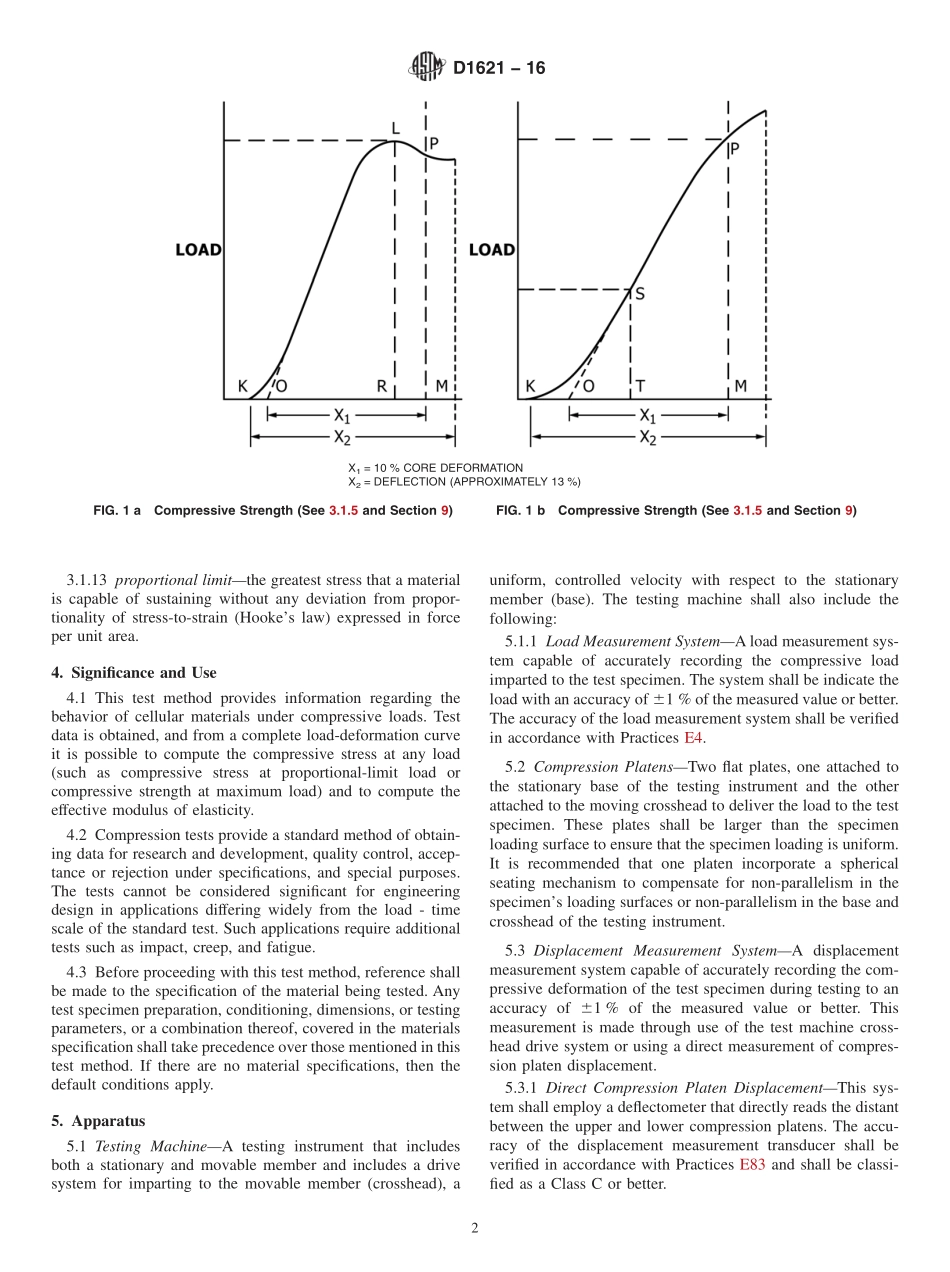

Designation:D1621−16StandardTestMethodforCompressivePropertiesofRigidCellularPlastics1ThisstandardisissuedunderthefixeddesignationD1621;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thistestmethoddescribesaprocedurefordeterminingthecompressivepropertiesofrigidcellularmaterials,particu-larlyexpandedplastics.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesinparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE1—ThistestmethodandISO844aretechnicallyequivalent.2.ReferencedDocuments2.1ASTMStandards:2D618PracticeforConditioningPlasticsforTestingE4PracticesforForceVerificationofTestingMachinesE83PracticeforVerificationandClassificationofExten-someterSystemsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod2.2ISOStandard:ISO844CellularPlastics—CompressionTestofRigidMa-terials33.Terminology3.1Definitions:3.1.1compliance—thedisplacementdifferencebetweentestmachinedrivesystemdisplacementvaluesandactualspecimendisplacement.3.1.2compliancecorrection—ananalyticalmethodofmodifyingtestinstrumentdisplacementvaluestoeliminatetheamountofthatmeasurementattributedtotestinstrumentcompliance.3.1.3compressivedeformation—thedecreaseinlengthpro-ducedinthegagelengthofthetestspecimenbyacompressiveloadexpressedinunitsoflength.3.1.4compressivestrain—thedimensionlessratioofcom-pressivedeformationtothegagelengthofthetestspecimenorthechangeinlengthperunitoforiginallengthalongthelongitudinalaxis.3.1.5compressivestrength—thestress...