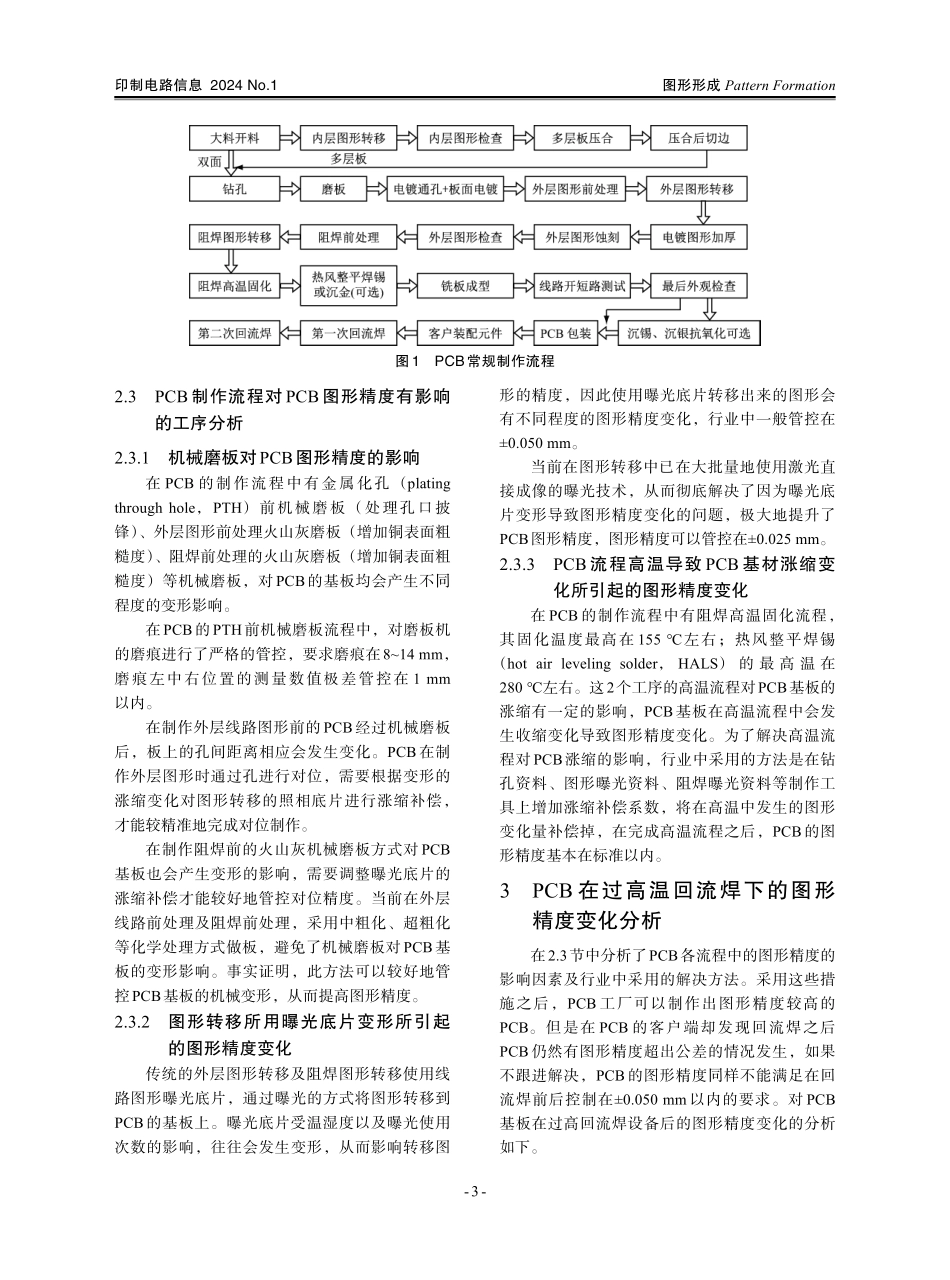

印制电路信息2024No.1图形形成PatternFormation回流焊设备在高图形精度PCB流程中的应用傅立红(广东依顿电子科技股份有限公司,广东中山528445)摘要印制电路板(PCB)基板在经过高温回流焊后均会发生不同程度的图形精度收缩变化。PCB的图形精度很难满足在装配元件前后管控±0.050mm的标准。通过研究PCB在回流焊高温后图形精度的变化规律,发现PCB的图形精度在第一次回流焊后变化量最大,第二次回流焊后的变化量较小。根据PCB基板的这个特性,在传统的PCB流程中导入回流焊设备,在把PCB交给客户之前,先将PCB在工厂内完成一次过回流焊处理。结果表明,PCB的图形精度在客户端回流焊前后的表现明显得到改善,在装配元件前后图形精度可管控在±0.050mm以内,达到了PCB的要求。关键词回流焊设备;图形精度;图形梯形精度中图分类号:TN41文献标志码:A文章编号:1009⁃0096(2024)01⁃0001⁃05ApplicationofreflowsolderingequipmentintheprocessofprintedcircuitboardwithhighgraphicaccuracyFULihong(GuangdongYidunElectronicTechnologyCo.,Ltd.,Zhongshan528445,Guangdong,China)AbstractAfterhightemperaturereflowsoldering,theprintedcircuitboard(PCB)substratewillshrinkindifferentdegrees,loweringthegraphicaccuracy.Itisdifficulttomeetthestandardofcontrollingtheaccuracywithin±0.050mmbeforeandafterassemblingcomponents.BystudyingthevariationlawofgraphicaccuracyofPCBafterreflowsolderingathightemperature,itisfoundthatthevariationofPCBgraphicaccuracyisthelargestafterthefirstreflowsoldering,andthevariationafterthesecondreflowsolderingissmaller.AccordingtothischaracteristicofPCBsubstrate,weintroducereflowsolderingequipmentinthetraditionalPCBprocess,beforethePCBishandedovertothecustomerinthePCBfactory.Afteronereflowsoldering,theperformanceofPCBgraphicaccuracybeforeandaftertheclientreflowsolderingisobviouslyimproved,thegraphicaccuracyofPCBbeforeandaftertheassemblyofcomponentsiscontrolledwithin0.050mm,whichcanmeettherequirements.Keywordsreflowsolderingequipment;graphicaccuracy;trapezoidalaccuracyofgraphics作者简介:傅立红(1973—),男,高级工程师,主要研究方向为PCB流程工艺及流程能力的提升、智能化自动化工厂规划。--1图形形成PatternFormation印制电路信息2024No...