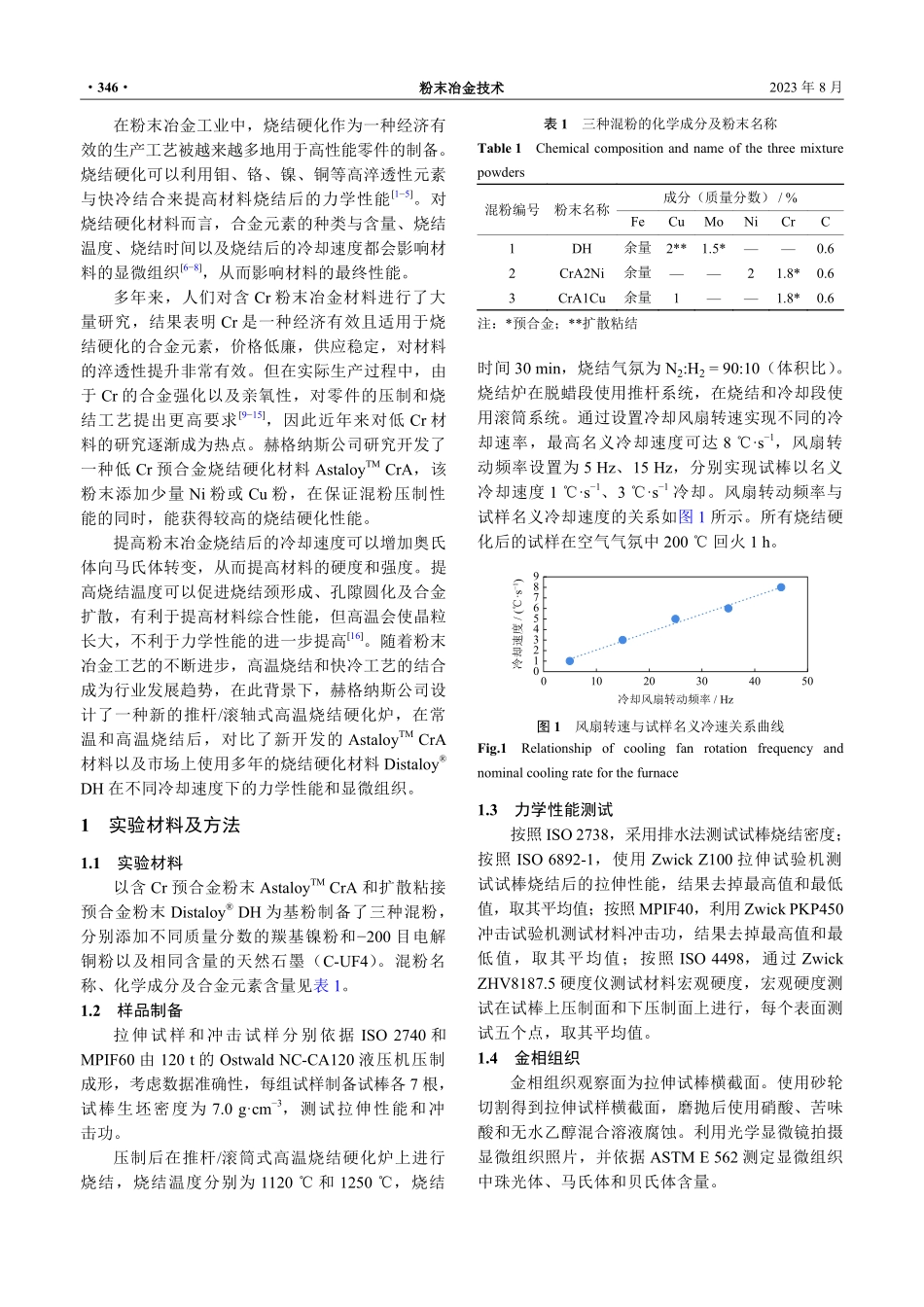

低铬粉末冶金烧结硬化钢的显微组织及力学性能杨洁✉,刘乐,黄晓琳赫格纳斯(中国)有限公司,上海201799✉通信作者,E-mail:ellin.yang@hoganas.com摘要烧结硬化作为一种经济有效的高强度粉末冶金零件生产工艺,可以通过控制烧结后冷却速度影响显微组织(马氏体含量),从而改善材料的最终性能。本文介绍了一种新开发的低Cr预合金烧结硬化材料AstaloyTMCrA,研究其在不同烧结温度和冷却速度下的力学性能和显微组织,并与常见的粉末冶金烧结硬化钢Distaloy®DH进行对比。研究表明,在压制密度为7.0g·cm−3并添加同等含量碳的条件下,添加质量分数2%Ni的AstaloyTMCrA混粉淬透性更高,获得比其他两种材料更高的马氏体含量及表观硬度。AstaloyTMCrA在1250℃烧结、冷却速度为3℃·s−1时,硬度最高达到HRC38;在1250℃烧结,冷却速度为1℃·s−1时,强度和韧性最佳。关键词粉末冶金;烧结硬化;微观组织;力学性能分类号TF121MicrostructureandmechanicalpropertiesofpowdermetallurgysinterhardeningsteelswithlowCrcontentYANGJie✉,LIULe,HUANGXiaolinHöganäsChinaCo.,Ltd.,Shanghai201799,China✉Correspondingauthor,E-mail:ellin.yang@hoganas.comABSTRACTSinterhardeningisanestablishedcost-effectiveprocesstoproducehighstrengthpowdermetallurgypartsbycontrollingthecoolingspeedtoaffectthesinteredmicrostructure(martensitecontent)toimprovethefinalperformance.Anewlydevelopedpre-alloysinterhardeningsteelswithlowCrcontent(AstaloyTMCrA)wasintroducedinthispaper,themechanicalpropertiesandmicrostructureunderthedifferentsinteringtemperatureandcoolingratewereinvestigated,andthecommonpowdermetallurgysinterhardeningmaterial(Distaloy®DH)wasreferencedforthecomparison.Intheresults,underthepressingdensityof7.0g·cm−3atthesamecarbonlevel,theAstaloyTMCrAaddedwith2%nickel(massfraction)hasthehighesthardenabilitywhichcanobtainthehighestmartensitecontentandthemacrohardnesscomparedtotheothermaterials.AstaloyTMCrAsinteredat1250℃andfollowedwiththecoolingrateof3℃·s−1canachievethehardnessofHRC38,whichcanobtaintheoptimumstrengthandtoughnessbysinteredatthesametemperatureandfollowedwiththelowercoolingrateof1℃·s−1.KEYWORDSpowdermetallurgy;sinterhardening;microstructure;mechani...