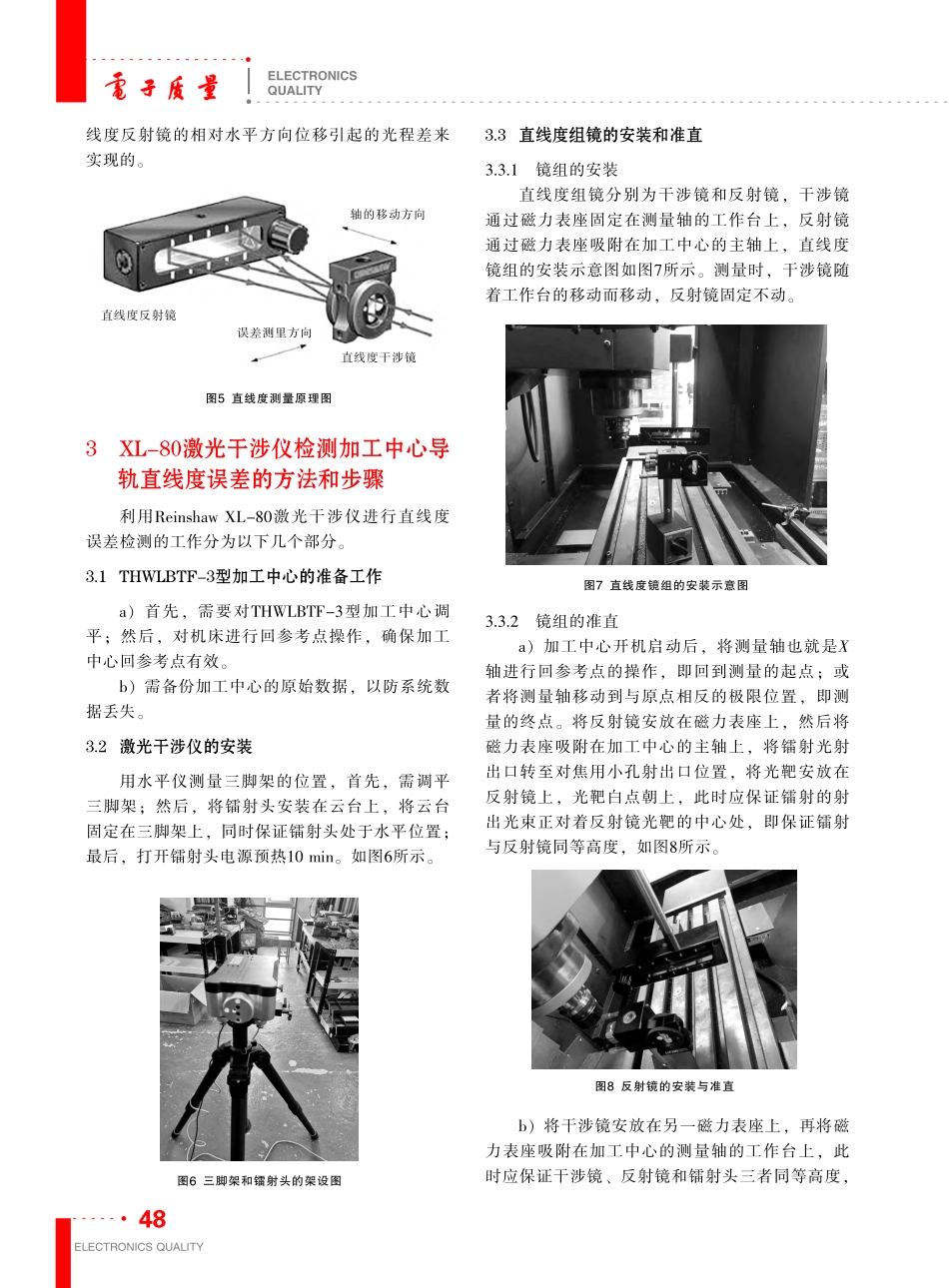

ELECTRONICSQUALITYELECTRONICSQUALITY基于XL-80激光干涉仪的直线度误差测量研究朱雅蓉,杨金国,杜文文(安徽芜湖技师学院,安徽芜湖241000)摘要:为了提高数控机床的位置精度,通常会检测数控机床导轨的直线度误差。但在检测数控机床导轨的直线度误差时,时常会限制测量范围和精度误差。通过ReinshawXL-80激光干涉仪可以实现对数控机床导轨的水平和垂直2个方位上的直线度测量。以THWLBTF-3型加工中心为试验平台,采用了ReinshawXL-80激光干涉仪,通过非接触和在线测量加工中心X轴的直线度误差;通过软件测得试验数据,绘制出最小二乘法曲线图和端点拟合法曲线图,结果表明:加工中心直线度误差的大小是影响数控机床加工精度的重要因素之一。关键词:XL-80激光干涉仪;THWLBTF-3型加工中心;直线度误差;直线度镜组中国分类号:TH744.3文献标识码:A文章编号:1003-0107(2023)06-0046-06doi:10.3969/j.issn.1003-0107.2023.06.011ResearchonStraightnessErrorMeasurementBasedonXL-80LaserInterferometerZHUYarong,YANGJinguo,DUWenwen(AnhuiWuhuTechnicianCollege,Wuhu241002,China)Abstract:InordertoimprovethepositionaccuracyofCNCmachinetools,thestraightnesserrorofCNCmachinetoolguiderailisusuallydetected.WhendetectingthestraightnesserrorofCNCmachinetoolsguiderail,themeasur-ingrangeandaccuracyerrorareoftenlimited.TheReinshawXL-80laserinterferometercanbeusedtothemeasure-mentofhorizontalandverticalstraightnessoftheguiderailofCNCmachinetools.TakingtheTHWLBTF-3machiningcenterasthetestplatform,ReinshawXL-80laserinterferometerisusedtomeasurethestraightnesserroroftheX-axisofthemachiningcenterbynon-contactandonline,andthetestdataaremeasuredthroughbysoftware,andtheleastsquarecurveandtheendpointfittingcurvearedrawn.TheresultsshowedthatthestraightnesserrorofmachiningcenterisoneoftheimportantfactorsaffectingthemachiningaccuracyofCNCmachinetools.Keywords:XL-80laserinterferometer;THWLBTF-3machiningcenter;straightnesserror;straightnessmirrorgroup收稿日期:2022-12-08作者简介:朱雅蓉(1992—),女,安徽芜湖人,安徽芜湖技师学院助理讲师,从事机械制造及工艺教育、数控加工及技术的教学和研究工作。通讯作者:杜文文(1988—),女,安徽当涂人,安徽机电...