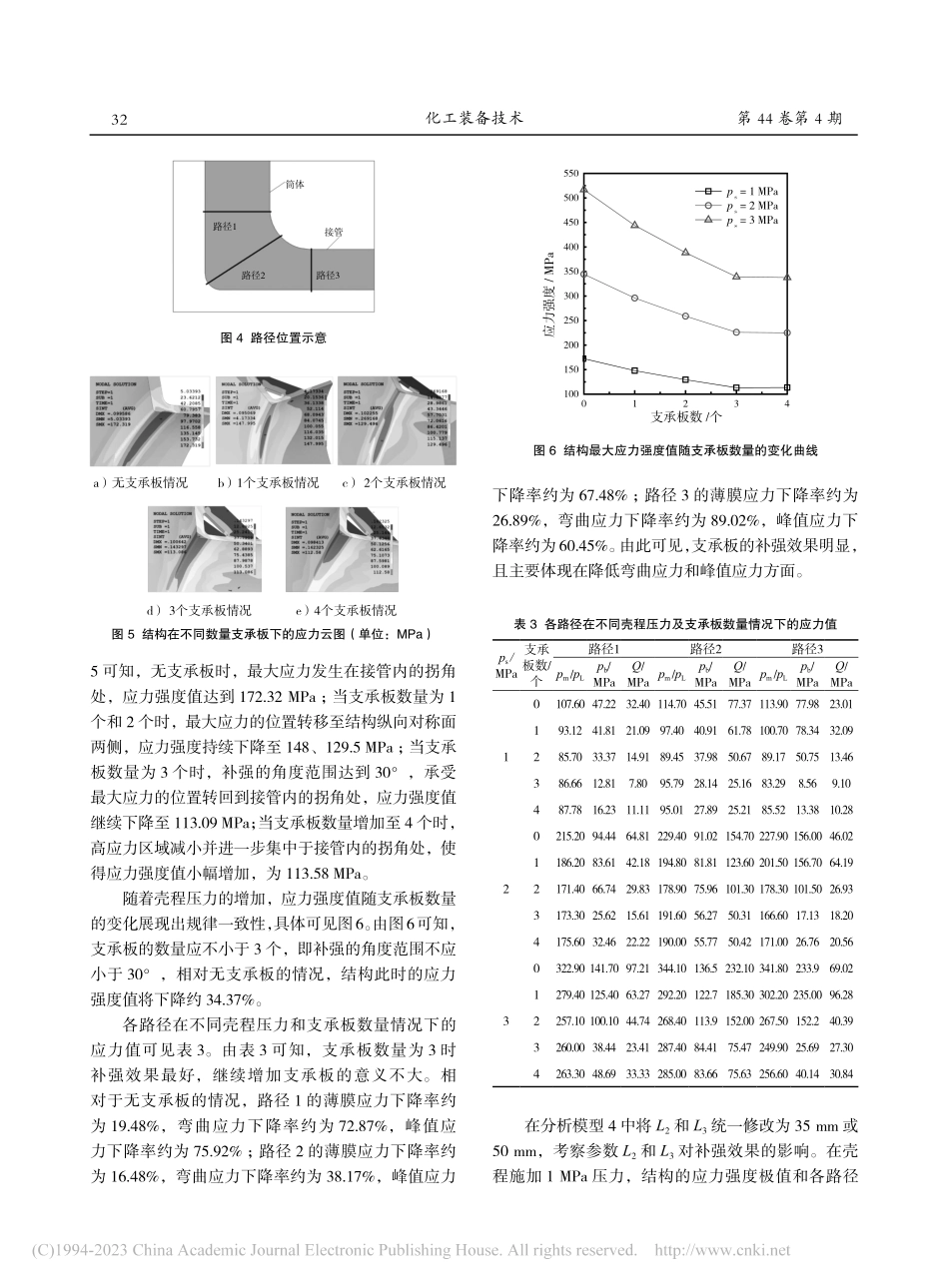

0引言在压力容器设计过程中,一般会采用一些补强措施来降低接管区域的应力集中程度,提高整个压力容器的承载能力。压力容器接管补强分为整体补强和补强圈补强,计算方法主要包括等面积法、压力面积法、分析法和有限元分析法[1-2]。根据已有文献的应力分析结果可知,整体补强、补强圈补强需要相对较大的壁厚,而厚壁将导致设备受到非常大的热应力作用,不利于设备整体结构的稳定[3-5]。因此,本文在不增加容器壁厚的前提下,提出采用支承板和套环的结构型式进行开孔补强,并利用有摘要为了解决压力容器开孔补强造成壁厚增加,进而在介质温度快速变化情况下出现结构不稳定的问题,提出了基于支承板和套环的补强结构型式,并采用ANSYS软件进行了分析和验证。结果显示:该补强结构型式可有效补强筒体开孔区域强度,降低该区域的应力水平,最大应力区域的膜应力最大可降低30%,弯曲应力最大可降低90%,峰值应力最大可降低70%;在补强贡献方面,支承板为主导,而套筒为有益补充;支承板在结构纵向对称面两侧布置的角度范围应不小于30°,其补强效果主要体现在降低弯曲应力和峰值应力方面。关键词压力容器开孔补强有限元ANSYS中图分类号TH49DOI:10.16759/j.cnki.issn.1007-7251.2023.08.008ReinforcementDesignfortheOpeningAreaofPressureVesselBarrelYANGYangFANJunAbstract:Inordertosolvetheproblemofincreasedwallthicknesscausedbythereinforcementofpressurevesselopenings,whichleadstothelossofstructuralstabilityunderrapidchangesinmediumtemperature,areinforcementstructurebasedonsupportplatesandringswasproposedandanalyzedandverifiedusingANSYSsoftware.Theresultsshowedthatthisreinforcementstructuretypecouldeffectivelystrengthenthestrengthoftheperforatedareaofthecylinder,reducethestresslevelinthisarea,andreducethemembranestressinthemaximumstressareabyupto30%,bendingstressbyupto90%,andpeakstressbyupto70%.Intermsofreinforcementcontribution,thesupportplatewasdominant,whilethesleevewasabeneficialsupplement.Theanglerangeofthesupportplatearrangedonbothsidesofthelongitudinalsymmetryplaneofthestructureshouldnotbelessthan30°,anditsreinforcementeffectwasmainlyreflectedinreducingbendingstressandpeakstress.Keywords:Pressurevessels;Openingreinforcement;Finiteelementanalysis;ANSYS杨洋*...