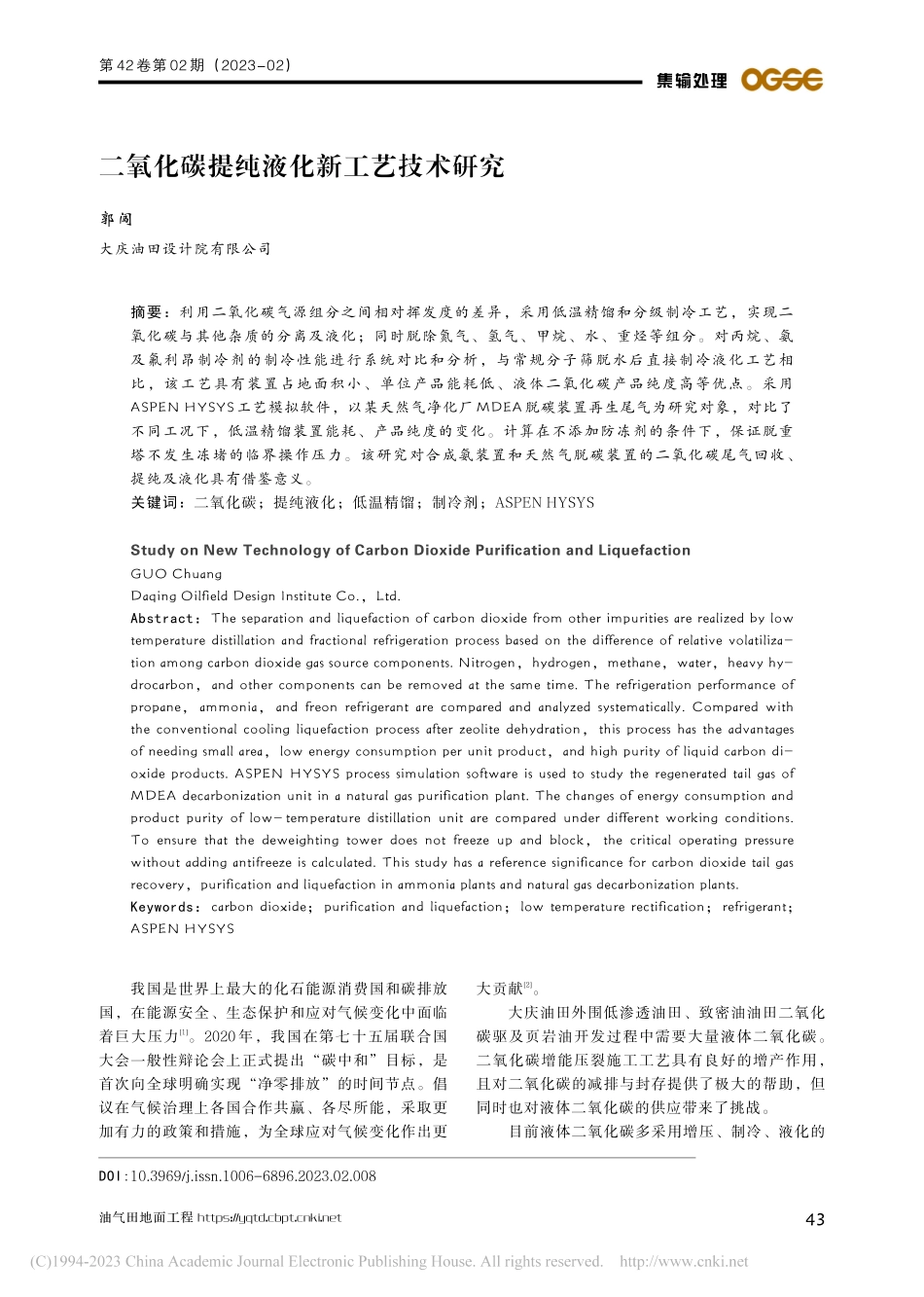

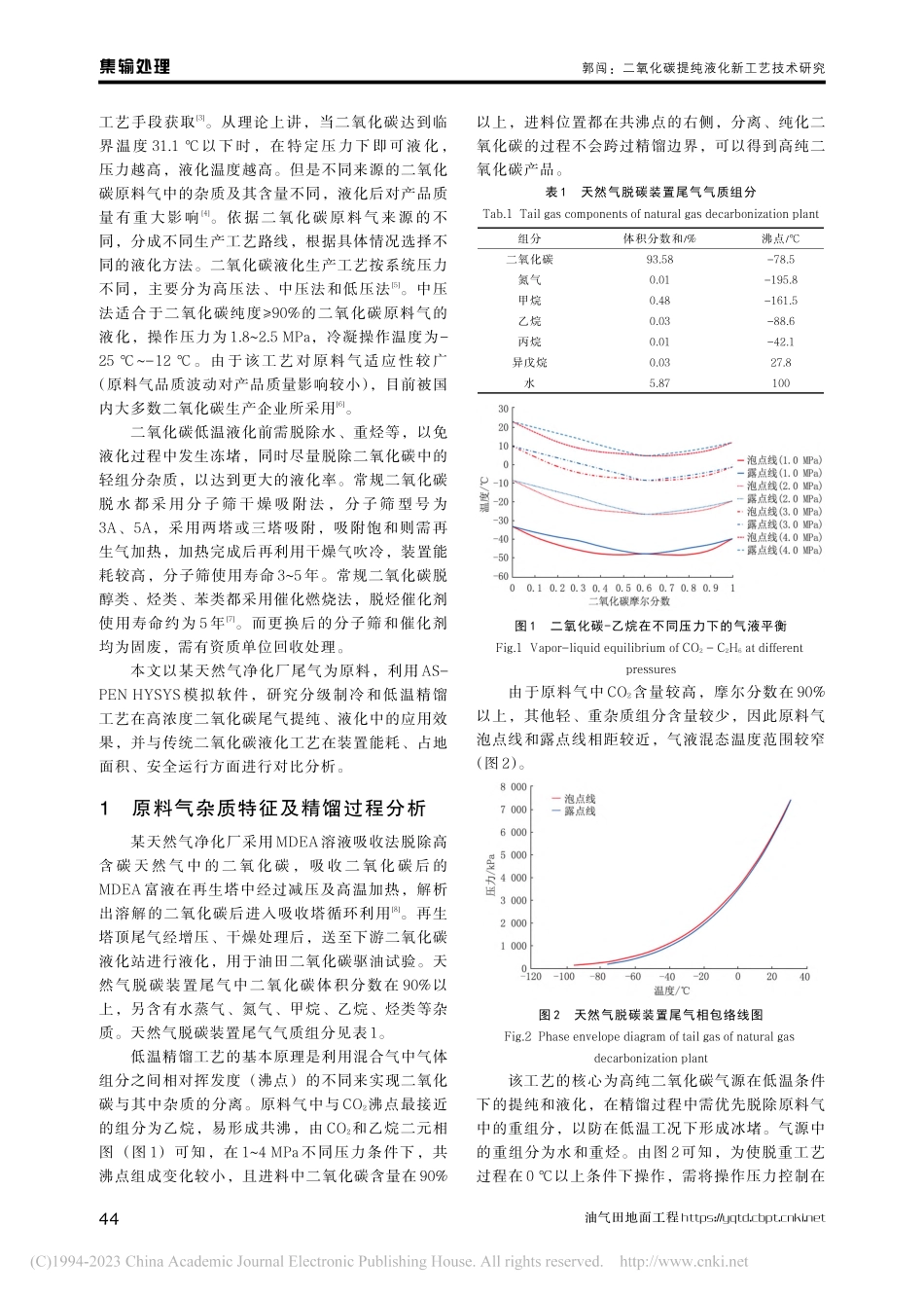

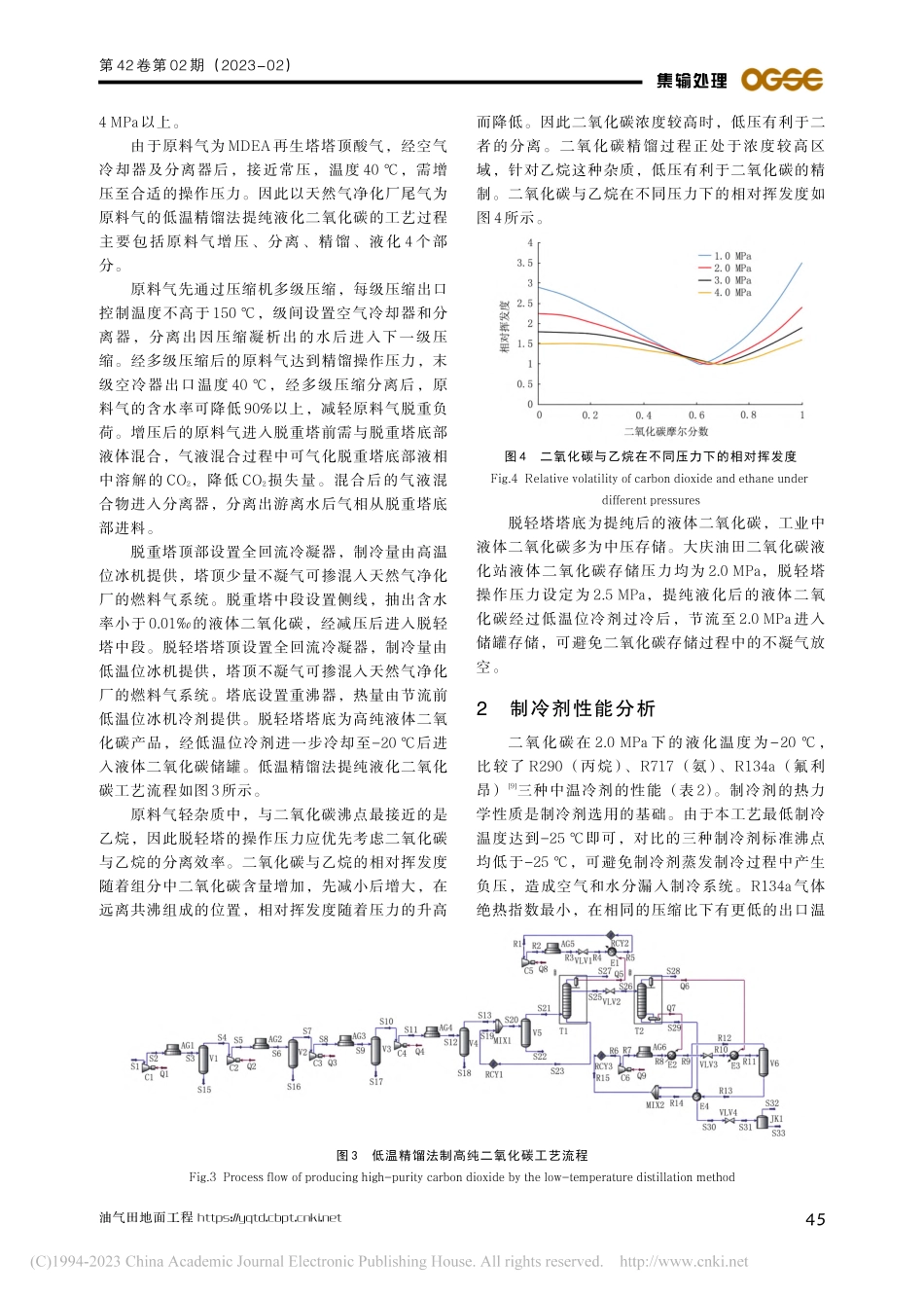

第42卷第02期(2023-02)油气田地面工程https://yqtd.cbpt.cnki.net集输处理二氧化碳提纯液化新工艺技术研究郭闯大庆油田设计院有限公司摘要:利用二氧化碳气源组分之间相对挥发度的差异,采用低温精馏和分级制冷工艺,实现二氧化碳与其他杂质的分离及液化;同时脱除氮气、氢气、甲烷、水、重烃等组分。对丙烷、氨及氟利昂制冷剂的制冷性能进行系统对比和分析,与常规分子筛脱水后直接制冷液化工艺相比,该工艺具有装置占地面积小、单位产品能耗低、液体二氧化碳产品纯度高等优点。采用ASPENHYSYS工艺模拟软件,以某天然气净化厂MDEA脱碳装置再生尾气为研究对象,对比了不同工况下,低温精馏装置能耗、产品纯度的变化。计算在不添加防冻剂的条件下,保证脱重塔不发生冻堵的临界操作压力。该研究对合成氨装置和天然气脱碳装置的二氧化碳尾气回收、提纯及液化具有借鉴意义。关键词:二氧化碳;提纯液化;低温精馏;制冷剂;ASPENHYSYSStudyonNewTechnologyofCarbonDioxidePurificationandLiquefactionGUOChuangDaqingOilfieldDesignInstituteCo.,Ltd.Abstract:Theseparationandliquefactionofcarbondioxidefromotherimpuritiesarerealizedbylowtemperaturedistillationandfractionalrefrigerationprocessbasedonthedifferenceofrelativevolatiliza-tionamongcarbondioxidegassourcecomponents.Nitrogen,hydrogen,methane,water,heavyhy-drocarbon,andothercomponentscanberemovedatthesametime.Therefrigerationperformanceofpropane,ammonia,andfreonrefrigerantarecomparedandanalyzedsystematically.Comparedwiththeconventionalcoolingliquefactionprocessafterzeolitedehydration,thisprocesshastheadvantagesofneedingsmallarea,lowenergyconsumptionperunitproduct,andhighpurityofliquidcarbondi-oxideproducts.ASPENHYSYSprocesssimulationsoftwareisusedtostudytheregeneratedtailgasofMDEAdecarbonizationunitinanaturalgaspurificationplant.Thechangesofenergyconsumptionandproductpurityoflow-temperaturedistillationunitarecomparedunderdifferentworkingconditions.Toensurethatthedeweightingtowerdoesnotfreezeupandblock,thecriticaloperatingpressurewithoutaddingantifreezeiscalculated.Thisstudyhasareferencesignificanceforcarbondioxidetailgasrecovery,purificationandliquefactioninammoniaplantsandnat...