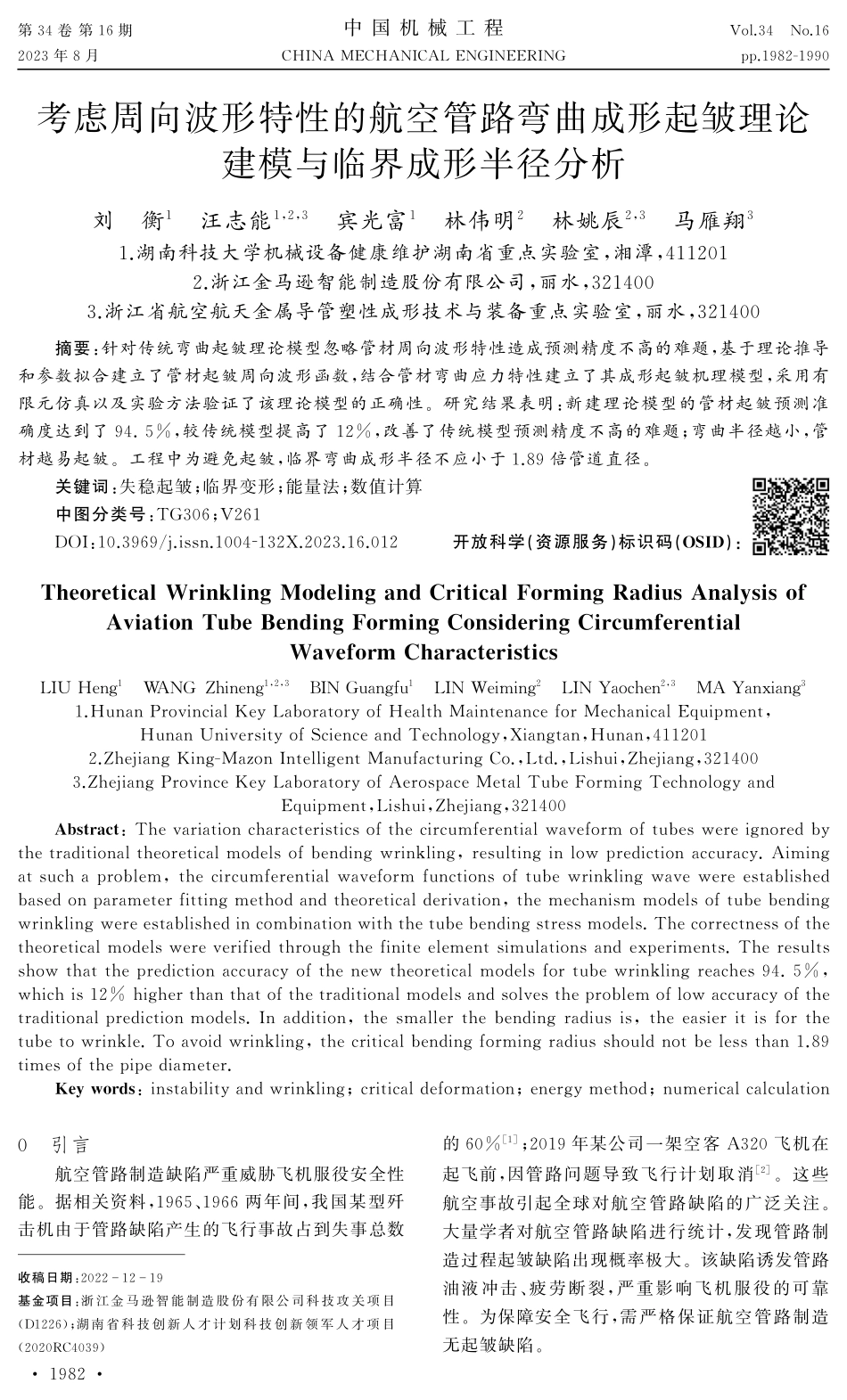

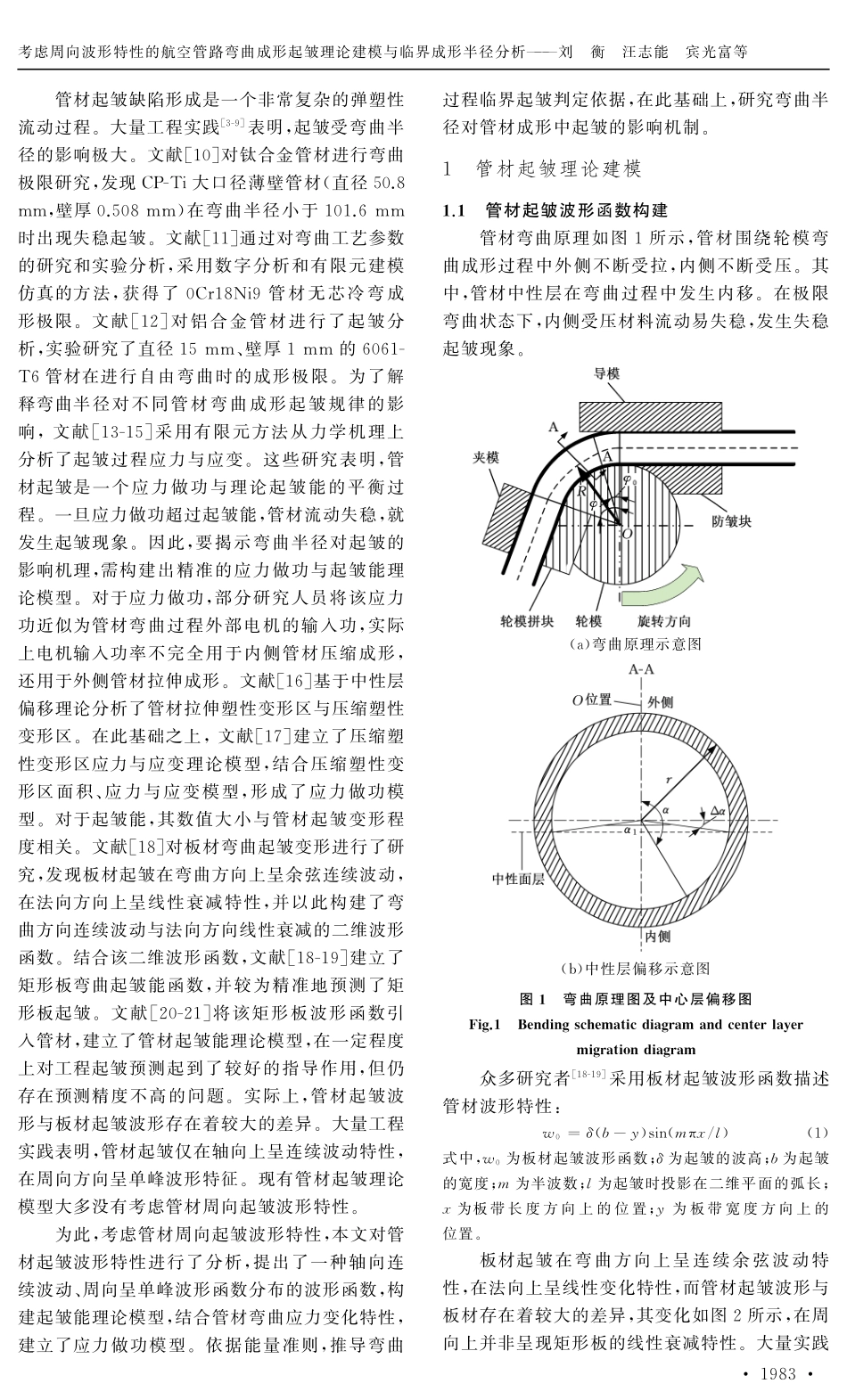

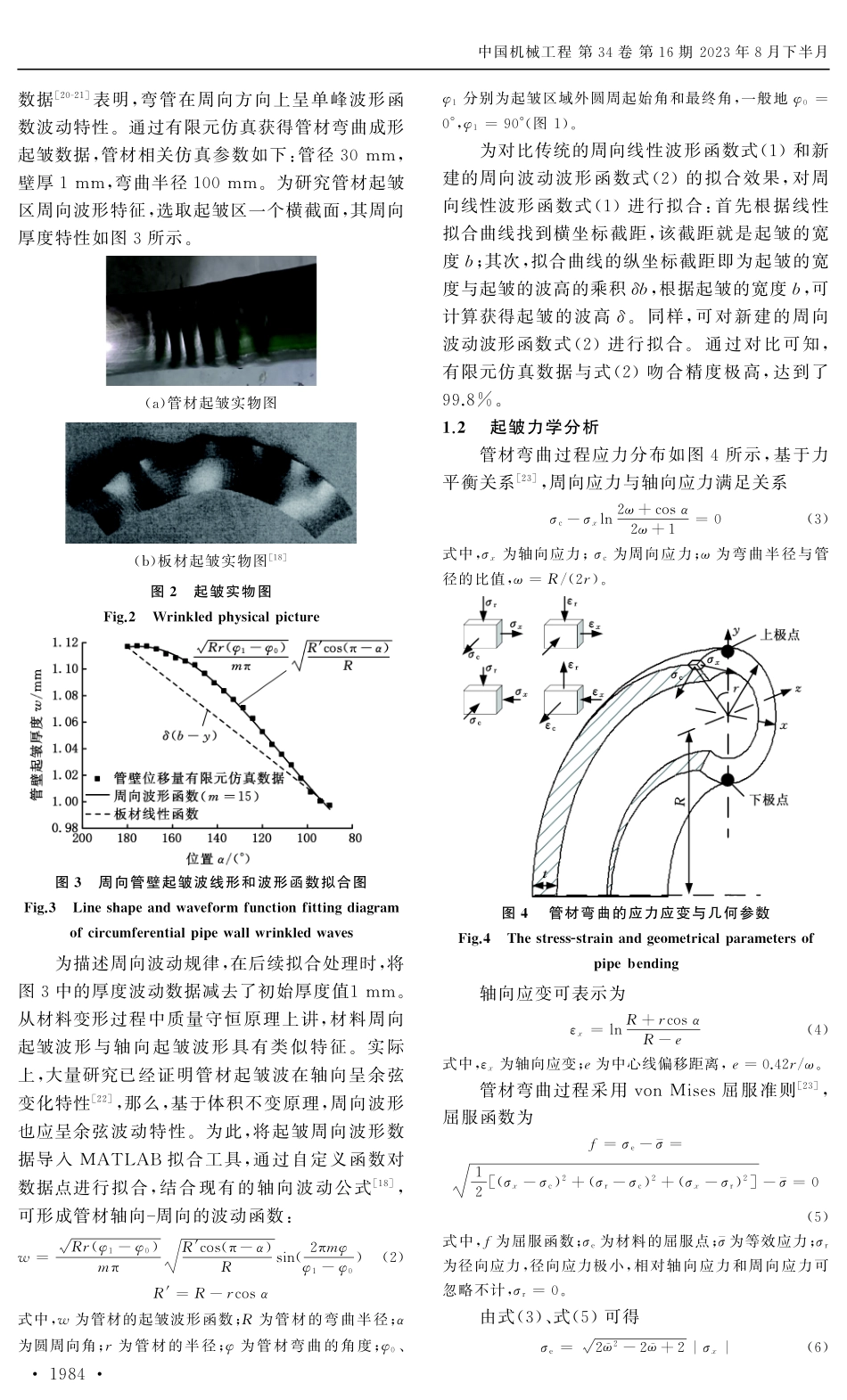

第34卷第16期中国机械工程Vol.34No.162023年8月CHINAMECHANICALENGINEERINGpp.1982G1990考虑周向波形特性的航空管路弯曲成形起皱理论建模与临界成形半径分析刘衡1汪志能1,2,3宾光富1林伟明2林姚辰2,3马雁翔31.湖南科技大学机械设备健康维护湖南省重点实验室,湘潭,4112012.浙江金马逊智能制造股份有限公司,丽水,3214003.浙江省航空航天金属导管塑性成形技术与装备重点实验室,丽水,321400摘要:针对传统弯曲起皱理论模型忽略管材周向波形特性造成预测精度不高的难题,基于理论推导和参数拟合建立了管材起皱周向波形函数,结合管材弯曲应力特性建立了其成形起皱机理模型,采用有限元仿真以及实验方法验证了该理论模型的正确性.研究结果表明:新建理论模型的管材起皱预测准确度达到了94.5%,较传统模型提高了12%,改善了传统模型预测精度不高的难题;弯曲半径越小,管材越易起皱.工程中为避免起皱,临界弯曲成形半径不应小于1.89倍管道直径.关键词:失稳起皱;临界变形;能量法;数值计算中图分类号:TG306;V261DOI:10.3969/j.issn.1004132X.2023.16.012开放科学(资源服务)标识码(OSID):TheoreticalWrinklingModelingandCriticalFormingRadiusAnalysisofAviationTubeBendingFormingConsideringCircumferentialWaveformCharacteristicsLIUHeng1WANGZhineng1,2,3BINGuangfu1LINWeiming2LINYaochen2,3MAYanxiang31.HunanProvincialKeyLaboratoryofHealthMaintenanceforMechanicalEquipment,HunanUniversityofScienceandTechnology,Xiangtan,Hunan,4112012.ZhejiangKingGMazonIntelligentManufacturingCo.,Ltd.,Lishui,Zhejiang,3214003.ZhejiangProvinceKeyLaboratoryofAerospaceMetalTubeFormingTechnologyandEquipment,Lishui,Zhejiang,321400Abstract:Thevariationcharacteristicsofthecircumferentialwaveformoftubeswereignoredbythetraditionaltheoreticalmodelsofbendingwrinkling,resultinginlowpredictionaccuracy.Aimingatsuchaproblem,thecircumferentialwaveformfunctionsoftubewrinklingwavewereestablishedbasedonparameterfittingmethodandtheoreticalderivation,themechanismmodelsoftubebendingwrinklingwereestablishedincombinationwiththetubebendingstressmodels.Thecorrectnessofthetheoretica...