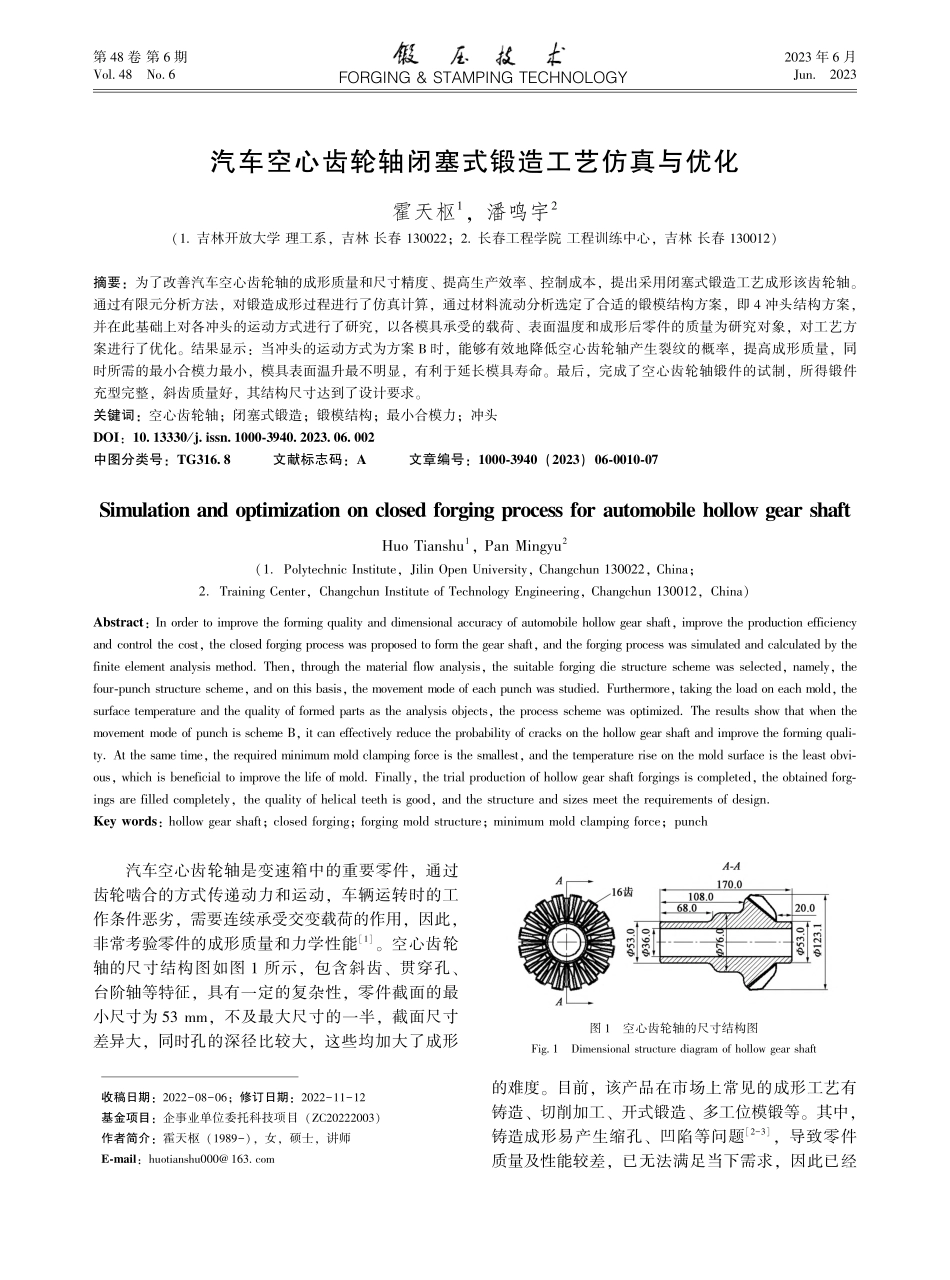

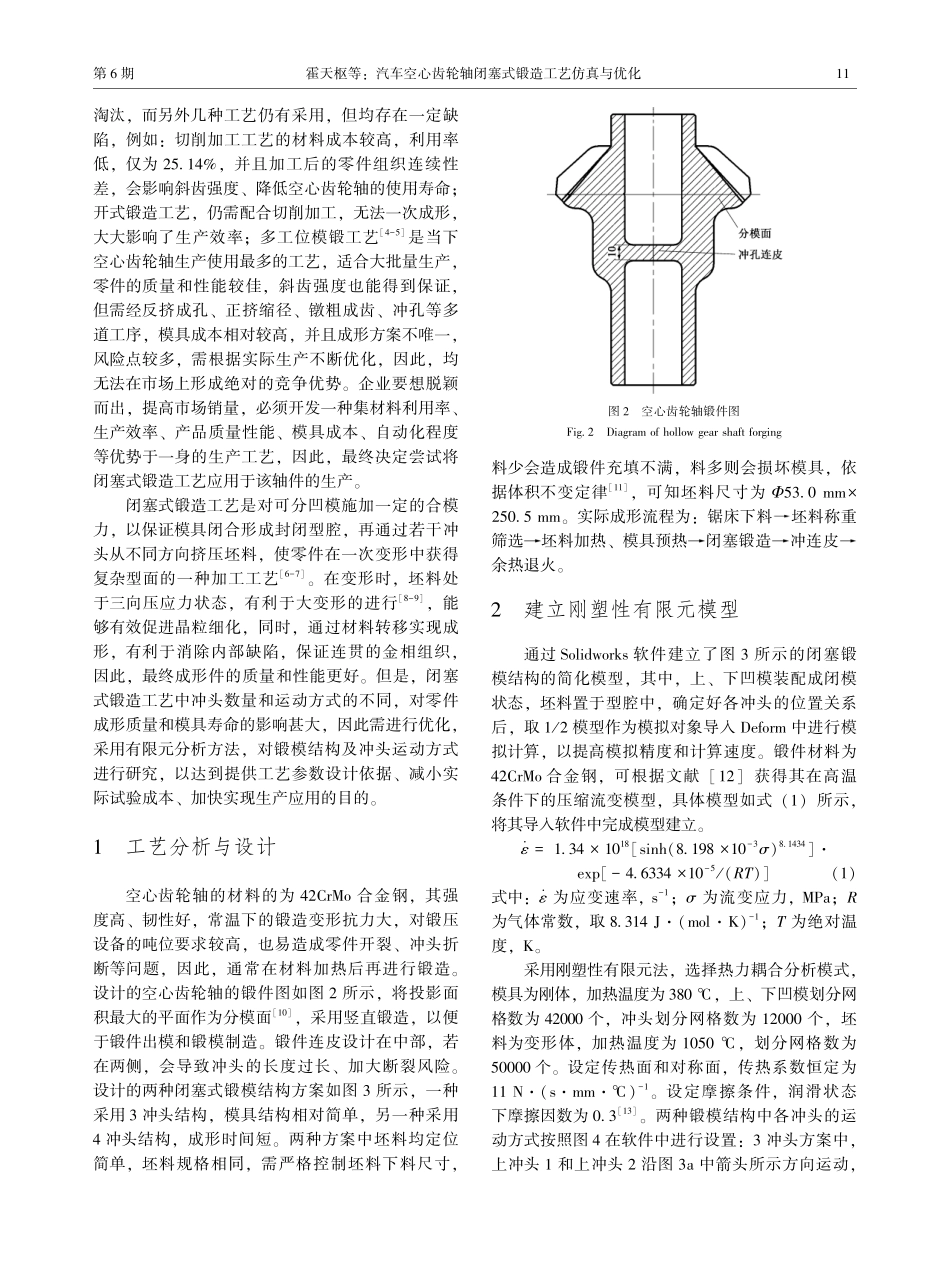

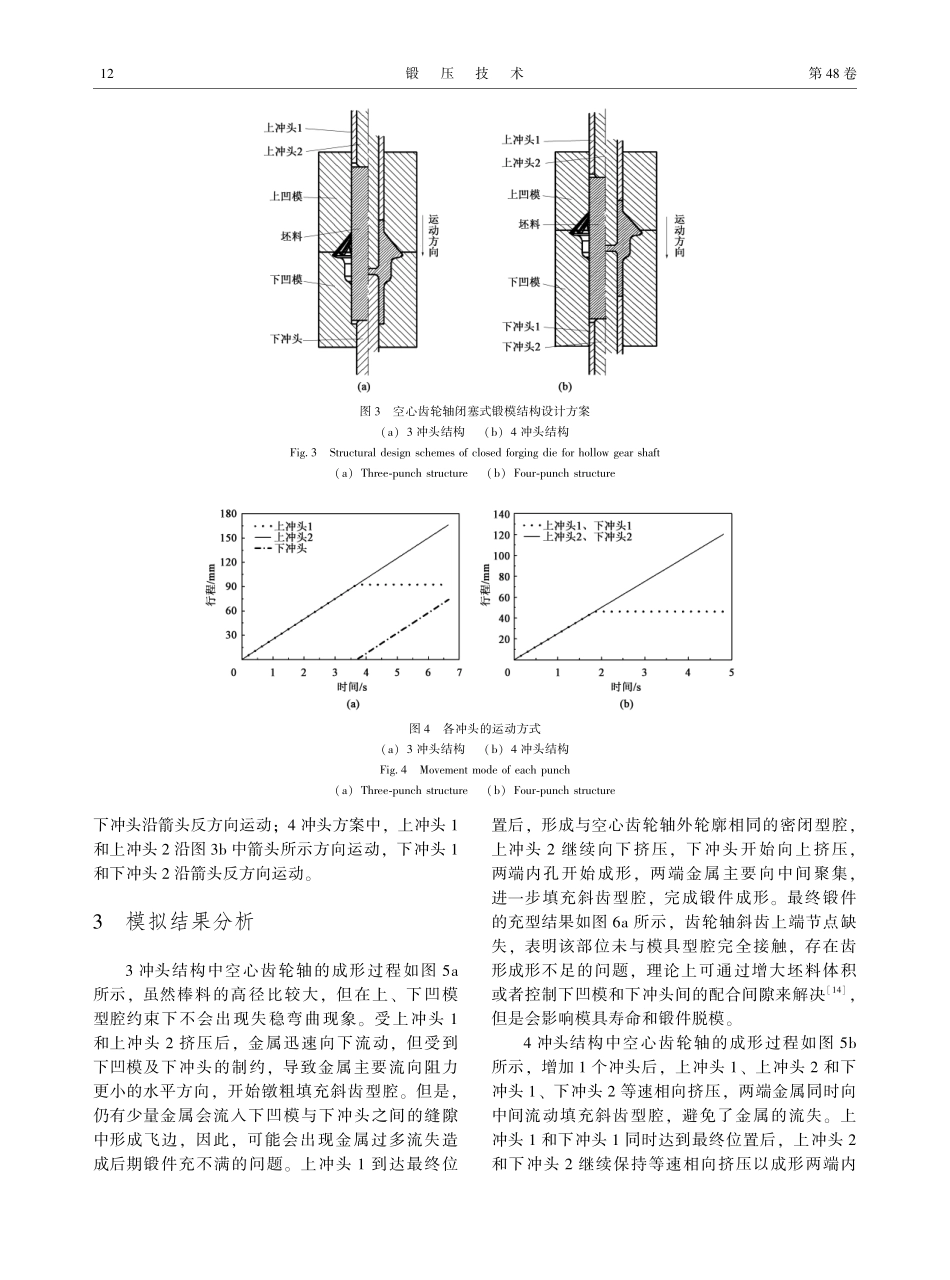

第48卷第6期Vol.48No.6FORGING&STAMPINGTECHNOLOGY2023年6月Jun.2023汽车空心齿轮轴闭塞式锻造工艺仿真与优化霍天枢1,潘鸣宇2(1.吉林开放大学理工系,吉林长春130022;2.长春工程学院工程训练中心,吉林长春130012)摘要:为了改善汽车空心齿轮轴的成形质量和尺寸精度、提高生产效率、控制成本,提出采用闭塞式锻造工艺成形该齿轮轴。通过有限元分析方法,对锻造成形过程进行了仿真计算,通过材料流动分析选定了合适的锻模结构方案,即4冲头结构方案,并在此基础上对各冲头的运动方式进行了研究,以各模具承受的载荷、表面温度和成形后零件的质量为研究对象,对工艺方案进行了优化。结果显示:当冲头的运动方式为方案B时,能够有效地降低空心齿轮轴产生裂纹的概率,提高成形质量,同时所需的最小合模力最小,模具表面温升最不明显,有利于延长模具寿命。最后,完成了空心齿轮轴锻件的试制,所得锻件充型完整,斜齿质量好,其结构尺寸达到了设计要求。关键词:空心齿轮轴;闭塞式锻造;锻模结构;最小合模力;冲头DOI:10.13330/j.issn.1000-3940.2023.06.002中图分类号:TG316.8文献标志码:A文章编号:1000-3940(2023)06-0010-07SimulationandoptimizationonclosedforgingprocessforautomobilehollowgearshaftHuoTianshu1,PanMingyu2(1.PolytechnicInstitute,JilinOpenUniversity,Changchun130022,China;2.TrainingCenter,ChangchunInstituteofTechnologyEngineering,Changchun130012,China)Abstract:Inordertoimprovetheformingqualityanddimensionalaccuracyofautomobilehollowgearshaft,improvetheproductionefficiencyandcontrolthecost,theclosedforgingprocesswasproposedtoformthegearshaft,andtheforgingprocesswassimulatedandcalculatedbythefiniteelementanalysismethod.Then,throughthematerialflowanalysis,thesuitableforgingdiestructureschemewasselected,namely,thefour-punchstructurescheme,andonthisbasis,themovementmodeofeachpunchwasstudied.Furthermore,takingtheloadoneachmold,thesurfacetemperatureandthequalityofformedpartsastheanalysisobjects,theprocessschemewasoptimized.TheresultsshowthatwhenthemovementmodeofpunchisschemeB,itcaneffectivelyreducetheprobabilityofcracksonthehollowgearshaftandimprovetheformingquali-ty.Atthesametime,therequiredminimummoldclampingforceisthesmallest,andthetemperatureriseonthemoldsurfaceisth...