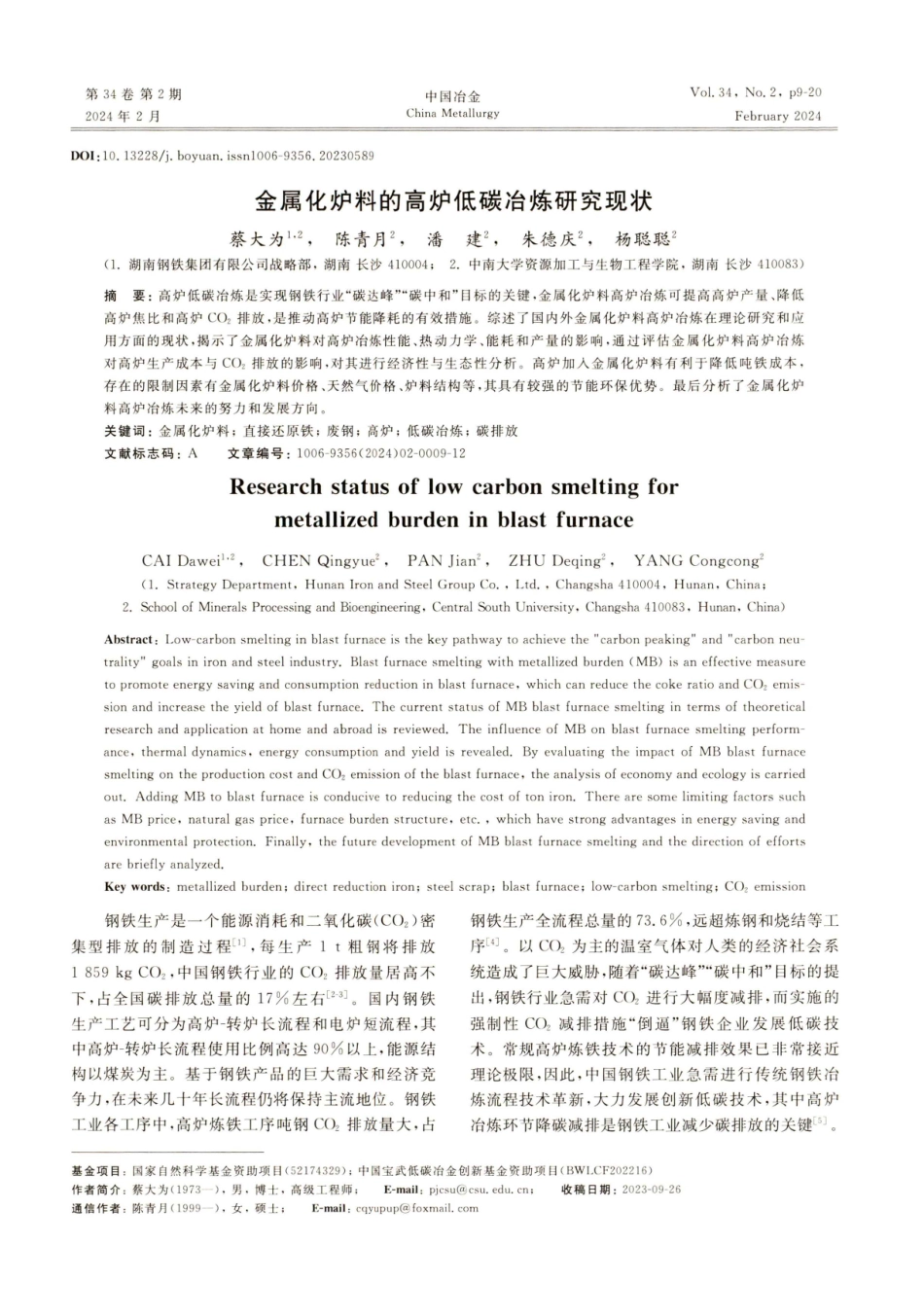

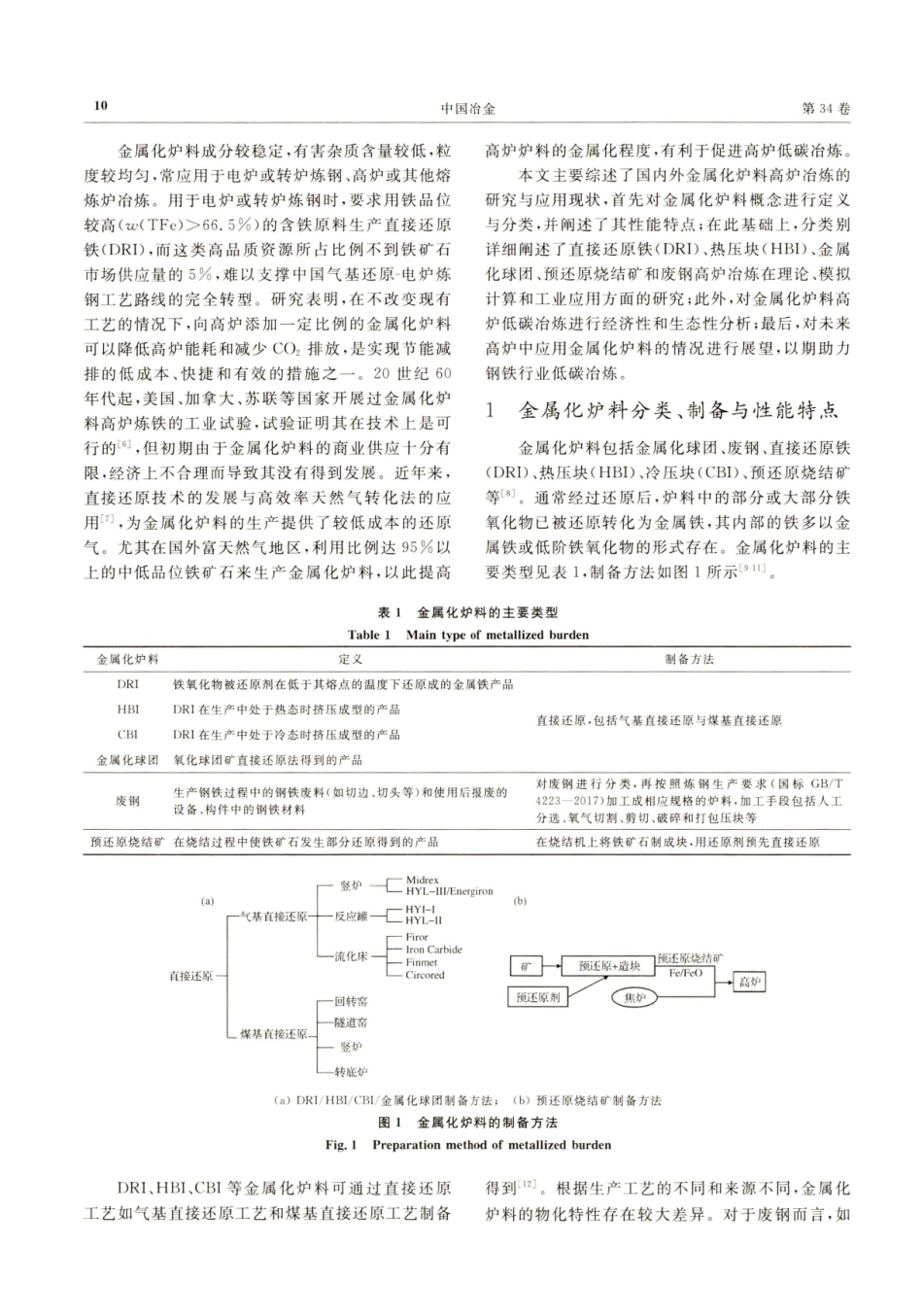

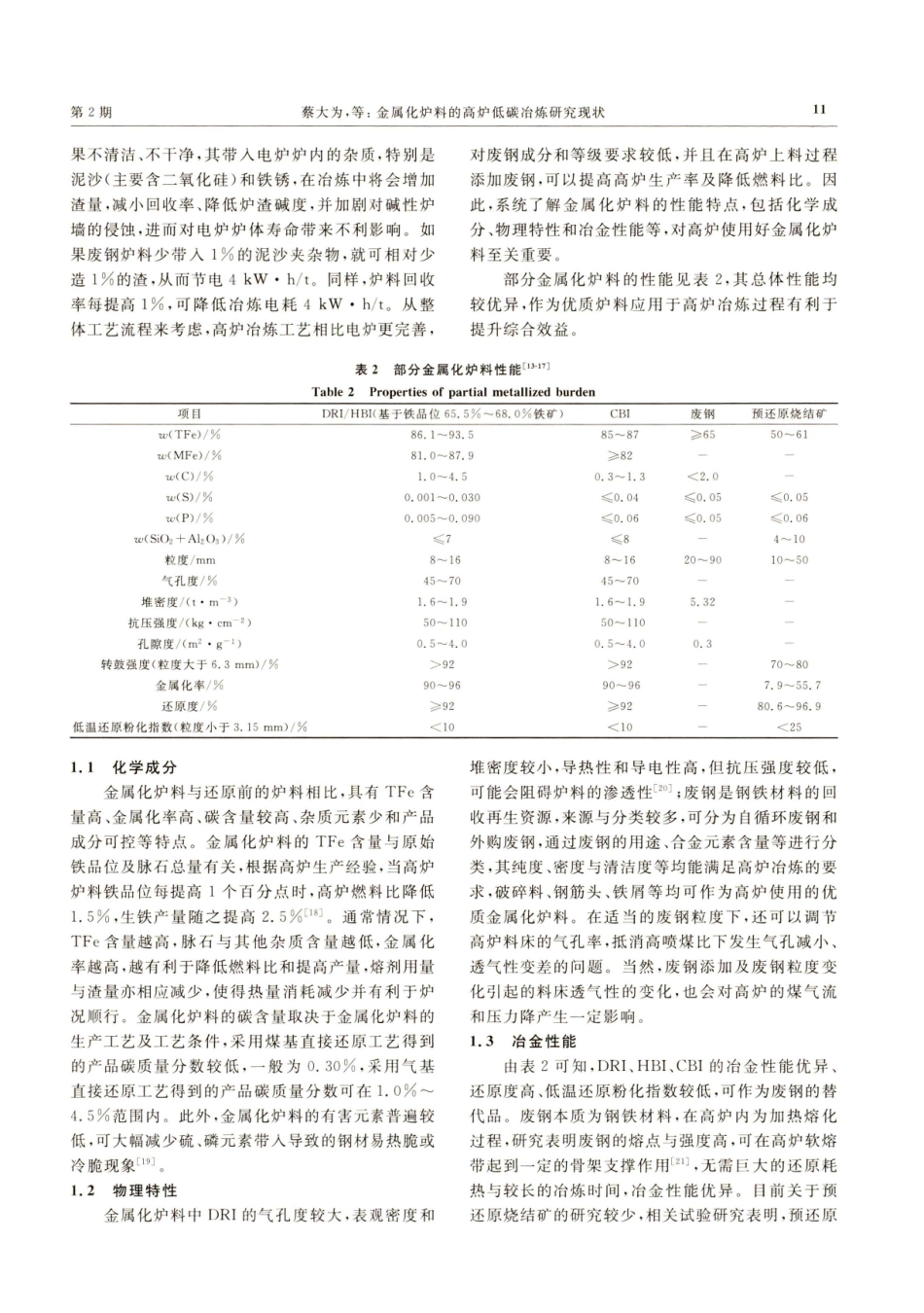

33)DOI:10.Sn1006-9356.202305893February20242024年2月ChinaMetallurgy中国冶金第34卷第2期Vol.34,No.2,p9-20金属化炉料的高炉低碳冶炼研究现状蔡大为1.2,陈青月²,潘建²,朱德庆?,杨聪聪2(1.湖南钢铁集团有限公司战略部,湖南长沙410004;22.中南大学资源加工与生物工程学院,湖南长沙41008摘要:高炉低碳冶炼是实现钢铁行业“碳达峰”“碳中和”目标的关键,金属化炉料高炉冶炼可提高高炉产量、降低高炉焦比和高炉CO2排放,是推动高炉节能降耗的有效措施。综述了国内外金属化炉料高炉冶炼在理论研究和应用方面的现状,揭示了金属化炉料对高炉冶炼性能、热动力学、能耗和产量的影响,通过评估金属化炉料高炉冶炼对高炉生产成本与CO2排放的影响,对其进行经济性与生态性分析。高炉加入金属化炉料有利于降低吨铁成本,存在的限制因素有金属化炉料价格、天然气价格、炉料结构等,其具有较强的节能环保优势。最后分析了金属化炉料高炉冶炼未来的努力和发展方向。关键词:金属化炉料;直接还原铁;废钢;高炉;低碳冶炼;碳排放文献标志码:A文章编号:1006-9356(2024)02-0009-12ResearchstatusoflowcarbonsmeltingformetallizedburdeninblastfurnaceCAIDaweil.2,CHENQingyue?,PANJian?,ZHUDeqing’,YANGCongcong?(1.StrategyDepartment,HunanIronandSteelGroupCo.,Ltd.,Changsha410004,Hunan,China;2.SchoolofMineralsProcessingandBioengineering,CentralSouthUniversity,Changsha410083,Hunan,China)Abstract:Low-carbonsmeltinginblastfurnaceisthekeypathwaytoachievethe"carbonpeaking"and"carbonneu-trality"goalsinironandsteelindustry.Blastfurnacesmeltingwithmetallizedburden(MB)isaneffectivemeasuretopromoteenergysavingandconsumptionreductioninblastfurnace,whichcanreducethecokeratioandCOzemis-sionandincreasetheyieldofblastfurnace.ThecurrentstatusofMBblastfurnacesmeltingintermsoftheoreticalresearchandapplicationathomeandabroadisreviewed.TheinfluenceofMBonblastfurnacesmeltingperform-ance,thermaldynamics,energyconsumptionandyieldisrevealed.ByevaluatingtheimpactofMBblastfurnacesmeltingontheproductioncostandCOzemissionoftheblastfurnace,theanalysisofeconomyandecologyiscarriedout.AddingMBtoblastfurnaceisconducivetoreducingthecostoftoniron.TherearesomelimitingfactorssuchasMBpr...