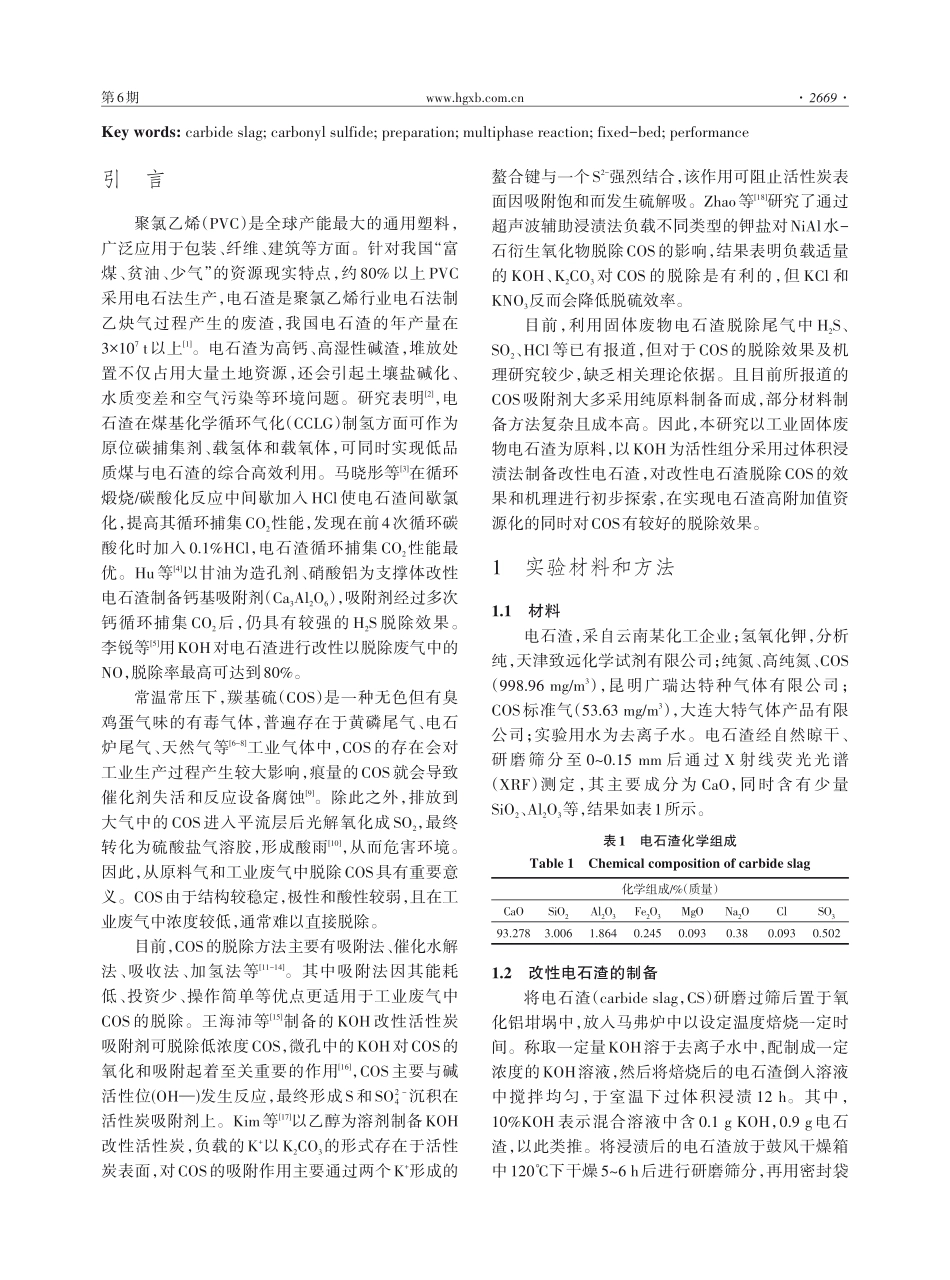

化工学报2023年第74卷第6期|,2023,74(6):2668-2679www.hgxb.com.cnCIESCJournalKOH改性电石渣脱除羰基硫的性能研究朱风1,陈凯琳1,黄小凤1,2,鲍银珠1,李文斌1,刘嘉鑫1,吴玮强1,高王伟1(1昆明理工大学环境科学与工程学院,云南昆明650500;2冶金及化工行业废气资源化国家地方联合工程研究中心,云南昆明650500)摘要:以电石渣为原料,采用过体积浸渍法制备KOH改性电石渣,考察了不同制备条件及工艺条件对脱除羰基硫(COS)的影响,并通过N2-BET、SEM-EDS、XPS、FTIR等方法进行表征,初步探究了改性电石渣的脱硫性能及反应过程,发现KOH改性电石渣脱除COS的过程中主要发生催化水解、氧化反应及酸碱吸附。结果表明,最佳制备条件为焙烧温度800℃、焙烧时间6h,KOH最适添加量为25%;在此条件下,当入口浓度、反应温度和空速分别为600mg/m3、25℃和5733h-1时,KOH改性电石渣脱除COS效果最佳,穿透吸附量为43.70mg/g。关键词:电石渣;羰基硫;制备;多相反应;固定床;性能中图分类号:X511;X754文献标志码:A文章编号:0438-1157(2023)06-2668-12PerformancestudyofKOHmodifiedcarbideslagforremovalofcarbonylsulfideZHUFeng1,CHENKailin1,HUANGXiaofeng1,2,BAOYinzhu1,LIWenbin1,LIUJiaxin1,WUWeiqiang1,GAOWangwei1(1FacultyofEnvironmentalScienceandEngineering,KunmingUniversityofScienceandTechnology,Kunming650500,Yunnan,China;2National-RegionalEngineeringCenterforRecoveryofWasteGasesfromMetallurgicalandChemicalIndustries,Kunming650500,Yunnan,China)Abstract:Inthispaper,KOHmodifiedcarbideslagwaspreparedbyexcessiveimpregnationusingcarbideslagasrawmaterial,andtheeffectsofdifferentKOHcontent(10%—30%),calcinationtemperature(700—900℃),calcinationtime(5—7h),carbonylsulfide(COS)inletconcentration(200—1000mg/m3),spacevelocity(5733—11404h-1),andreactiontemperature(25—75℃)ontheremovalofCOSwereinvestigated.ThedesulfurizationperformanceandreactionprocessofKOHmodifiedcarbideslagwerepreliminarilystudiedbyN2-BET,SEM-EDS,XPS,XRDandFTIR,anditwasfoundthatcatalytichydrolysis,oxidationreactionandacid-baseadsorptionmainlyoccurredintheprocessofCOSremovalwithKOHmodifiedcarbideslag.Theresultsshowedthattheoptimalpreparationconditionswerethecalcinationtemperatureof80...