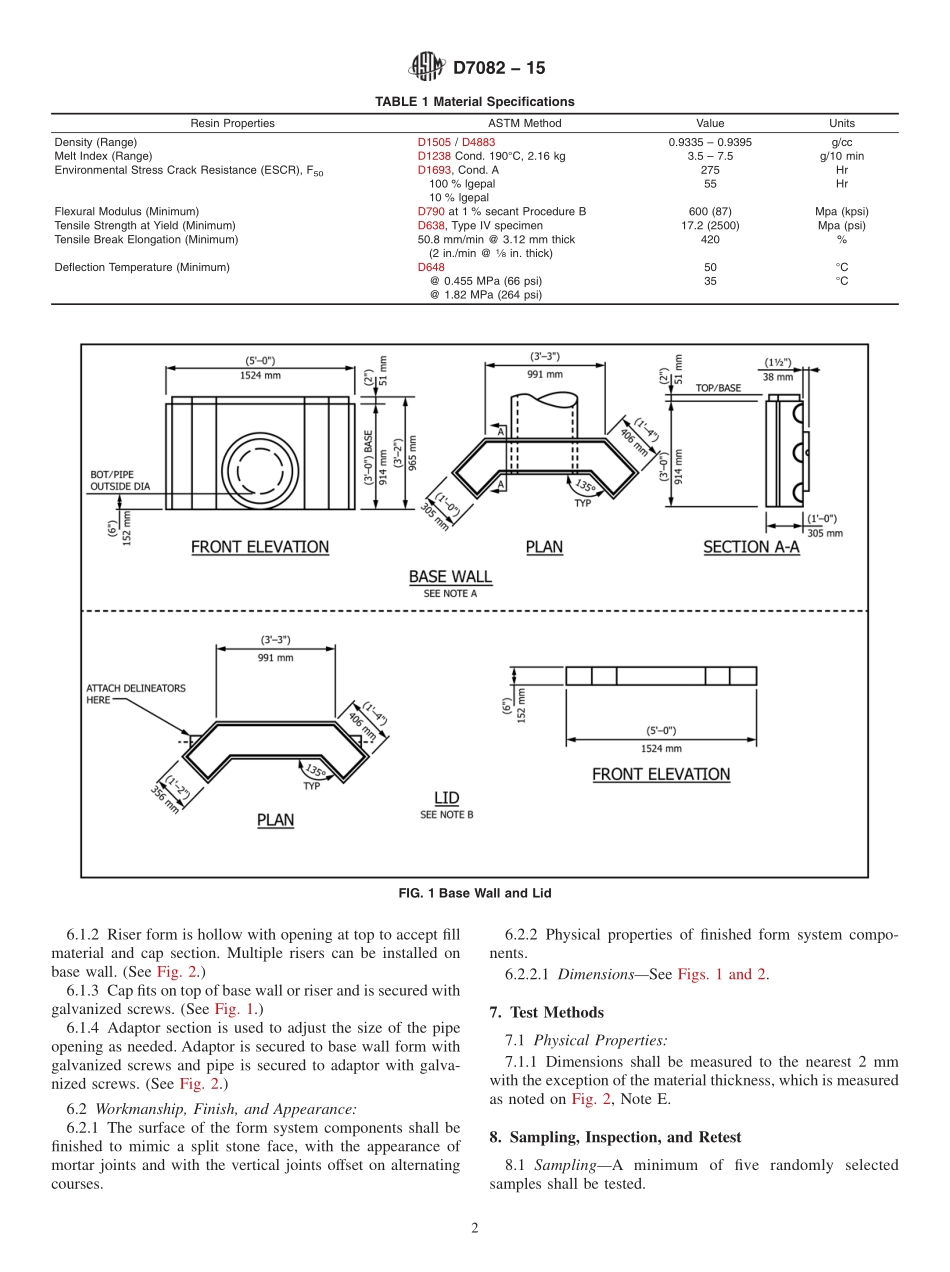

Designation:D7082−15AnAmericanNationalStandardStandardSpecificationforPolyethyleneStayInPlaceFormSystemforEndWallsforDrainagePipe1ThisstandardisissuedunderthefixeddesignationD7082;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationaddressestherequirementsforpoly-ethylenestayinplaceformsforendwallsorheadwallsforusewithstandardstormdrainagesystems.1.2Thewallformsystemconsistsofabasewallform,acap,anoptionalrisertoadjusttheheightofthewallabovethepipe,andanoptionaladaptortoadjustthepipeopeningtoaccommodatesmallerpipesizes.1.3Theformsystemismanufacturedusingtherotationalmoldingprocessandisavailableindifferentcolors.1.4ThevaluesstatedinSIunitsaretoberegardedasthestandard,theinch-poundsinparenthesesaregivenforinfor-mationonly.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatoryrequirementspriortouse.NOTE1—ThereisnoknownISOequivalenttothisstandard.2.ReferencedDocuments2.1ASTMStandards:2D638TestMethodforTensilePropertiesofPlasticsD648TestMethodforDeflectionTemperatureofPlasticsUnderFlexuralLoadintheEdgewisePositionD790TestMethodsforFlexuralPropertiesofUnreinforcedandReinforcedPlasticsandElectricalInsulatingMateri-alsD883TerminologyRelatingtoPlasticsD1238TestMethodforMeltFlowRatesofThermoplasticsbyExtrusionPlastometerD1505TestMethodforDensityofPlasticsbytheDensity-GradientTechniqueD1600TerminologyforAbbreviatedTermsRelatingtoPlas-ticsD1693TestMethodforEnvironmentalStress-CrackingofEthylenePlasticsD4883TestMethodforDensityofPolyethylenebytheUltrasoundTechnique3.Terminology3.1Definitions:3.1.1DefinitionsusedinthisspecificationareinaccordancewithdefinitionsinTerminologyD883andabbr...