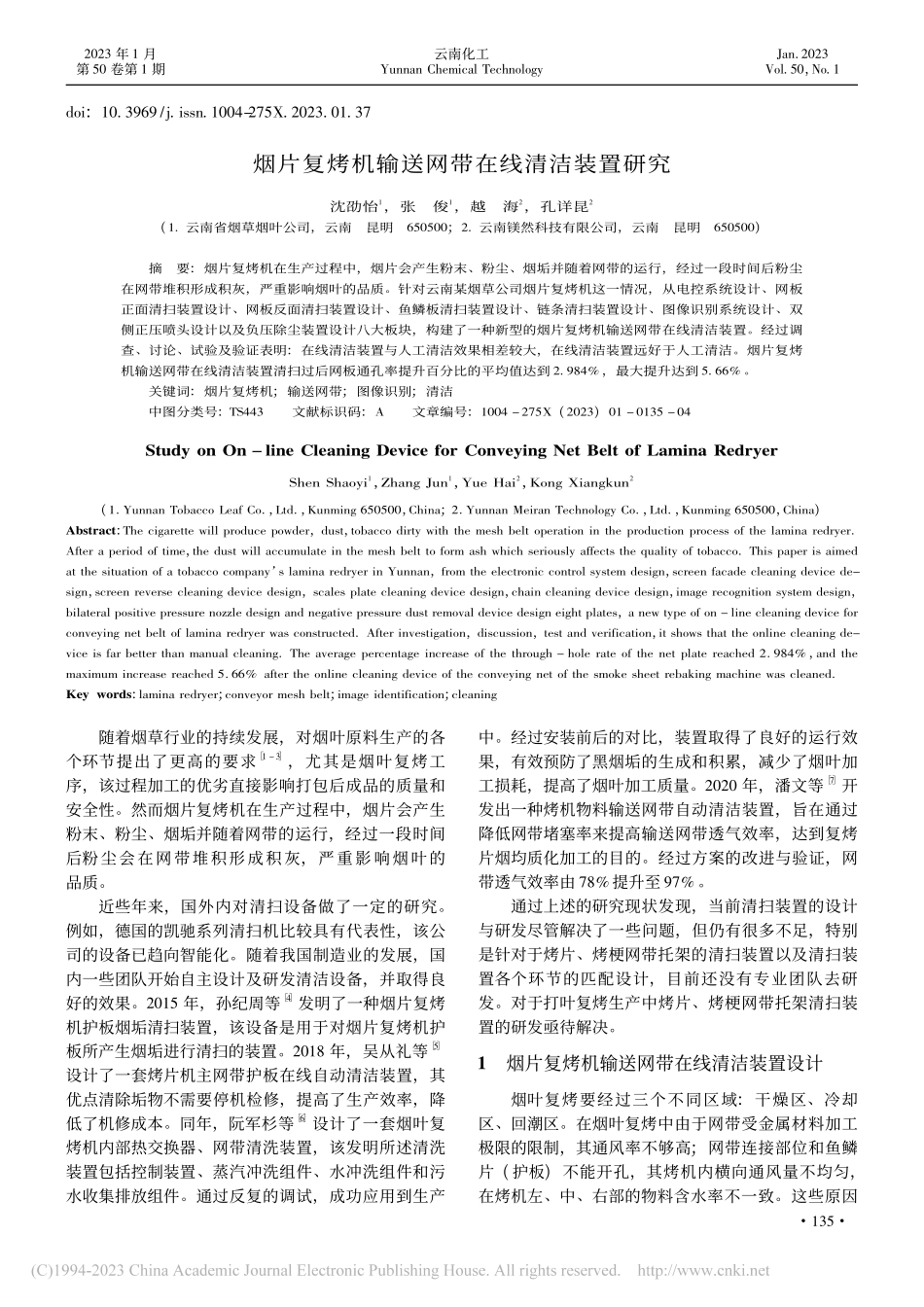

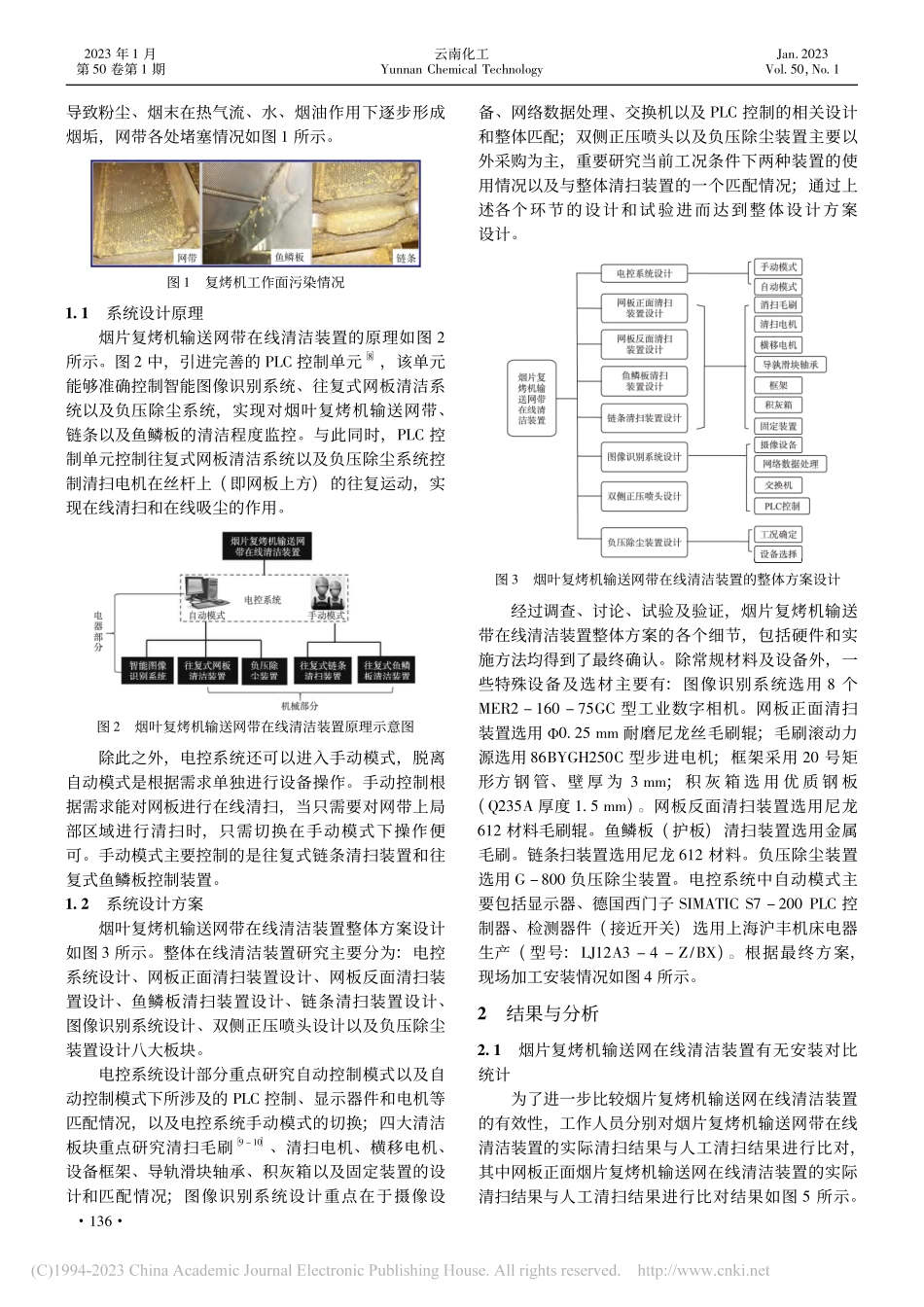

2023年1月云南化工Jan.2023第50卷第1期YunnanChemicalTechnologyVol.50,No.1doi:10.3969/j.issn.1004-275X.2023.01.37烟片复烤机输送网带在线清洁装置研究沈劭怡1,张俊1,越海2,孔详昆2(1.云南省烟草烟叶公司,云南昆明650500;2.云南镁然科技有限公司,云南昆明650500)摘要:烟片复烤机在生产过程中,烟片会产生粉末、粉尘、烟垢并随着网带的运行,经过一段时间后粉尘在网带堆积形成积灰,严重影响烟叶的品质。针对云南某烟草公司烟片复烤机这一情况,从电控系统设计、网板正面清扫装置设计、网板反面清扫装置设计、鱼鳞板清扫装置设计、链条清扫装置设计、图像识别系统设计、双侧正压喷头设计以及负压除尘装置设计八大板块,构建了一种新型的烟片复烤机输送网带在线清洁装置。经过调查、讨论、试验及验证表明:在线清洁装置与人工清洁效果相差较大,在线清洁装置远好于人工清洁。烟片复烤机输送网带在线清洁装置清扫过后网板通孔率提升百分比的平均值达到2.984%,最大提升达到5.66%。关键词:烟片复烤机;输送网带;图像识别;清洁中图分类号:TS443文献标识码:A文章编号:1004-275X(2023)01-0135-04StudyonOn-lineCleaningDeviceforConveyingNetBeltofLaminaRedryerShenShaoyi1,ZhangJun1,YueHai2,KongXiangkun2(1.YunnanTobaccoLeafCo.,Ltd.,Kunming650500,China;2.YunnanMeiranTechnologyCo.,Ltd.,Kunming650500,China)Abstract:Thecigarettewillproducepowder,dust,tobaccodirtywiththemeshbeltoperationintheproductionprocessofthelaminaredryer.Afteraperiodoftime,thedustwillaccumulateinthemeshbelttoformashwhichseriouslyaffectsthequalityoftobacco.Thispaperisaimedatthesituationofatobaccocompany’slaminaredryerinYunnan,fromtheelectroniccontrolsystemdesign,screenfacadecleaningdevicede-sign,screenreversecleaningdevicedesign,scalesplatecleaningdevicedesign,chaincleaningdevicedesign,imagerecognitionsystemdesign,bilateralpositivepressurenozzledesignandnegativepressuredustremovaldevicedesigneightplates,anewtypeofon-linecleaningdeviceforconveyingnetbeltoflaminaredryerwasconstructed.Afterinvestigation,discussion,testandverification,itshowsthattheonlinecleaningde-viceisfarbetterthanmanualcleaning.Theaveragepercentageincreaseofthethrough-holerateo...