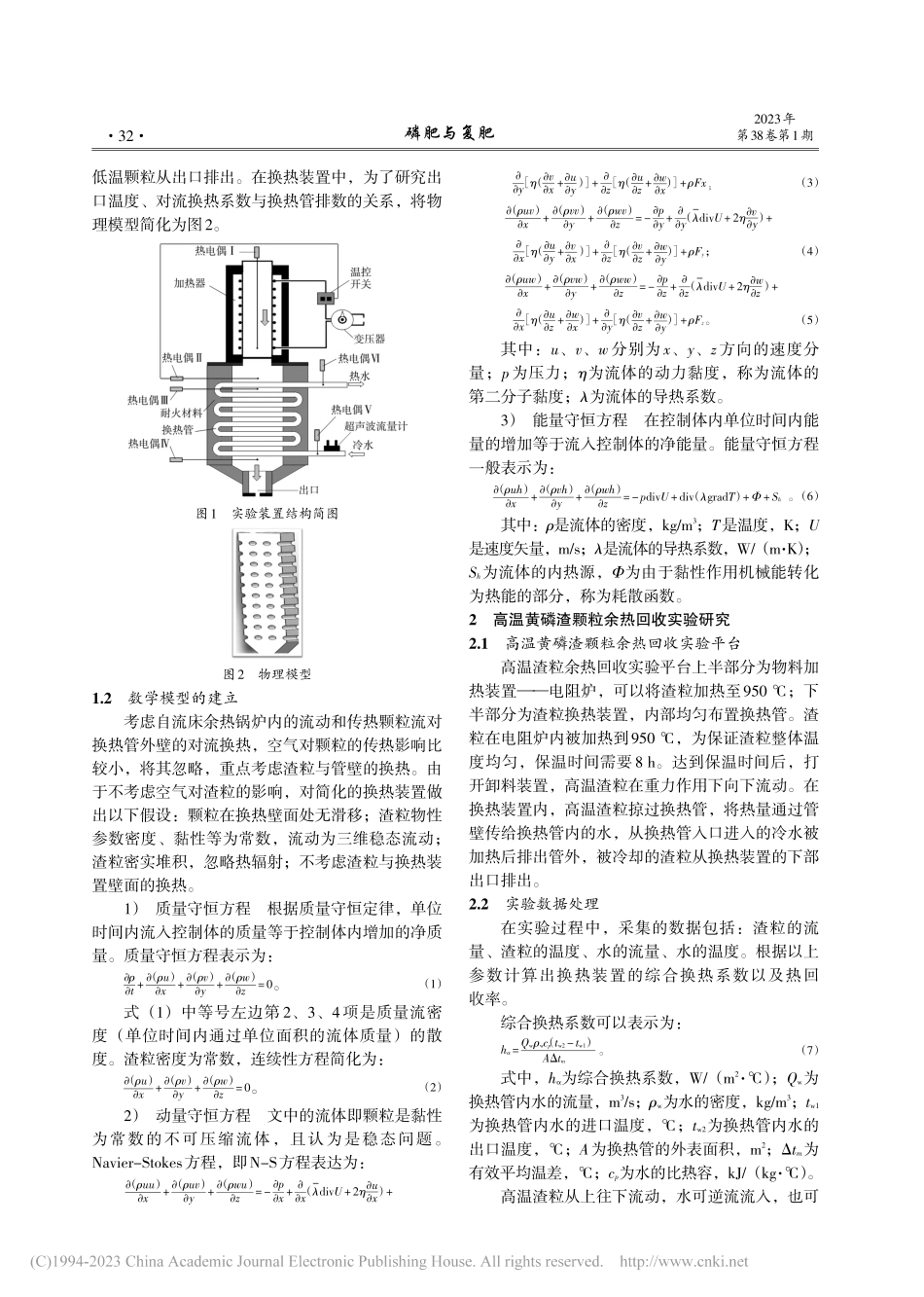

高温黄磷渣颗粒在余热锅炉内传热特性的模拟与实验研究胡祥东1,何苗1,郭英2(1.中节能工业节能有限公司,四川成都610000;2.重庆赛迪热工环保工程技术有限公司,重庆401122)[摘要]为了获得高温黄磷渣颗粒在余热锅炉内的传热特性,使用商用CFD软件Fluent研究高温黄磷渣颗粒在余热锅炉内的流动和换热问题,通过实验室实验研究渣粒流速、渣粒粒径、换热管间距对换热装置换热系数和热回收率的影响。结果表明:随着渣粒流速增加,换热装置的综合换热系数和热回收率逐渐增加;随着渣粒粒径增大,换热装置的综合换热系数和热回收率逐渐降低;随着换热管间距逐渐增加,换热装置的综合换热系数和热回收率逐渐降低。根据实验结果拟合了经验公式,为工程设计和应用提供借鉴。[关键词]黄磷渣颗粒;绕流圆管;传热特性;数值模拟[中图分类号]TQ126.3+1[文献标志码]A[文章编号]1007-6220(2023)01-0031-05SimulationandtestofheattransfercharacteristicsofhightemperatureyellowphosphorusslagparticlesinwasteheatboilerHUXiangdong1,HEMiao1,GUOYing2(1.CECEPIndustrialEnergyConservationCo.,Ltd.,Chengdu610000,China;2.ChongqingCISDIThermal&EnvironmentalEngineeringCo.,Ltd.,Chongqing401122,China)Abstract:ThecommercialCFDsoftwareFluentisusedtostudytheflowandheattransferofhightemperatureyellowphosphorusslagparticlesinwasteheatboiler.Throughlaboratoryexperiments,theeffectsofslagparticlevelocity,particlesizeandheatexchangetubespacingonheattransfercoefficientandheatrecoveryratearestudied.Theresultsshowthatwiththeincreaseofslagparticlevelocity,thecomprehensiveheattransfercoefficientandheatrecoveryrategraduallyincrease;Withtheincreaseofslagparticlesize,thecomprehensiveheattransfercoefficientandheatrecoveryrateofheatexchangergraduallydecrease;Withtheincreaseofheatexchangetubespacing,thecomprehensiveheattransfercoefficientandheatrecoveryrategraduallydecrease.Accordingtotheexperimentalresults,theempiricalformulaisfitted,whichcanprovidereferenceforengineeringdesignandapplication.Keywords:yellowphosphorusslagparticles;flowaroundcirculartube;heattransfercharacteristics;numericalsimulation[收稿日期]2022-06-01[作者简介]胡祥东(1972-),男,重庆人,...