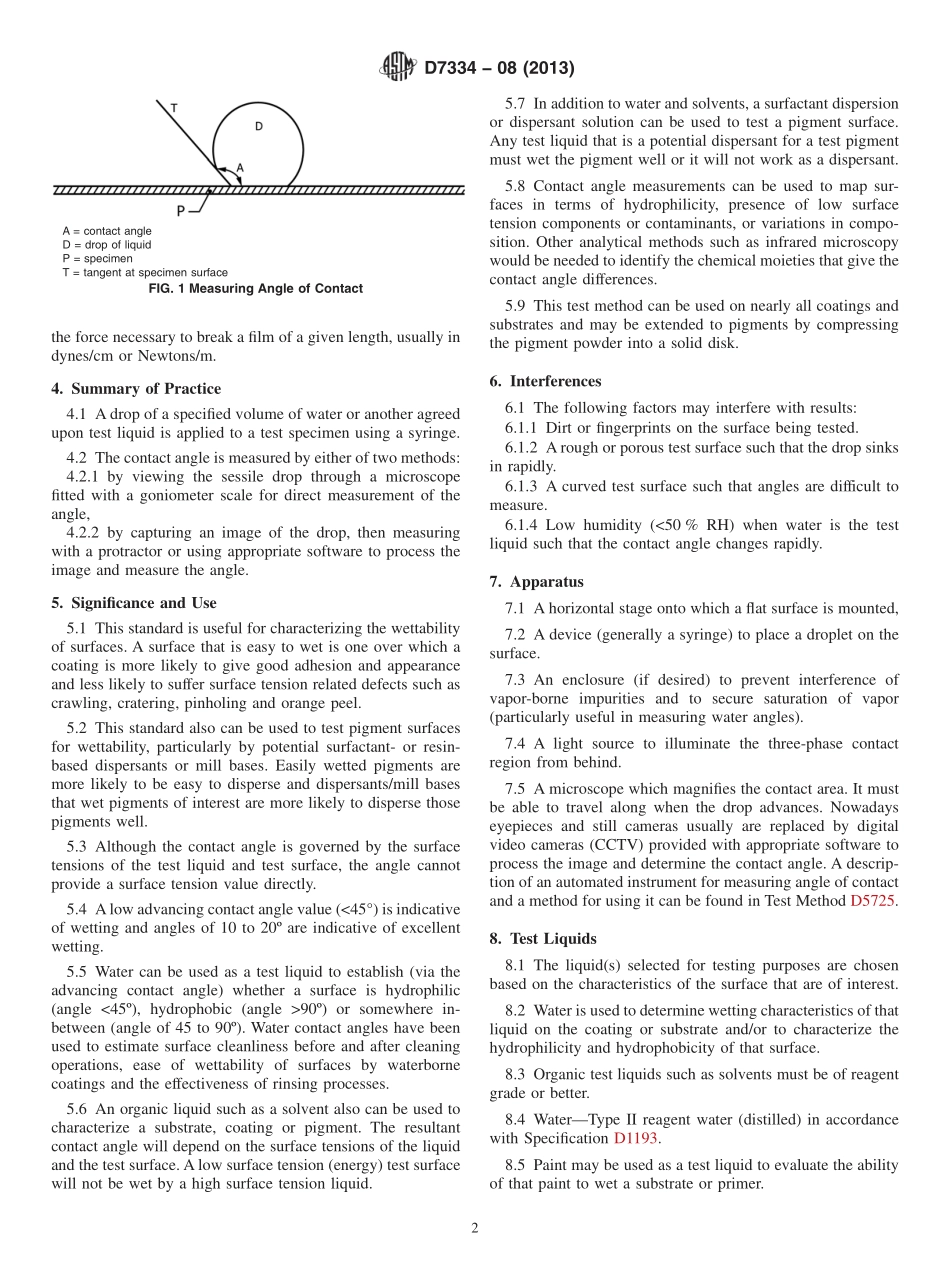

Designation:D7334−08(Reapproved2013)StandardPracticeforSurfaceWettabilityofCoatings,SubstratesandPigmentsbyAdvancingContactAngleMeasurement1ThisstandardisissuedunderthefixeddesignationD7334;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoversthemeasurementoftheangleofcontactwhenadropofliquidisappliedtoacoatedsurface,substrate,orpreformeddiskofpigment.1.2Therearetwotypesofcontactangles,advancingandreceding.Thisstandarddealsonlywithadvancingcontactangles.1.3Thispracticeisintendedtosupplementthemanufactur-er’sinstructionsforthedevicebeingusedtomakethemeasurements,butisnotintendedtoreplacethem.1.4Acommontestliquidiswater,butmanyotherliquidssuchassolvents,surfactantanddispersantsolutionsandevenliquidpaintscanbeused.1.5Thispracticeisbasedongoniometry,whichinvolvestheobservationofasessiledropoftestliquidonasolidsubstrate.1.6Althoughcontactanglesaregovernedbysurfacetension,thisstandardcannotbeusedtomeasuresurfacetensiondirectly.1.7ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.8Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D1193SpecificationforReagentWaterD5725TestMethodforSurfaceWettabilityandAbsorbencyofSheetedMaterialsUsinganAutomatedContactAngleTester(Withdrawn2010)33.Terminology3.1Definitions:3.1.1advancingcontactangle,n—thecontactanglethatismeasuredimmediatelyafterthesessiledropisplacedonthesurface.3.1.1.1Discussion—Thedrophasthemaximumvolumeallowablefortheliquid-solidinterfacialarea:anyadditionwillmakethedropexpandandincreasetheliquid-solidinterfac...