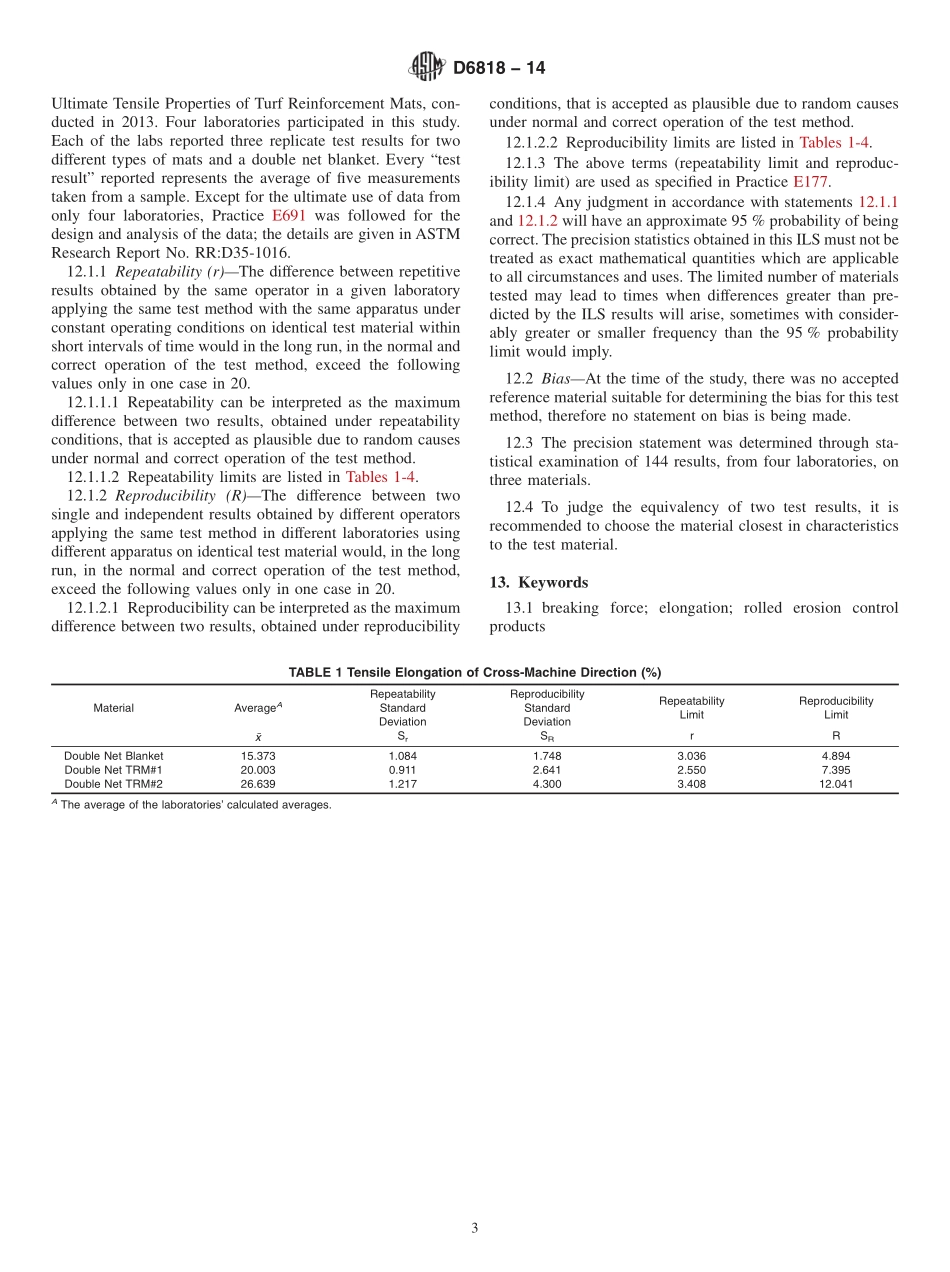

Designation:D6818−14StandardTestMethodforUltimateTensilePropertiesofRolledErosionControlProducts1ThisstandardisissuedunderthefixeddesignationD6818;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversstriptestproceduresfordeter-miningthetensilepropertiesofRolledErosionControlProd-ucts(RECP).1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareprovidedforinformationpurposesonly.1.3ThisstandarddoesnotapplytoRECP’smadeofcompositematerialswherethecomponentprovidingtherein-forcementcannotbetestedfortensilestrengthwiththeprocedurehereindescribed.Inthiscase,theestablishedASTMtestingmethod,whichismostappropriateforthatmaterial,shallbeusedinstead.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D76/D76MSpecificationforTensileTestingMachinesforTextilesE177PracticeforUseoftheTermsPrecisionandBiasinASTMTestMethodsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.Terminology3.1Definitions:3.1.1breakingload,n—themaximumforceappliedtoaspecimeninatensiletestcarriedtorupture.3.1.1.1Discussion—Materialsthatarebrittleusuallyrup-tureatthemaximumforce.Materialsthatareductileusuallyexperienceamaximumforcebeforerupturing.3.1.2constantrateofextension(CRE)tensiletestingmachine—atestingmachineinwhichtherateofincreaseofspecimenlengthisuniformwithtime.3.1.3elongation,n—theratiooftheextensionofamaterialtothelengthofthematerialpriortostretching.(Compareextension.)3.1.4extension,n—thechangeinlengthofamaterialduetostretching.(Compareelongation.)3.1.5rupture,v—the...