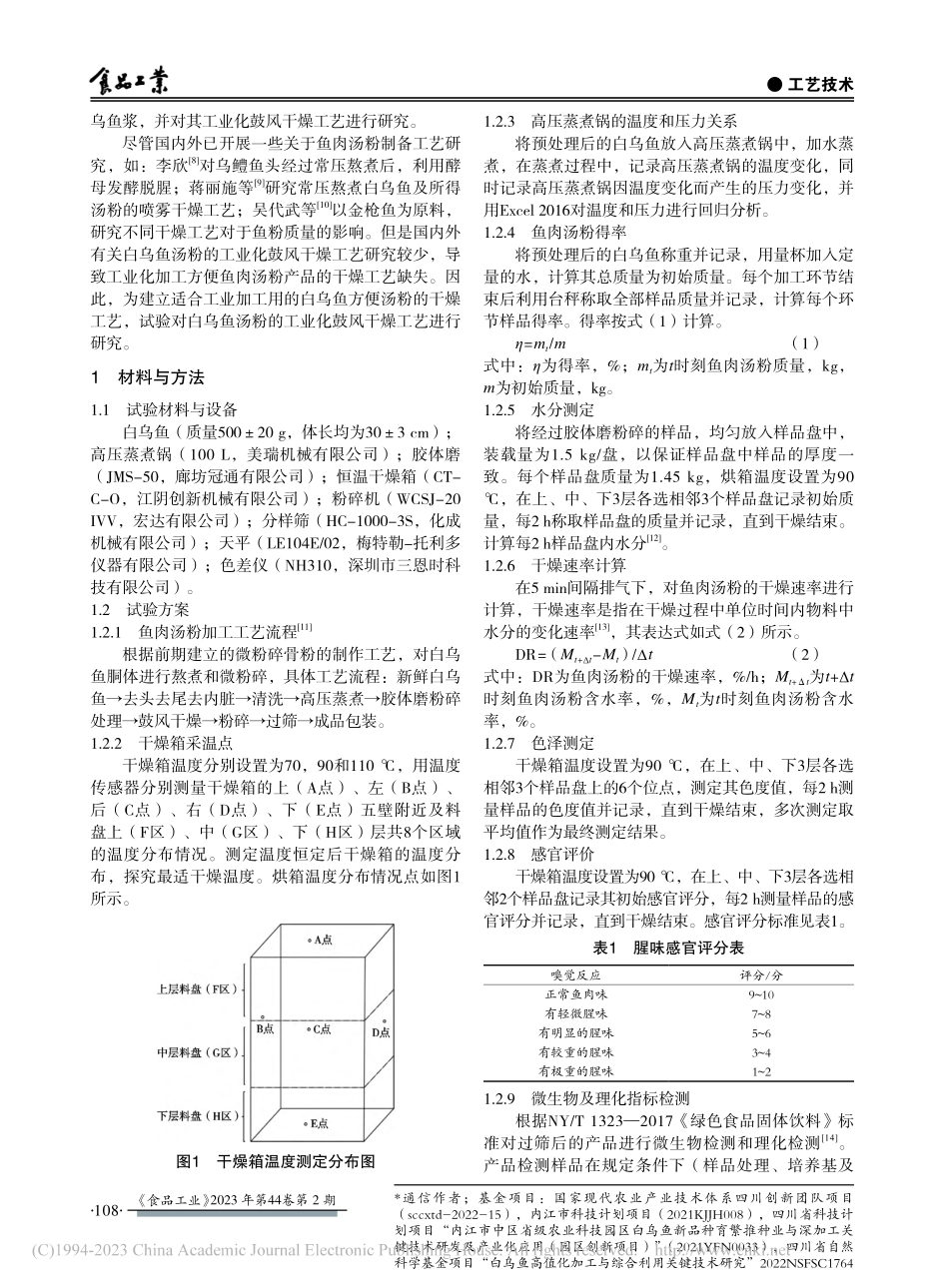

107工艺技术《食品工业》2023年第44卷第2期白乌鱼方便汤粉的工业化鼓风干燥工艺焦晓磊1,王林果2,母运龙1,张崟2*,邓语1,吴俊11.四川省内江市农业科学院(内江641099);2.成都大学肉类加工四川省重点实验室(成都610106)摘要为建立鱼肉方便汤粉的工业化鼓风干燥工艺,以白乌鱼为原料,在对其进行高压蒸煮和微粉碎基础上,采用鼓风干燥法对鱼浆进行干燥。通过测定干燥过程中鱼肉汤粉的水分、色度值、感官品质,以及干燥后鱼肉汤粉的理化指标和微生物菌落数,结果表明:鱼肉汤粉在干燥过程中水分与色度值(r=-0.866,P<0.01)、干燥时间(r=-0.979,P<0.01)均呈负相关;干燥时间与色度值呈正相关(r=0.768,P<0.05)。鱼肉汤粉的干燥速率随着干燥时间增加呈现先增大后降低趋势,上层和中层料盘的干燥速率较下层料盘较早达到峰值。在干燥温度90℃、干燥时间16h、5min间隔排气条件下,经过干燥后的鱼肉汤粉,其感官品质、微生物菌落数和理化指标均符合国家标准。关键词鱼肉方便汤粉;水分;色度值;相关性TheIndustrialBlastDryingProcessingofWhiteMullet(OpniocepnalusargusvarKimnra)ConvenientSoupPowderJIAOXiaolei1,WANGLinguo2,MUYunlong1,ZHANGYin2*,DENGYu1,WUJun11.NeijiangAcademyofAgriculturalSciences(Neijiang641099);2.KeyLaboratoryofMeatProcessingofSichuanProvince,ChengduUniversity(Chengdu610106)AbstractToestablishtheindustrialblastdryingprocessingoffishconvenientsouppowder,whitemullet(OpniocepnalusargusvarKimnra)wastakenasrawmaterialandprocessedwithhighpressurecookingandmicro-crushing,andthefishpulpwasthendriedwithindustrialblastdryingoven.Bymeasuringmoisture,chromaticvalueandsensoryqualityofthefishsoupinthedryingprocessing,andthemicrobialfloraandphysical-chemicalindexesofthedriedfishsouppowder,theresultsshowedthatthemoisturewasnegativelycorrelatedwithchromaticityvalue(r=0.866,P<0.01)andthedryingtime(r=-0.979,P<0.01),andthedryingtimewaspositivelycorrelated(r=0.768,P<0.05)withthechromaticityvalue,inthedryingprocessofthefishsouppowder.Thedryingrateofthefishsouppowderincreasedfirstlyandthendecreasedwiththeincreaseofdryingtime.Thedryingrateoftheupperandmiddletrayreachedatthepeakearlierthanthatofthelowertray.Inconclusion,underthedryingtemperatureof90℃,drying...