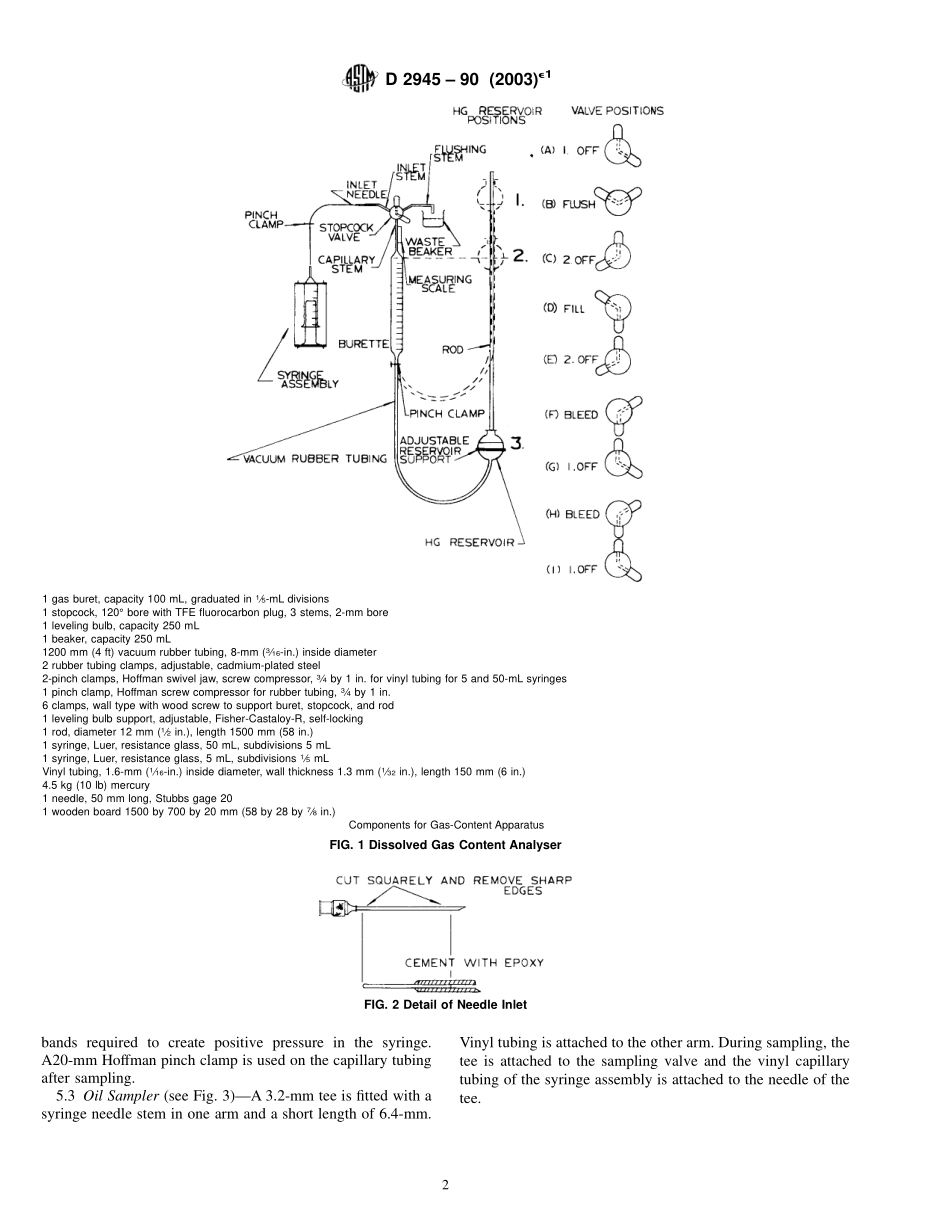

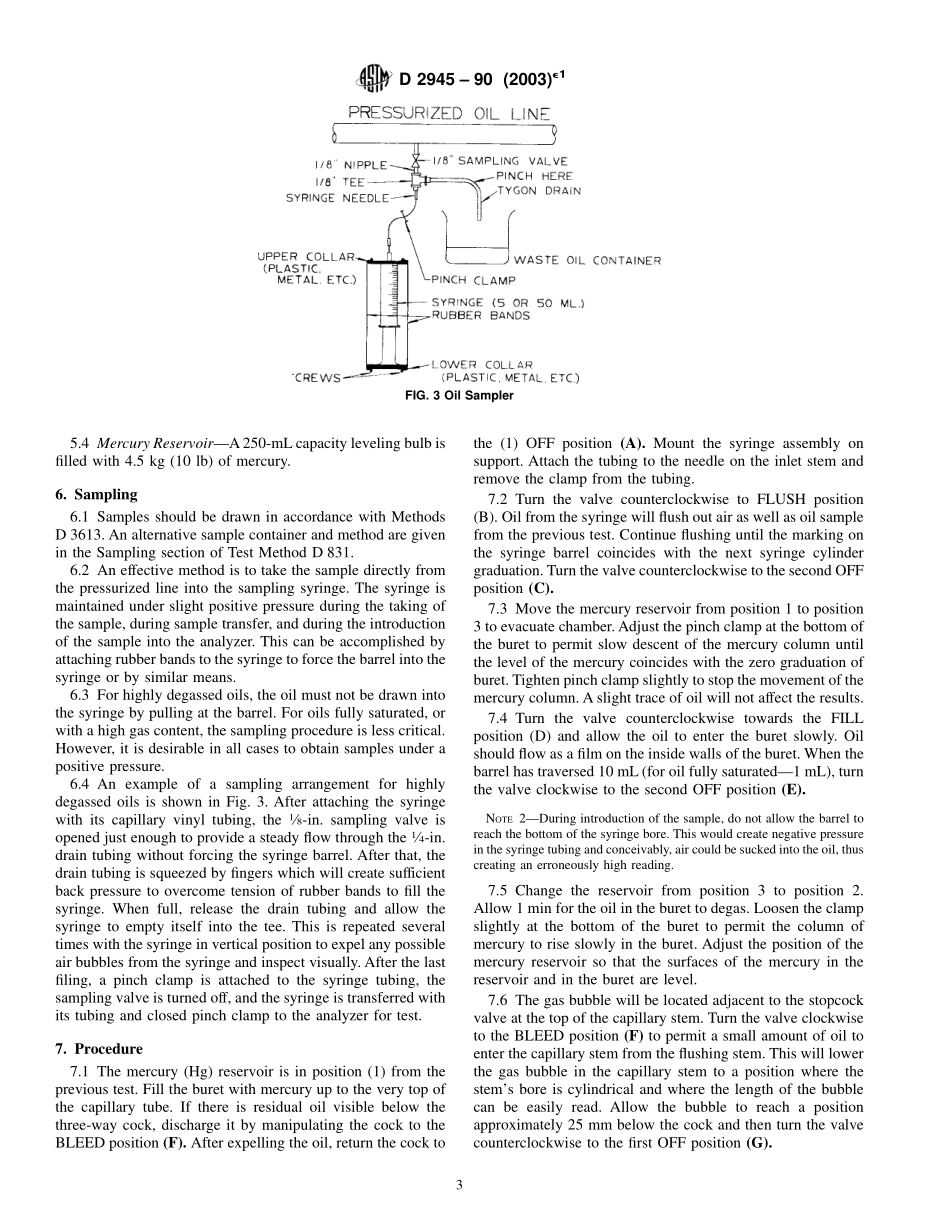

Designation:D2945–90(Reapproved2003)e1StandardTestMethodforGasContentofInsulatingOils1ThisstandardisissuedunderthefixeddesignationD2945;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.e1NOTE—ThemetricvaluefortheinsidediameterofvinyltubinginFig.1wascorrectededitoriallyinDecember2003.1.Scope1.1Thistestmethodcoversthedeterminationofthegascontentofelectricalinsulatingoilsoflowandmediumviscositiesinthegeneralrangeof100SUSandbelowat100°F(37.8°C),andissuitableforfieldorlaboratoryuse.NOTE1—Fortestinginsulatingoilswithviscositiesabove100SUS,seeTestMethodD831.Forindividualgasconcentrations,seeMethodD3612.1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D831TestMethodforGasContentofCableandCapacitorOilsD3612TestMethodforAnalysisofGasesDissolvedinElectricalInsulatingOilbyGasChromatographyD3613PracticeforSamplingInsulatingLiquidsforGasAnalysisandDeterminationofWaterContent3.SummaryofTestMethod3.1Thistestmethodconsistsessentiallyofallowingoiltoflowintoanevacuatedchamberasathinfilmsothattheoilisthoroughlyexposedtothevacuum,allowingfreevolatilizationofthegaseouscomponent.Thesystemisbroughtbacktoatmosphericpressure,andtheevolvedgasesmeasured.Fromthevolumeofoildegassedinthechamberandthevolumeofreleasedgas,thepercentgascontentmaybeestimated.Theapparatususedproducesthenecessaryvacuumwithoutresort-ingtouseofavacuumpump.Thistestmethodpartiallydegasestheoil.Thedegreeofdegasificationvarieswiththesolubilityofeachgasintheoil.4.SignificanceandUse4.1Infillingelectricalapparatus,itisdesirabletouselowgascontenttransformeroilinordertopreventfoamingandtoavoi...