugsinadvancedceramiccylindricaltubes(monolithicandcomposite)atambientandelevatedtemperatures(see4.2).Thetestmethodisbroadinscopeandend-plugsmayhaveavarietyofdifferentconfigurations,jointtypes,andgeometries.Itisexpectedthatthemostcommontypeofjointstestedareadhesivelybondedend-plugsthatuseorganicadhesives,metals,glasssealants,andceramicadhe-sives(sinteredpowders,sol-gel,polymer-derivedceramics)asthebondingmaterialbetweentheend-plugandthetube.Thistestmethoddescribesthetestcapabilitiesandlimitations,thetestapparatus,testspecimengeometriesandpreparationmethods,testprocedures(modes,rates,mounting,alignment,testingmethods,datacollection,andfractureanalysis),calcu-lationmethods,andreportingprocedures.1.2Inthisend-plugpush-out(EPPO)testmethod,testspecimensarepreparedbybondingafittedceramicplugintooneendofaceramictube.Thetestspecimentubeissecuredintoagrippingfixtureandtestapparatus,andanaxialcompressiveforceisappliedtotheinteriorfaceoftheplugtopushitoutofthetube.(See4.2.)Theaxialforcerequiredtofracture(orpermanentlydeform)thejoinedtestspecimenismeasuredandusedtocalculateanominaljointstrengthandanominalburstpressure.Testsareperformedatambientorelevatedtemperatures,orboth,basedonthetemperaturecapabilitiesofthetestfurnaceandthetestapparatus.1.3Thistestmethodisapplicabletoend-plugtestspeci-menswithawiderangeofconfigurationsandsizes.Thetestmethoddoesnotdefineastandardizedtestspecimengeometry,becausethepurposeofthete...